Windmill wind blade with multiple blades on outer ring

A technology of windmills and outer rings, applied to wind engines at right angles to the wind direction, wind engines, greenhouse gas reduction, etc., can solve problems such as low efficiency, poor aerodynamics, and small wind-receiving area of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

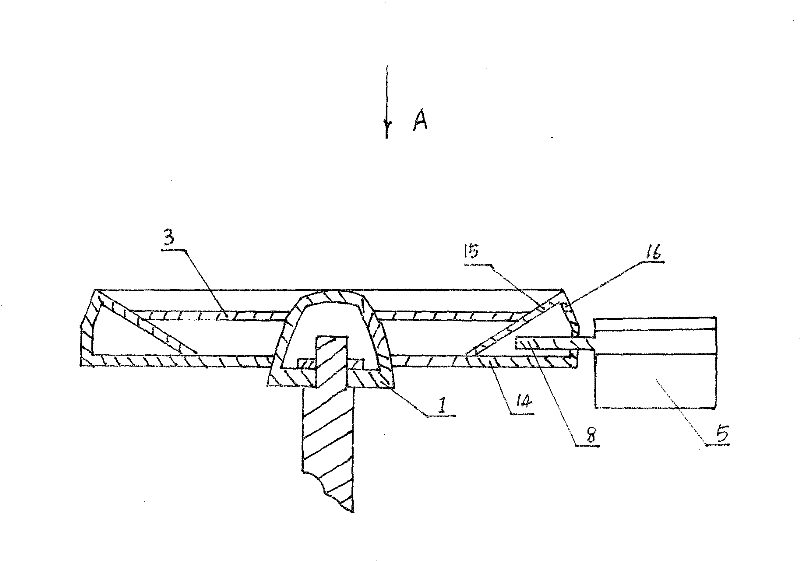

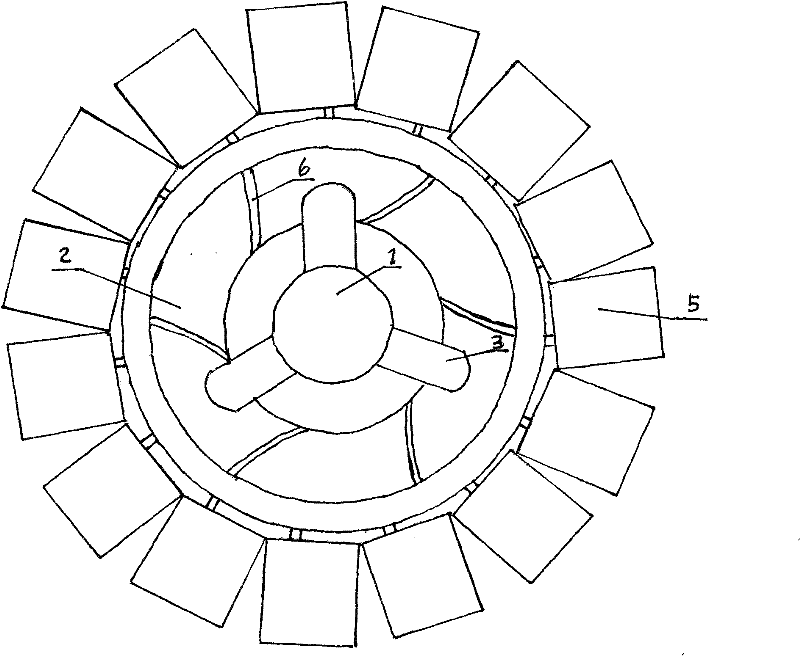

[0013] figure 1 It is a schematic structural diagram of the present invention, figure 2 It is a schematic structural diagram of the present invention (from figure 1 Middle A looks), the present invention is made up of windmill hub 1, radial skeleton pipe 3, annular skeleton ring 2 and the main and auxiliary blades 5 and 6 groups of the inner and outer circles of annular skeleton circle, and radial skeleton pipe 3 is used for The windmill hub 1 is connected with the ring-shaped skeleton ring 2, and the ring-shaped skeleton ring 2 has a ring structure.

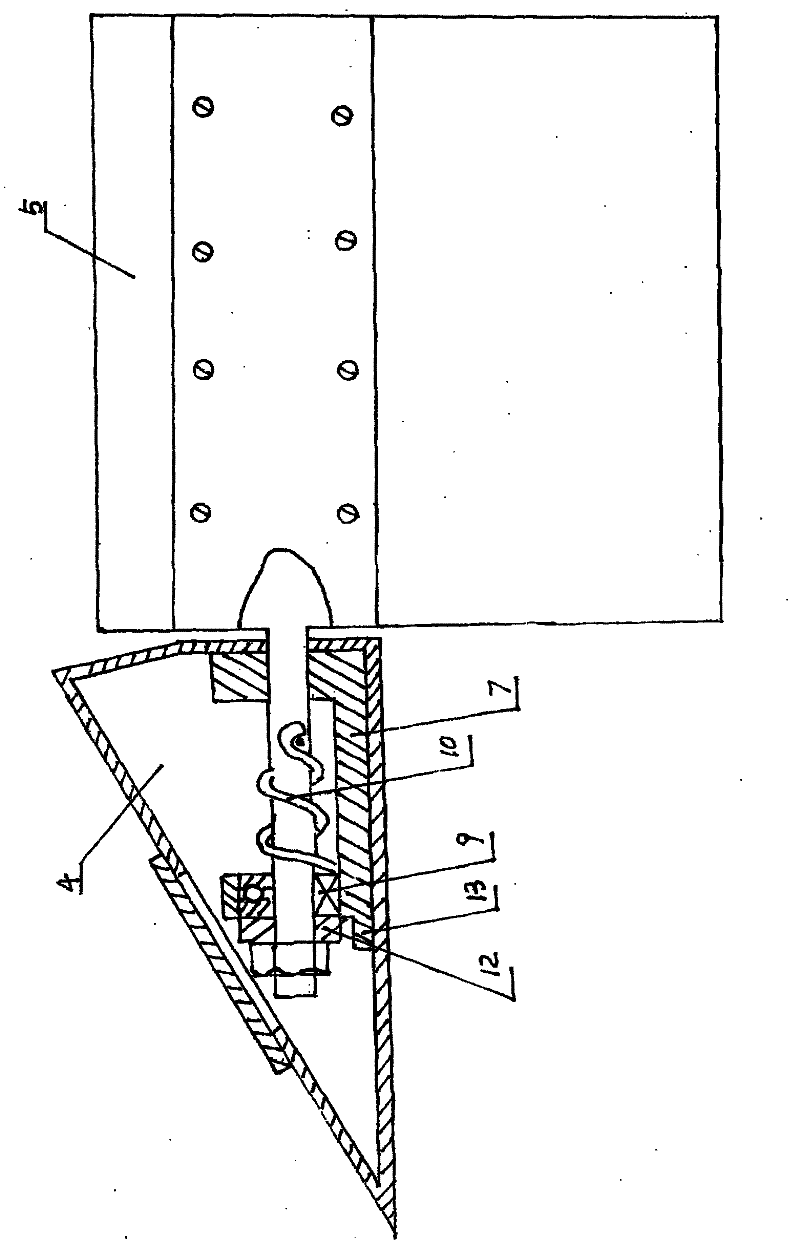

[0014] The interior of the annular skeleton ring 2 is set as a cavity 4, and the cut surface of the cavity 4 is a quadrilateral, wherein the angle between the bottom side 14 and the long hypotenuse 15 is 25°-30°, and the angle between the long hypotenuse 15 and the upper short hypotenuse 16 is 70° °~75°, the cavity 4 is provided with a blade shaft seat 7, a thrust bearing 9, a torsion spring 10, a chuck 13, a chuck 12, etc. t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com