Preparation method of visible light catalyst

A catalyst, visible light technology, applied in the field of chemistry, can solve problems such as unfavorable environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a preparation method of a visible light catalyst, comprising the following steps:

[0032] Calcining urea at 300-700°C to obtain C 3 N 4 .

[0033] The calcination described in the present invention can be carried out under aerobic or anaerobic conditions, wherein, the calcination temperature is the preparation C of the present invention. 3 N 4 The key, the temperature is too high or too low can not get C 3 N 4 , the calcination temperature is preferably 400-600°C, more preferably 500-600°C, most preferably 550°C. At the same time, the calcination time is also in the preparation of C 3 N 4 An important condition in the process, the calcination time is preferably 0.1-10 h, more preferably 1-5 h, most preferably 2 h.

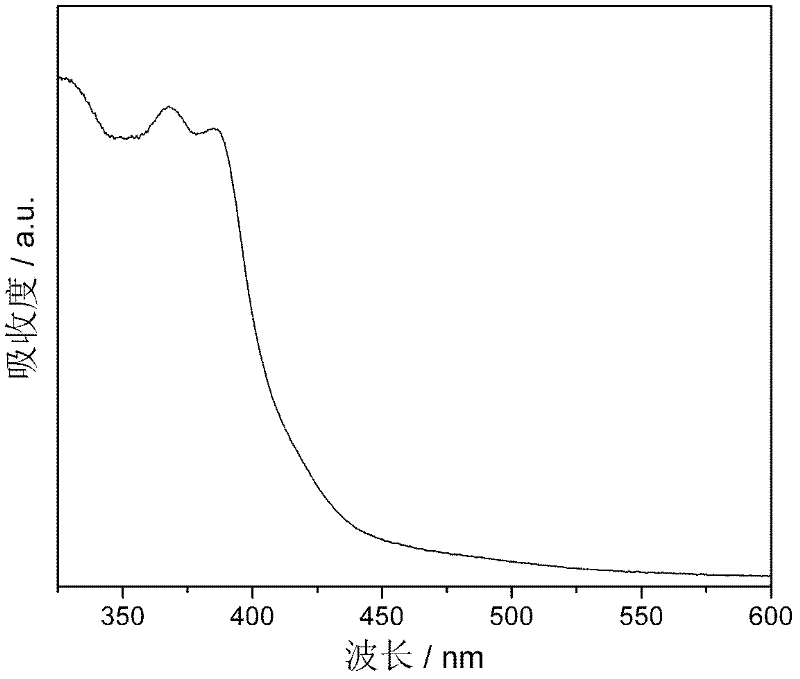

[0034] C prepared by the present invention 3 N 4 It has a layered structure and a forbidden band width of 2.7eV, which can greatly absorb visible light. Its absorption wavelength is red-shifted to 600nm, and it has visible ...

Embodiment 1

[0050] Weigh 10.0g of urea and place it in a crucible, calcining under aerobic conditions, the calcining temperature is 550°C, the calcining time is 2h, and cooling to obtain C 3 N 4 catalyst.

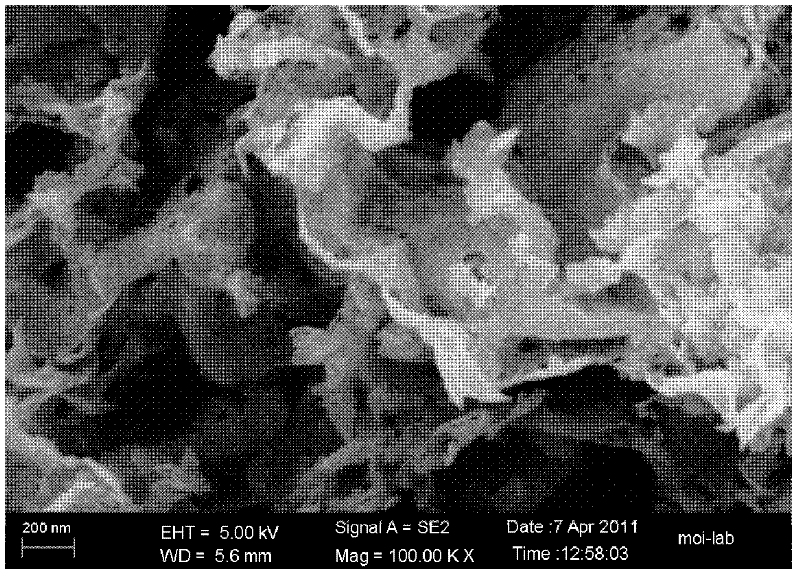

[0051] Such as figure 1 Shown, the C prepared for the implementation of the present invention 3 N 4 The SEM picture.

Embodiment 2

[0053] Weigh 10.0g of urea and put it in a crucible, calcining under anaerobic conditions, the calcining temperature is 450°C, the calcining time is 4h, and cooling to obtain C 3 N 4 catalyst.

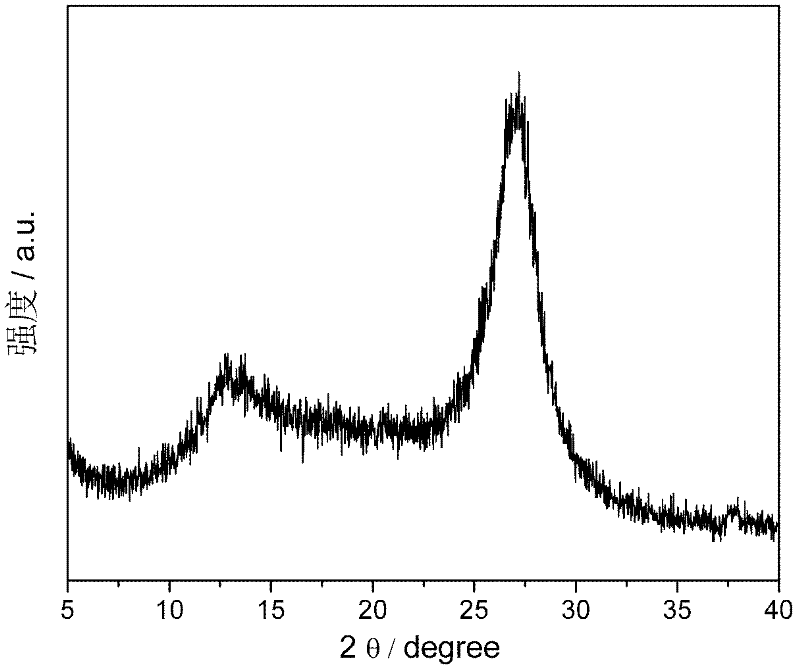

[0054] Such as figure 2 Shown, for the C prepared in this example 3 N 4 The XRD pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com