Wall panel skin shape drilling die and manufacturing method thereof

A technology of shape and jig, which is applied in the direction of the jig for the workpiece, can solve the problems of high manufacturing cost, limited scope of application, complex structural design, etc., and achieve high fit, universal applicability, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

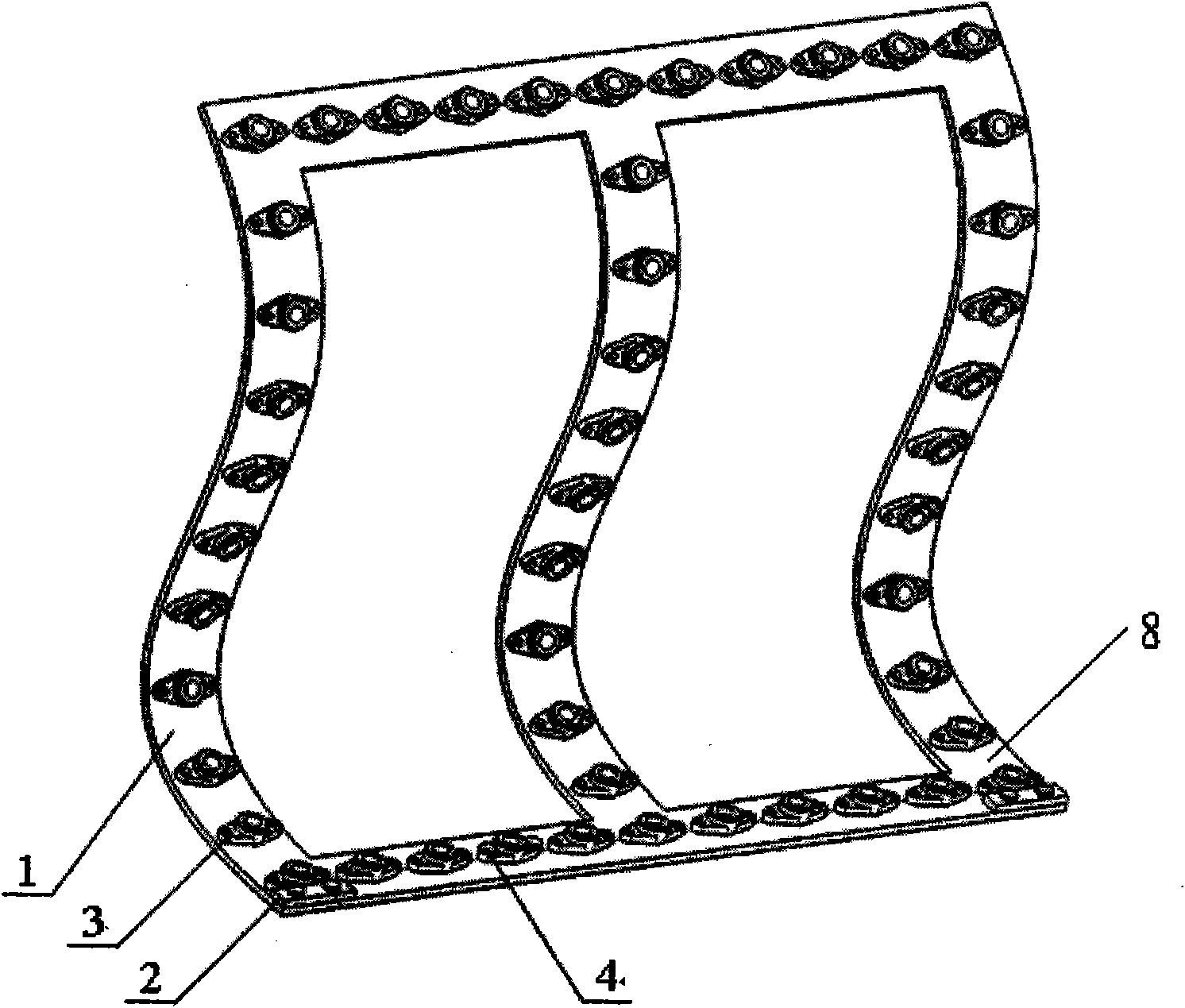

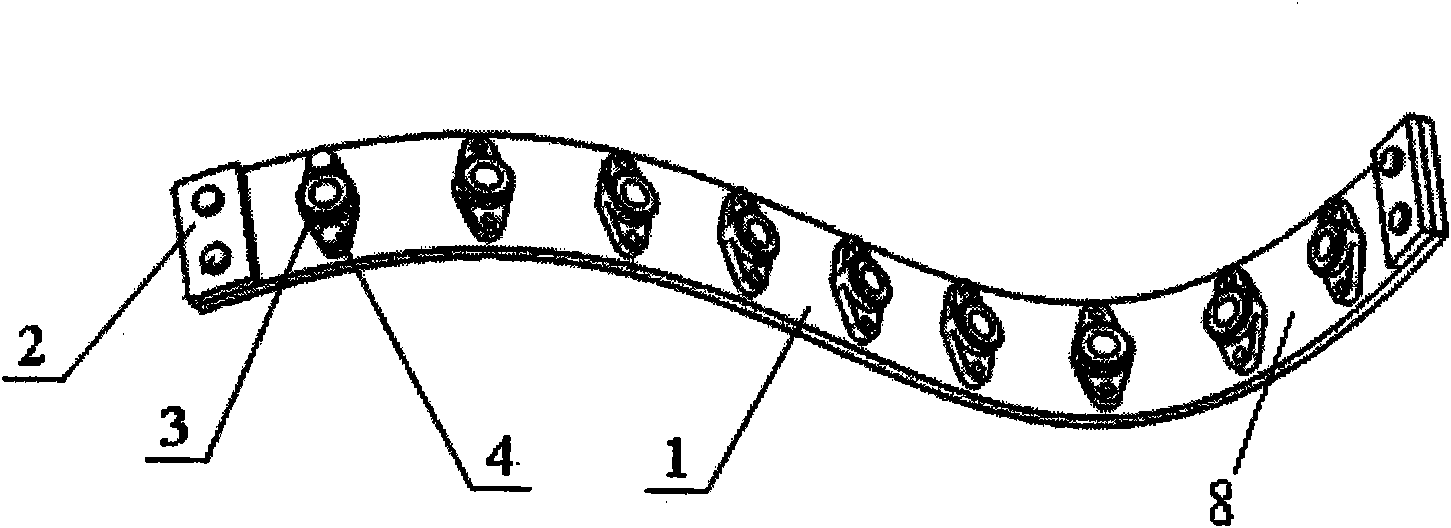

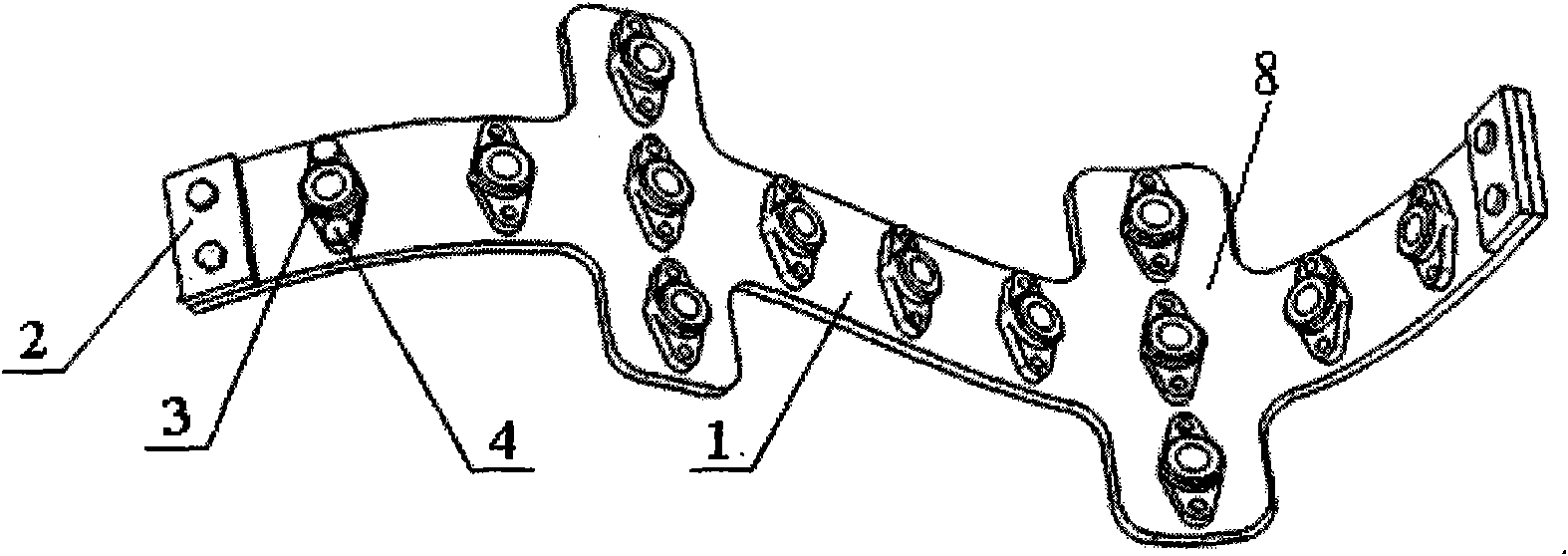

[0019] Referring to the accompanying drawings, the wall panel skin shape drilling template structure is mainly composed of shape thin plate 1, reference edge strip 2 and drill sleeve 3. The drilling mold structure of the outer skin of the wall panel must be made according to the distribution of the drilling holes of the digital model of the outer wall panel and the skin forming mold. The skin is equal to the thickness of the cushion to form a shape thin plate 1 with the same curvature as the wall panel skin 5, and the drilling mold bottom hole 6 is made according to the actual drilling distribution position on the shape digital model of the wall panel skin, and then the drilling mold The drill bushing 3 is installed at the bottom hole, and the center hole 7 of the drill bushing 3 is required to be coaxial with the bottom hole 6 of the drilling mold, such as Figure 4 shown.

[0020] The drill bushing 3 is preferably a double-lug stepped bushing, or a single-lug stepped bushin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com