Insert reinforced nylon pipe pliers and manufacturing method

A manufacturing method and nylon tube technology, applied in the direction of manufacturing tools, wrenches, wrenches, etc., can solve the problems of unfavorable cold weather operation, high production cost, nylon collapse, etc., to increase comfort and security, low cost, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

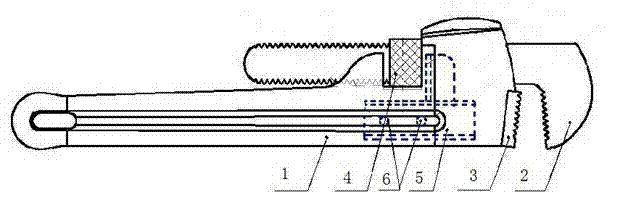

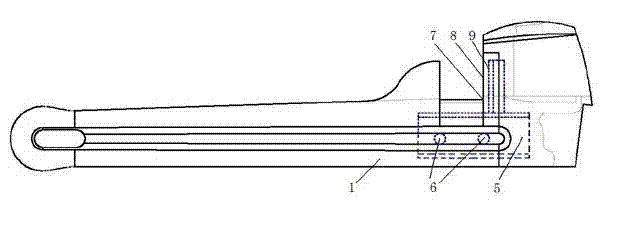

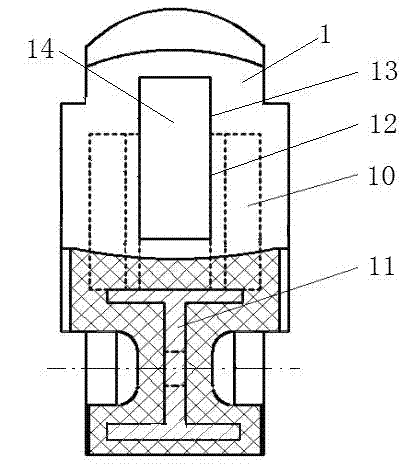

[0030] combine figure 1 and figure 2 , insert-reinforced nylon pipe wrench is composed of movable jaws, fixed jaws, adjusting nuts, pliers handle body, etc. The pliers handle body is composed of glass fiber reinforced polyamide 66 (nylon) and inserts embedded in it, inserts 5 It is a symmetrical structure, composed of a whole or two parts, in an "L" shape, with a "U" shape on the top and an "I" shape on the bottom. combine Figure 4 , Figure 8 , The insert 5 can adopt the insert A51, or the insert B52, or the insert C53 structure, to strengthen the stress concentration section 7 of the pipe wrench, or to increase the rigidity and strength of the nylon pliers handle.

[0031] combine Figure 8 , an insert or an insert B52 with a split structure, which consists of two parts: a component 521 and an I-shaped steel insert 522; the insert B52 is a symmetrical structure, and the component 521 is an "L" shape, and the upper "U" shape , the bottom is an inverted "concave" struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com