Inert gas short arc discharge lamp

A short-arc discharge lamp and inert gas technology, which is applied to parts of gas discharge lamps, high-pressure discharge lamps, etc., can solve problems such as changes in the ignition characteristics of discharge lamps, and achieve the effect of increasing working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

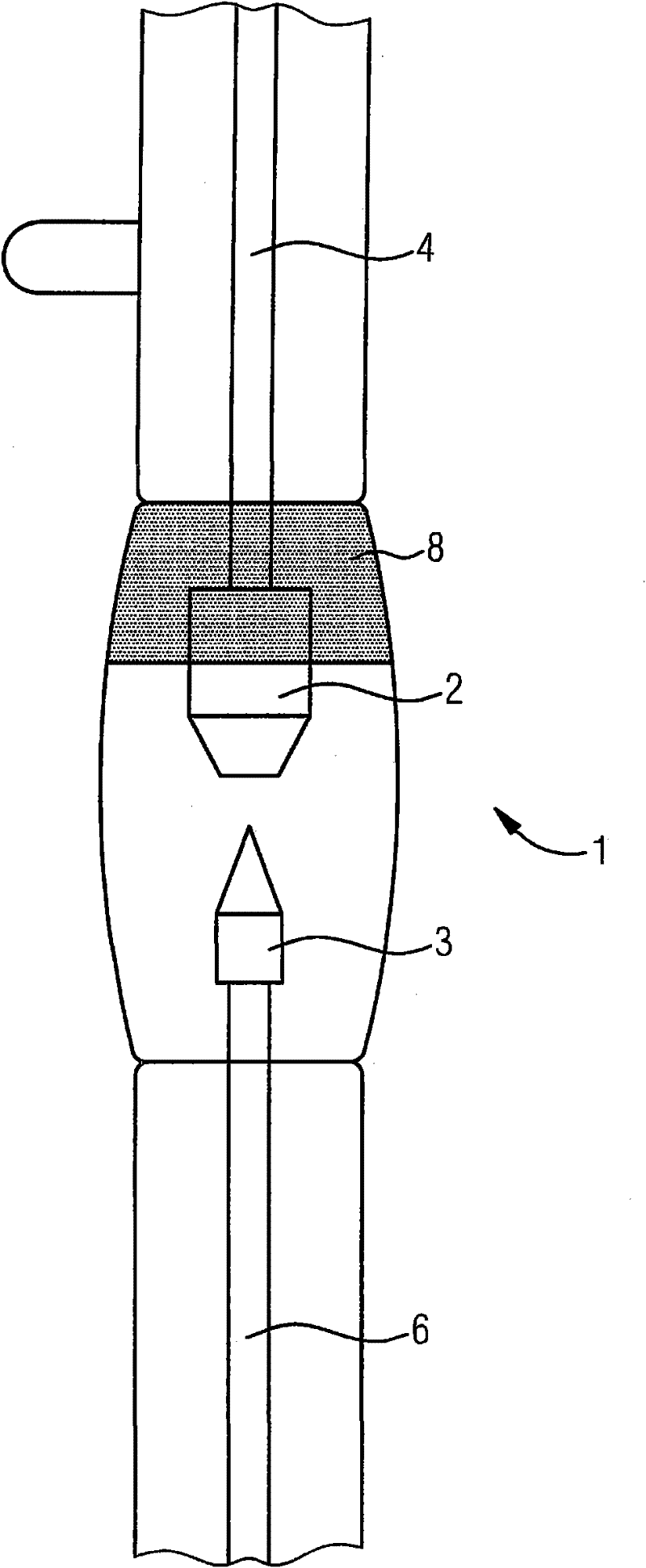

[0022] figure 1 A view shows a section through an exemplary embodiment of a noble gas short-arc discharge lamp designed for direct current operation (DC) with a power consumption of 450 W. The lamp has a discharge vessel 1 made of glass, in which an anode 2 and a cathode 3 are arranged at a distance from one another. The two electrodes 2 , 3 are held in the discharge vessel 1 by corresponding electrode rods 4 , 6 . For its part, the electrode rods are arranged in the corresponding end regions of the lamp or are guided out in a gas-tight manner in order to be able to be connected to an external power supply (not shown). The discharge vessel 1 is filled with pure xenon at a cold filling pressure of 10 bar. This corresponds to the cold fill pressure of a conventional 450W short-arc xenon lamp.

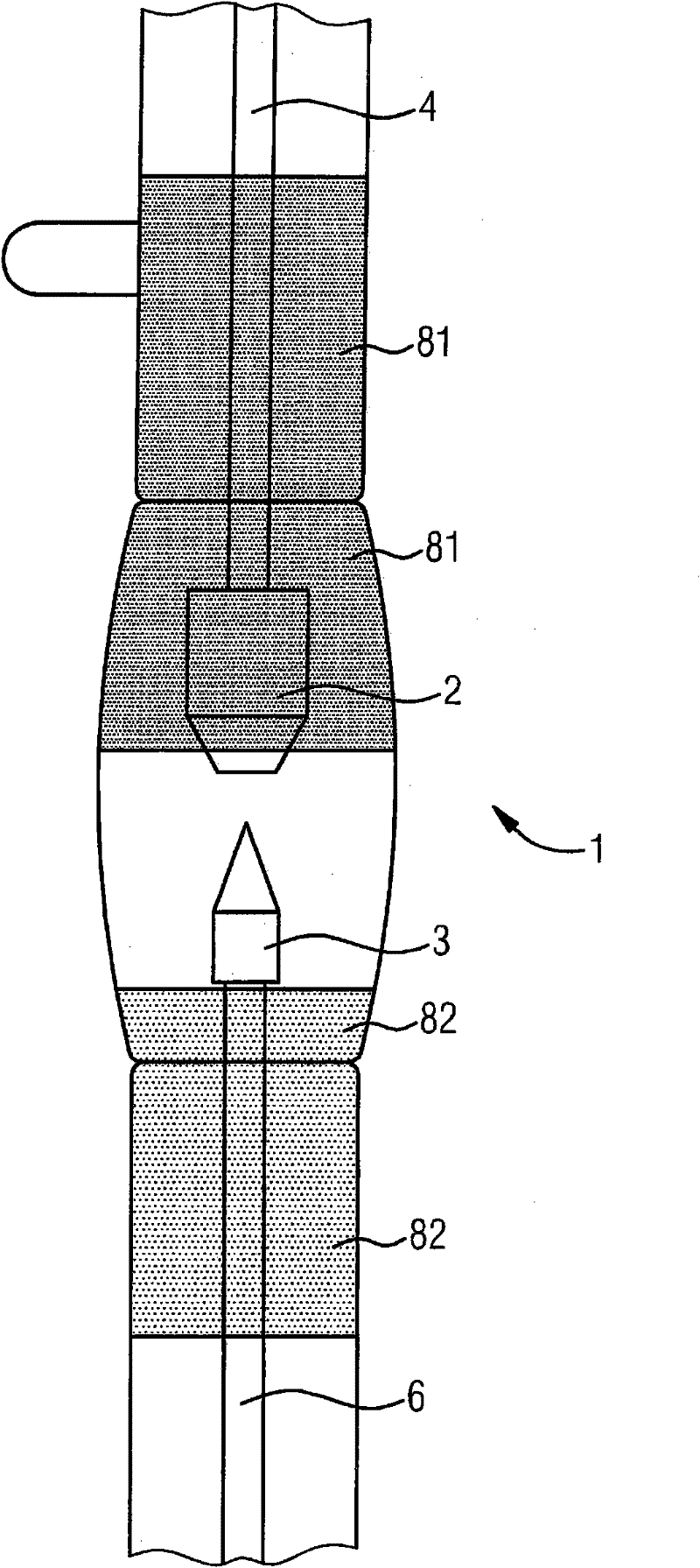

[0023] In the region of the anode 2 , the outer side of the discharge vessel 1 is provided with a coating 8 . Here, the coating 8 alternately consists of silicon dioxide (SiO 2 ) lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com