Flower and leaf drying box

A technology for drying boxes and flowers, applied in the direction of drying, drying machines, non-progressive drying machines, etc., which can solve the problems of not being easy to move, wasting energy, etc., and achieve the effects of easy operation, energy saving, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

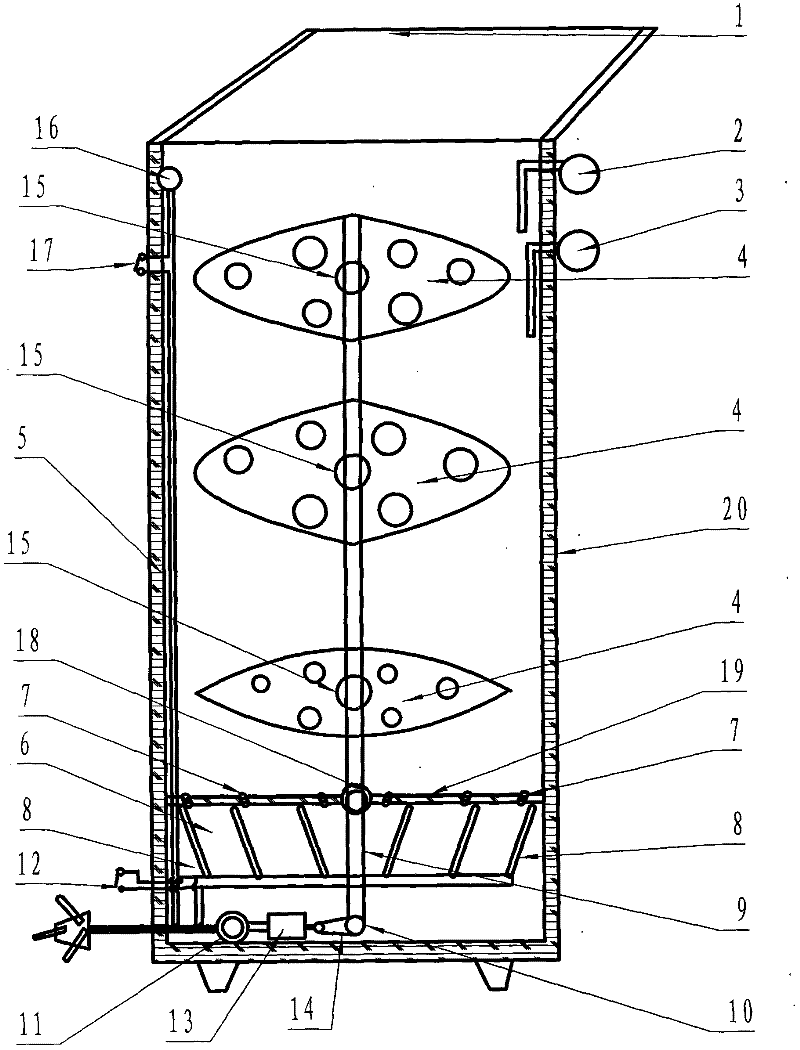

[0011] Embodiment 1, a drying box for flowers and leaves, including two sides and the back of the stainless steel frame inlaid with glass, and a drying box body 20 with a handle glass door in the front, characterized in that: the drying box The main body 20 is equipped with a cold and hot air exchange hole 7, a partition 19 with a bearing 18 in the middle, and consists of a drying chamber 5 and a heating power chamber 6.

[0012] The top of the drying chamber 5 is equipped with a solar thermal collector plate 1, and the rotating shaft 9 with the tray 15 inside is set in the bearing 18 of the partition 19, and the circular grid plate 4 is installed on the rotating shaft 9 On the tray 15, the top of the right side panel is equipped with a thermometer 2 and a dry humidity meter 3, and the top of the left side panel is equipped with an exhaust fan 16 with an exhaust fan switch 17.

[0013] The top in the heating power chamber 6 is equipped with 10 electric heating tubes 8 with ele...

Embodiment 2

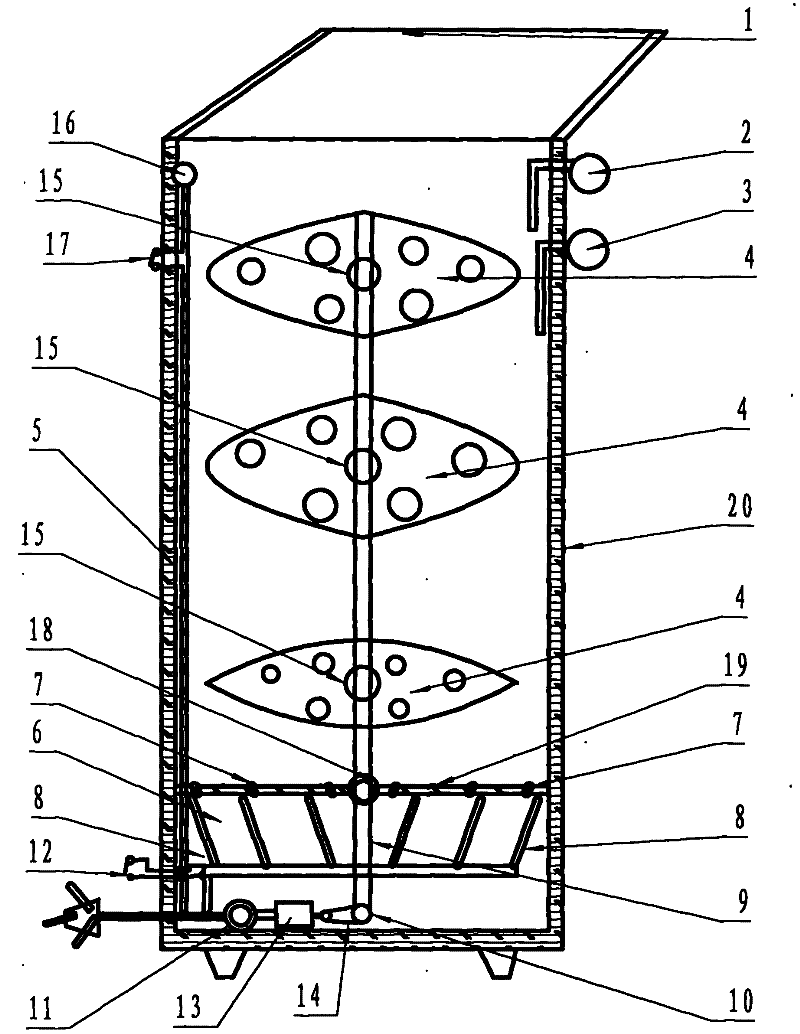

[0014] Embodiment 2, a drying box for flowers and leaves, including a stainless steel frame with glass inlaid on the two sides and the back, and a drying box body 20 with a handle glass door in front, characterized in that: the drying box The main body 20 is equipped with a cold and hot air exchange hole 7, a partition 19 with a bearing 18 in the middle, and consists of a drying chamber 5 and a heating power chamber 6.

[0015] The top of the drying chamber 5 is equipped with a solar thermal collector plate 1, and the rotating shaft 9 with the tray 15 inside is set in the bearing 18 of the partition 19, and the circular grid plate 4 is installed on the rotating shaft 9 On the tray 15, the top of the right side panel is equipped with a thermometer 2 and a dry humidity meter 3, and the top of the left side panel is equipped with an exhaust fan 16 with an exhaust fan switch 17.

[0016] 12 electric heating tubes 8 with electric heating tube switches 12 are installed in the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com