Split extruded and spliced water-cooled motor shell

A water-cooled motor and splicing technology, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of complicated welding process at the extrusion end, easy cracks at the welding place, and inconvenient transportation. Achieve the effect of simple and reliable assembly, simple mold and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

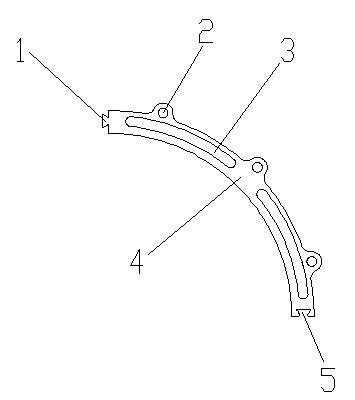

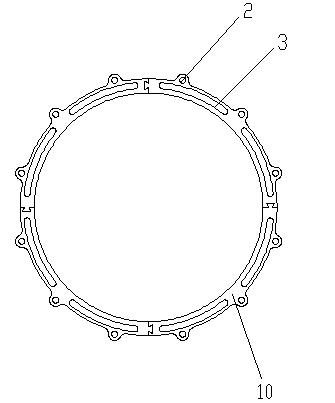

[0025] see figure 1 , image 3 with Figure 5 , splicing the connector 1 on one split piece 4 with the connecting groove 5 on the other split piece 4, several split pieces 4 are finally spliced into a shell 10, and bolts are passed through the bolts on the split piece 4 The hole 2 connects the housing 10 with the front end cover 11 and the rear end cover 14, the inner ring of the stator 9 and the housing 10 is an interference fit, and the two ends of the water guide hole 3 are equipped with gaskets 13 to prevent the cooling water from overflowing. Cooling water enters the water guide hole 3 through the water inlet 15, flows into the next water guide hole 3 through the end cover groove 12, flows back and forth in the interlayer of the housing 10, and finally flows out from the water outlet 16 (see Image 6 ), and take away the heat generated by the motor.

Embodiment 2

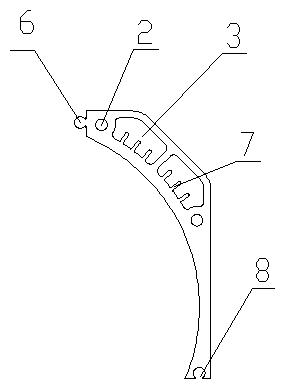

[0027] see figure 2 , Figure 4 with Figure 5 , splicing the connecting head 6 on one split piece 4 with the connecting groove 8 on the other split piece 4, several split pieces 4 are finally spliced into a shell 10, and bolts are passed through the bolts on the split piece 4 The hole 2 connects the housing 10 with the front end cover 11 and the rear end cover 14, the inner ring of the stator 9 and the housing 10 is an interference fit, and the two ends of the water guide hole 3 are equipped with gaskets 13 to prevent the cooling water from overflowing. Cooling water enters the water guide hole 3 through the water inlet 15, flows into the next water guide hole 3 through the end cover groove 12, flows back and forth in the interlayer of the housing 10, and finally flows out from the water outlet 16 (see Image 6 ), and take away the heat generated by the motor through the fins 7 on the water guide hole 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com