CO2 laser tube

A technology of laser tube and tube body, applied in the field of CO2 laser tube, can solve the problem of unstable lens angle, and achieve the effect of improving spot quality, improving consistency and stability, and reducing dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

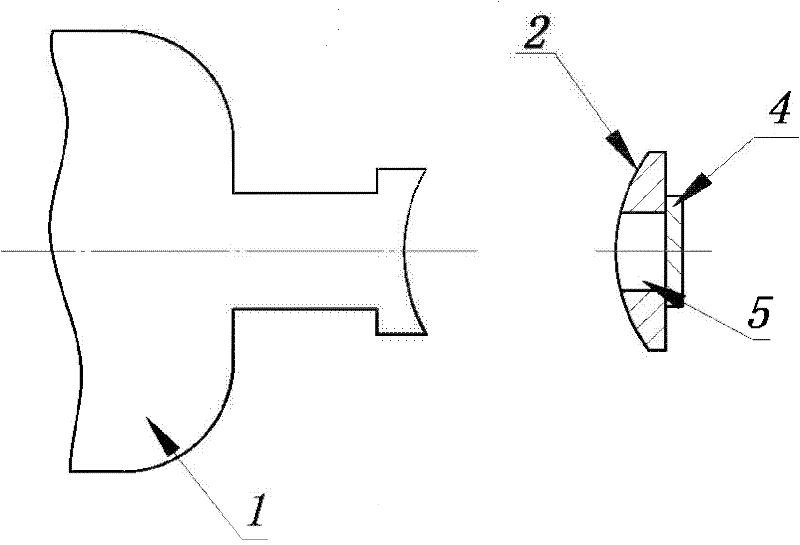

[0014] like figure 1 As shown, the CO2 laser tube includes a tube body 1 and a lens 4, and also includes a spherical mirror seat 2 and a light hole 5. The end face of the tube body 1 is mechanically or manually ground into a tube spherical surface, and the radius of the tube spherical surface is the same as that of the spherical mirror seat 2. The radius of the spherical surface is the same, and the concave and convex are opposite. The flat end of the spherical mirror base 2 is glued to the lens 4, and then glued together on the tube body 1. Due to the spherical contact, the direction can be adjusted arbitrarily, and it is very easy to adjust the angle of the spherical mirror base to drive the lens 4. It is perpendicular to the axis line of the pipe body 1. Since the end face of the pipe body can be selected and preferably mechanically ground, the problem of insufficient flatness of the original manual grinding is avoided. Because it is a spherical contact, any angle can be adj...

Embodiment 2

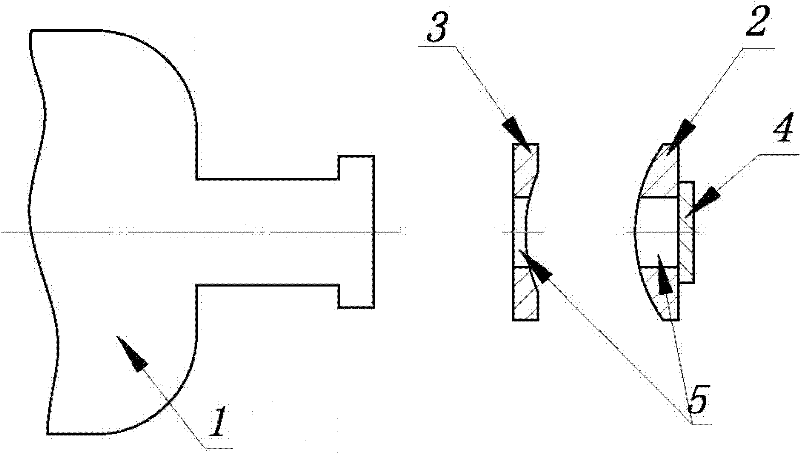

[0016] like figure 2 As shown, the CO2 laser tube includes a tube body 1 and a lens 4, and also includes a spherical mirror seat 2, a spherical connecting frame 3 and a light hole 5. The end face of the tube body 1 is ground into a plane by mechanical or manual methods, and the spherical connecting frame 3 One end of the plane is bonded to it, and the other side of the spherical connecting frame is a spherical surface, and its spherical radius is the same as that of the spherical mirror base 2, and the concave and convex are opposite. Also, due to the spherical contact, it can be adjusted at any angle so that the lens 4 is perpendicular to the axis of the tube body 1. Since the end surface of the tube body 1 can be mechanically ground, the spherical mirror seat 2 and the spherical connecting frame 3 are all made of a CNC lathe. Finished, it also avoids many problems in manual operation, greatly increases the laser output power, improves the quality of the spot, reduces the de...

Embodiment 3

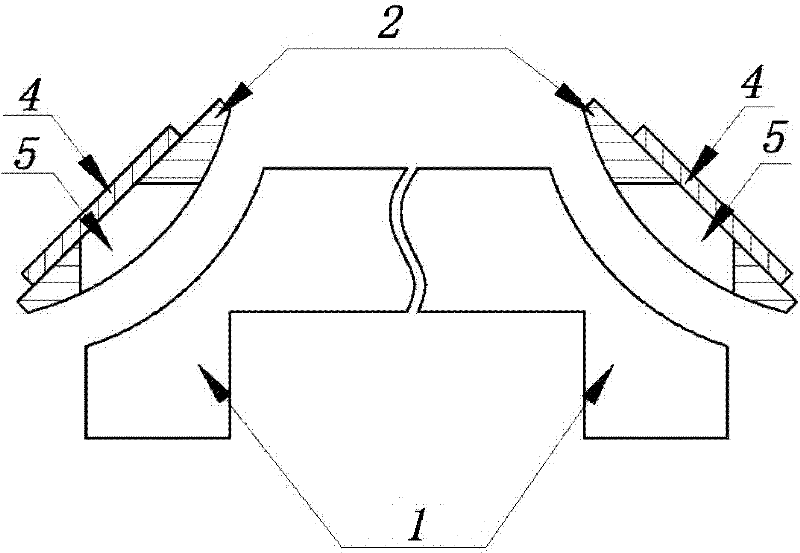

[0018] like image 3 As shown, the present embodiment is used for a folded CO2 laser tube, including a tube body 1 of a folded CO2 laser tube, a lens 4, a spherical mirror seat 2, and an optical hole 5, and the two parts of the tube body 1 of a folded CO2 laser tube Two ports are ground into a spherical surface, the radius of the spherical surface is the same as that of the spherical mirror base, and the concave and convex are opposite. The spherical mirror base 2 is bonded to the lens 4, and then bonded to the tube body 1 together. Adjust the angles of the two spherical mirror bases arbitrarily, so that the folding CO2 The two axis lines of the laser tube are on the same straight line through the two lenses. Since the spherical contact can be adjusted at any angle, the difficulty of manual grinding is greatly reduced, and the consistency of production efficiency is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com