Idle stroke-free punching machine

A stamping machine and idle stroke technology, which is applied in the field of no empty stroke stamping machine, can solve the problems of low work efficiency and large equipment investment, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

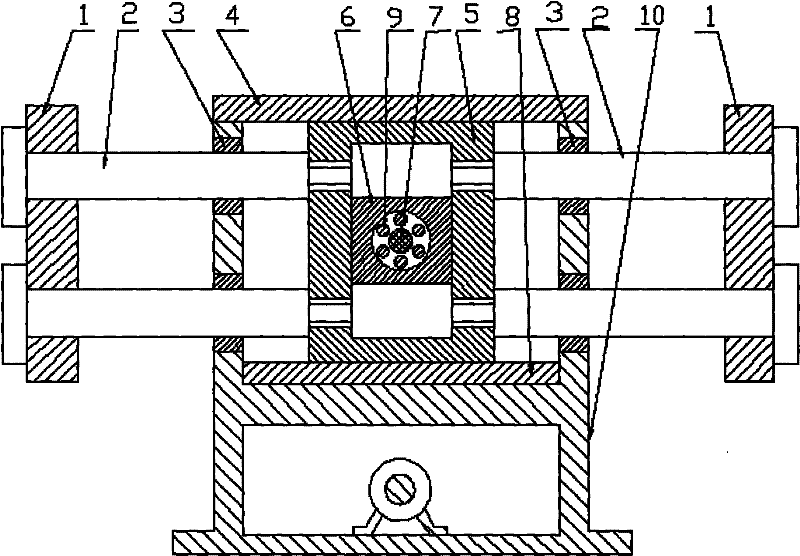

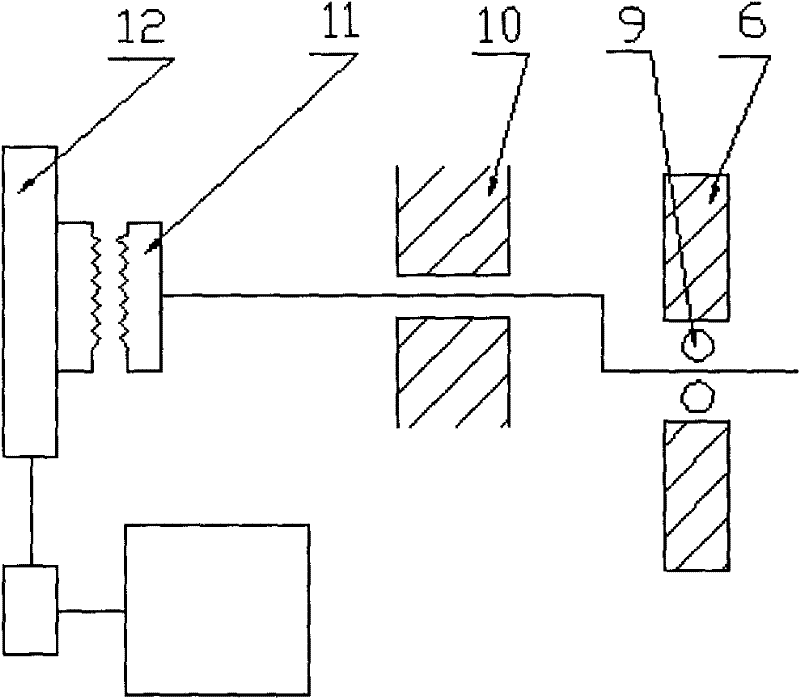

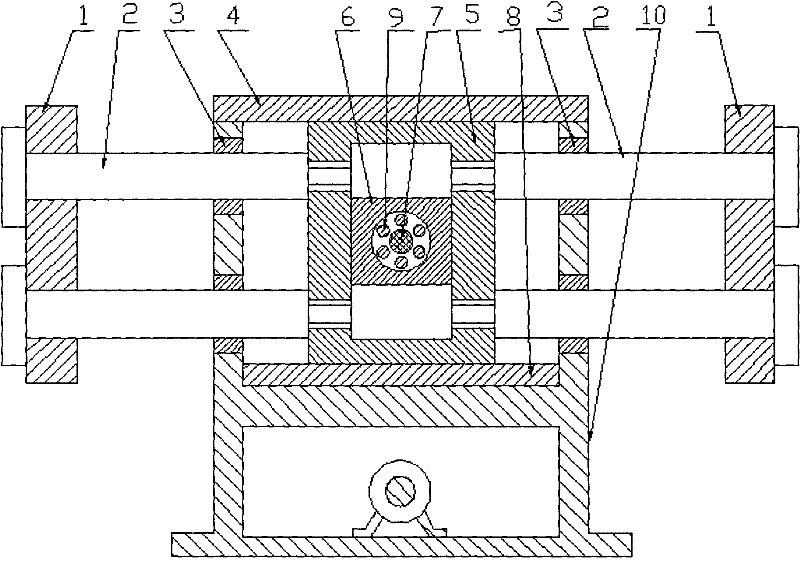

[0011] Install and fix the lower guide rail plate (8) at the ㄩ-shaped inner opening on the top of the fuselage (10), install the square sleeve (5) in the ㄩ-shaped opening on the lower guide rail plate (8), and pass the upper guide rail plate (4) through The bolts are installed and fixed on the upper opening of the ㄩ-shaped opening to ensure that the upper guide rail plate (4) and the lower guide rail plate (8) engage the square sleeve (5) in the ㄩ-shaped opening, so that the square sleeve (5) can only move left and right freely and ensure that the square sleeve (5) moves in the specified direction, install and fix the sliding bearing (3) on both sides of the ㄩ-shaped opening on the fuselage (10), and pass the guide rod (2) through the sliding bearing (3) Connect and fix the square sleeve (5), install and fix the slider (1) on the top of the guide rod (2), and install the square sleeve slider (6) at the mouth of the square sleeve (5) to ensure that the square sleeve slides The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap