Cobalt-nickel superalloys, and related articles

A technology of cobalt-nickel alloy and alloy, which is applied in the field of cobalt-nickel alloy and can solve problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] The examples provided below are illustrative only and should not be construed as any limitation on the scope of the claimed invention.

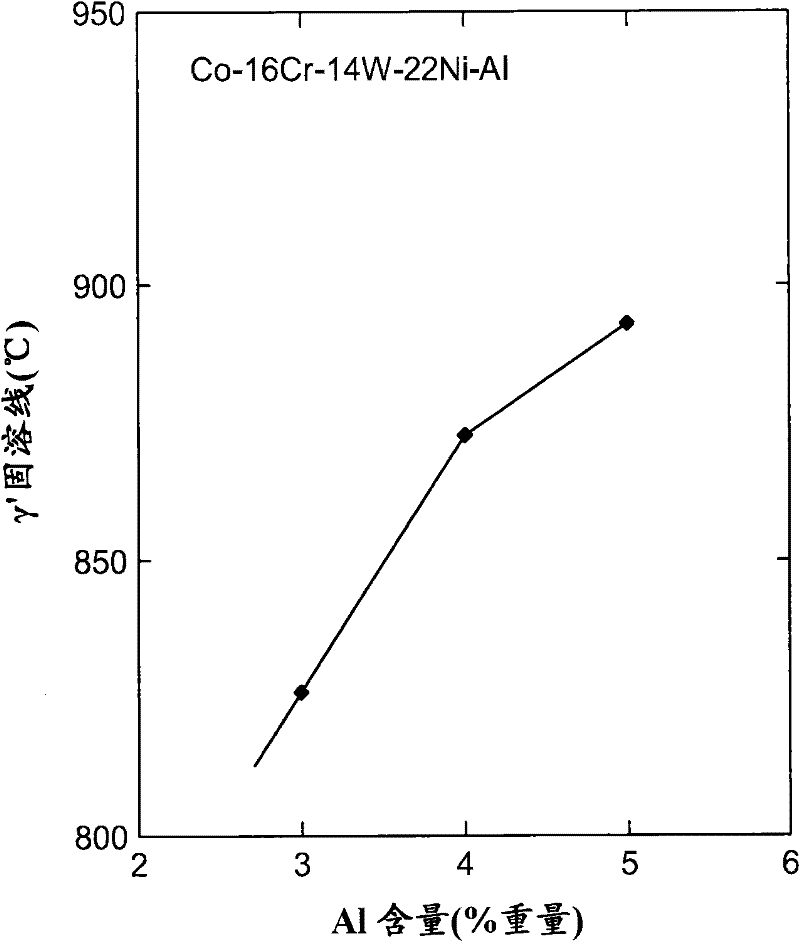

[0078] The alloy composition was chosen based on the conventional cobalt-based alloy Haynes 188 consisting essentially of Co-22%Cr-22%Ni-14%W-3%Fe-0.1%C. 2-5 wt% Al was added to Co-22%Cr-22%Ni-14%W and Co-16%Cr-22%Ni-14%W. In addition, 1-2% by weight of Ta is added to Co-22%Cr-22%Ni-14%W-4%Al and Co-16%Cr-22%Ni-14%W-4%Al. The addition of 4% Al makes an alloy with a high Ni content.

[0079] Table 1 Composition

[0080]

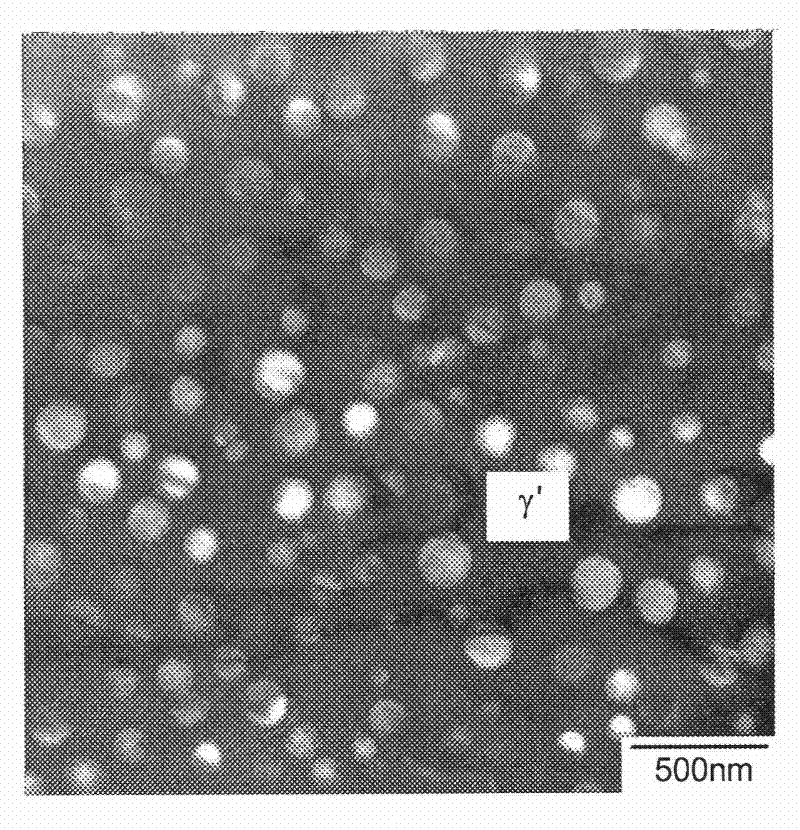

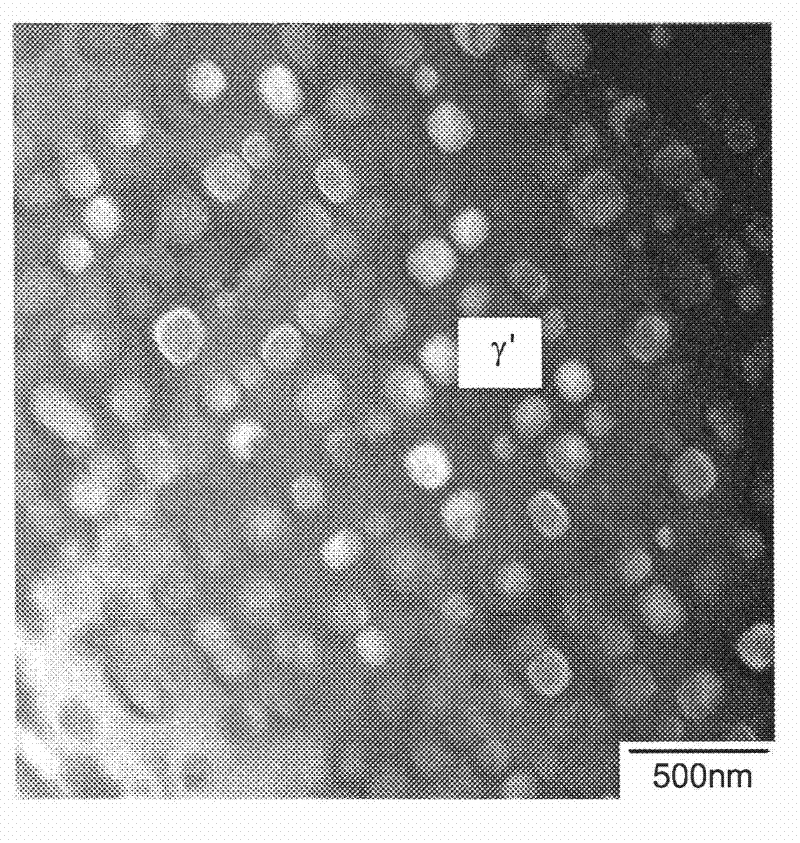

[0081] One pound ingots of each alloy were prepared by induction melting. The alloy was solution treated at 1200°C for 6 hours, followed by air cooling. Two pieces cut from each alloy were aged at 900° C. and 1000° C. for 100 hours, respectively. Aging is done by air cooling. Transmission electron microscopy and scanning electron microscopy were performed to examine γ′-(Co,Ni) 3 (Al,W) phase exists. Differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com