Follow-up tracking material-supporting device

A technology of follow-up tracking and supporting materials, which is applied in the field of follow-up tracking and supporting devices, which can solve the problems of time-consuming and labor-intensive use, unsatisfactory use effects, and the inability to realize automatic follow-up, etc., and achieve the effect of improving accuracy and efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

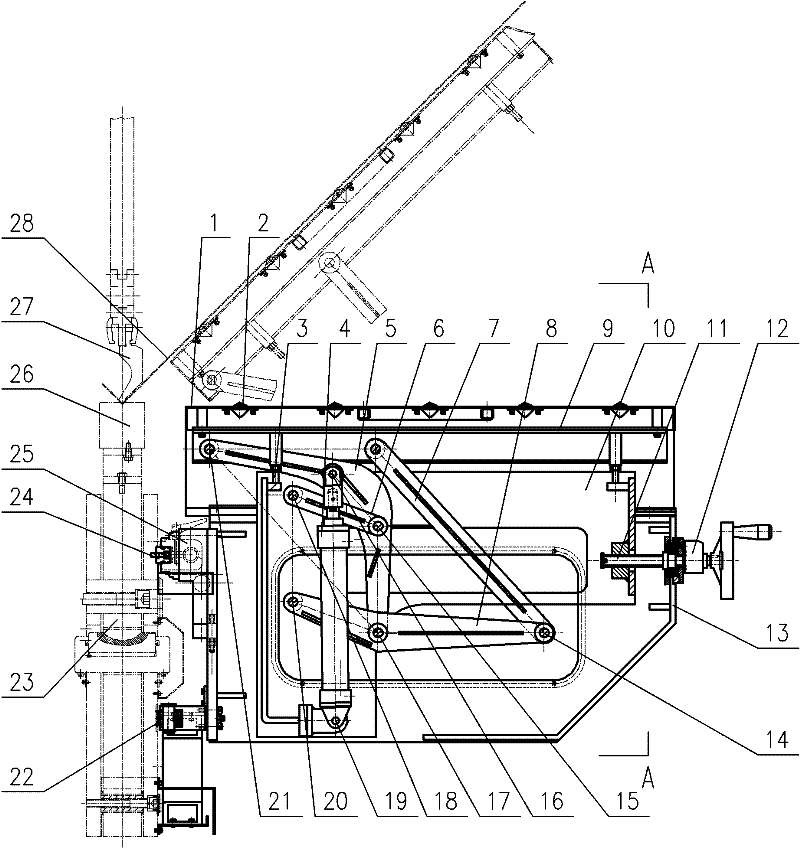

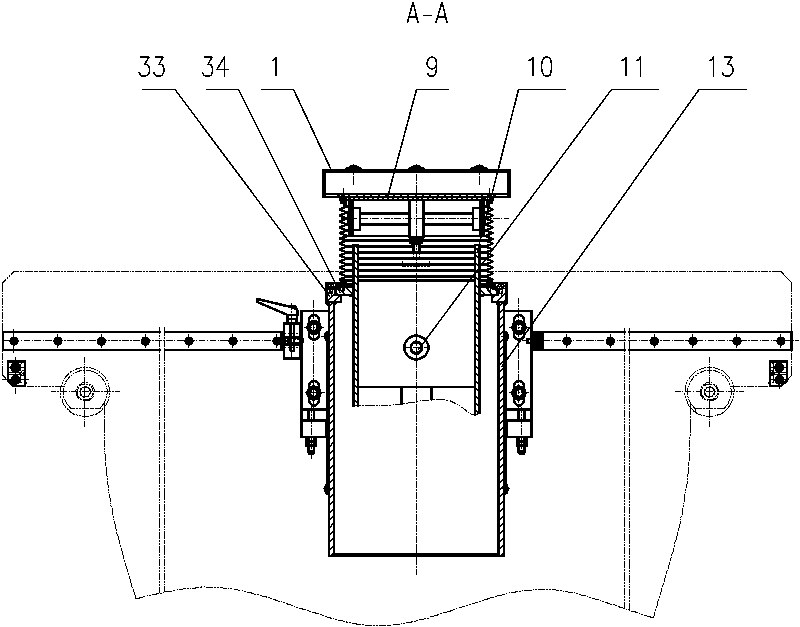

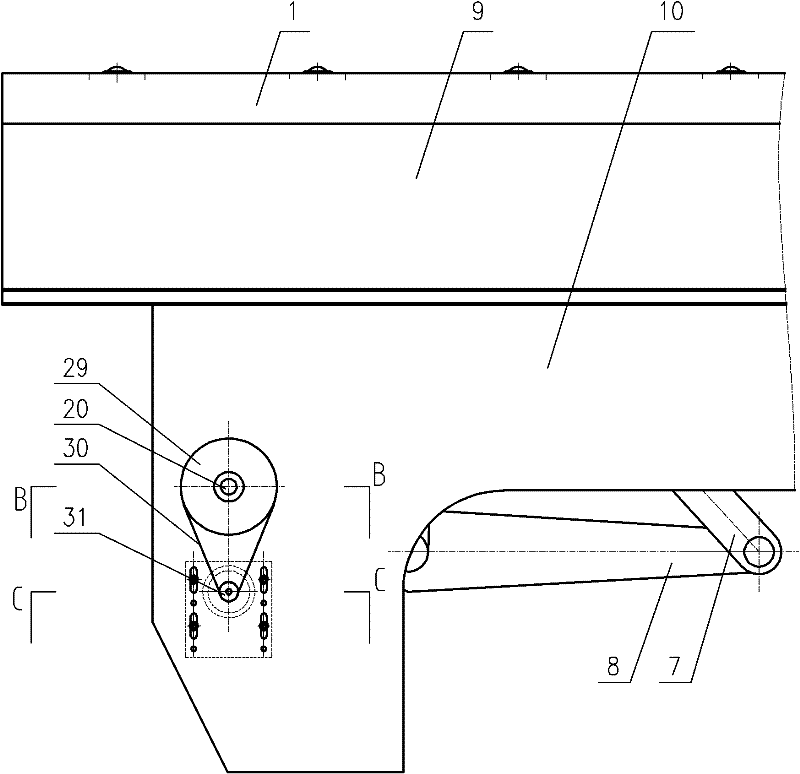

[0022] Figure 1 to Figure 5 Among them, including table panel 1, universal ball 2, limit screw 3, driving cylinder 4, four-point connecting rod 5, two-point connecting rod 6, long connecting rod 7, three-point connecting rod 8, turning body 9, Moving body 10, rotating lead screw 11, position indicator 12, fuselage 13, middle rod rotating hinge 14, inner hinge 15, oil cylinder driving hinge 16, lower hinge 17, upper connecting frame hinge 18, oil cylinder support hinge 19, lower connecting Frame hinge 20, flip hinge 21, moving roller 22, bending machine table 23, rolling linear guide rail 24, moving locking device 25, lower mold 26, upper mold 27, workpiece 28, large synchronous pulley 29, synchronous belt 30 , Small synchronous pulley 31, potentiometer 32, chute 33, slide rail 34 etc.

[0023] Such as figure 1 , figure 2 As shown, the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com