Tableware containing bamboo fibers and making method thereof

A technology of bamboo fiber and tableware, applied in the field of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

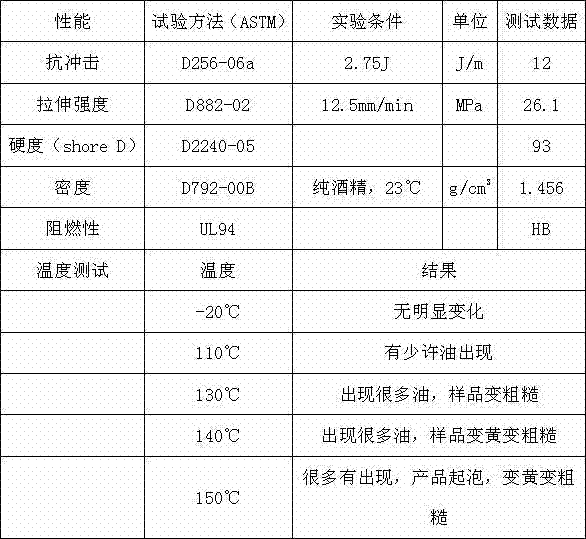

Image

Examples

Embodiment 1

[0027] After fully mixing the raw materials in Table 1, hot press molding at a temperature of 145°C and a pressure of 200t to obtain a semi-finished product with a certain shape, and perform surface cleaning treatment on the semi-finished product: wash the surface of the semi-finished product with water, and dry the surface of the semi-finished product to be cleaned. Spray a layer of transparent protective film with a thickness of 0.04mm on the outer surface of the semi-finished product, and then bake it at 100°C for 30 minutes. The protective film is polyester resin containing 0.5% (weight) matting agent. The particle size of the bamboo fiber is 60 mesh, and the particle size of the starch is 2000 mesh. The polyester resin in the present invention is a non-toxic and harmless resin that meets food-grade safety. For the convenience of description, the following examples all take acrylic resin as an example.

[0028] Table 1

[0029] Example Raw material / kg 1 2 3 ...

Embodiment 2

[0031] After fully mixing the raw materials in Table 1, hot press molding at a temperature of 160°C and a pressure of 300t to obtain a semi-finished product with a certain shape. Clean the surface of the semi-finished product: clean the surface of the semi-finished product with alcohol, and dry the surface of the semi-finished product to be cleaned. , spray a layer of transparent protective film with a thickness of 0.06mm on the outer surface of the semi-finished product, and then bake it at 120°C for 50 minutes. The protective film is an acrylic resin containing 0.6% by weight of a matting agent. The particle size of the bamboo fiber is 80 mesh, and the particle size of the starch is 1500 mesh.

Embodiment 3

[0033] After fully mixing the raw materials in Table 1, hot press molding at a temperature of 150°C and a pressure of 250t to obtain a semi-finished product with a certain shape, and perform surface cleaning treatment on the semi-finished product: wash the surface of the semi-finished product with water, and dry the surface of the semi-finished product to be cleaned. Spray a layer of transparent protective film with a thickness of 0.06mm on the outer surface of the semi-finished product, and then bake it at 100°C for 30-50 minutes. Protective film is acrylic resin with 1% by weight matting agent. The particle size of the bamboo fiber is 60-80 mesh, and the particle size of the starch is 1800 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com