Liquid steel casting equipment

A liquid steel and liquid state technology, applied in the field of liquid steel pouring equipment, can solve the problems of microscopic defects, high manufacturing cost, long production cycle, etc., achieve the effects of improving the temperature field distribution, easy operation of the method, and reducing the phenomenon of slag entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

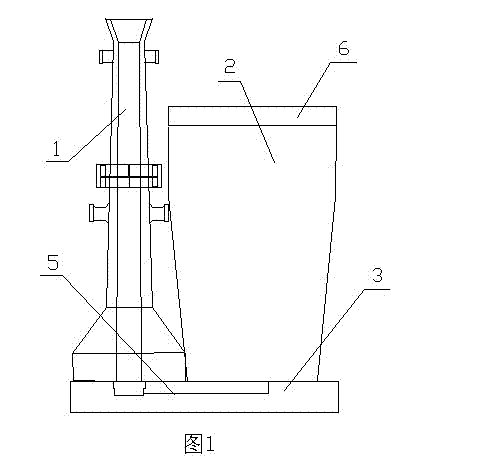

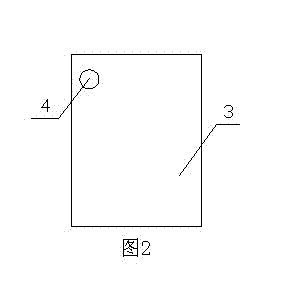

[0018] Such as figure 1 , figure 2 Shown: a liquid steel pouring equipment, including an ingot mold 2, the upper part of the ingot mold 2 is provided with a thermal insulation cap 6, the ingot mold 2 is arranged on the ingot mold chassis 3, and a flow steel channel is arranged in the ingot mold chassis 3 5. The flow steel channel 5 communicates with the center injection pipe 1 arranged on one side of the ingot mold 2, the flow steel channel 5 communicates with the pouring port 4 on the bottom of the ingot mold, and the bottom of the ingot mold 2 deviates from the ingot mold 2 A sprue 4 is arranged at the center of the bottom, near the bottom corner of the ingot mould. There are three ingot moulds, each of which can pour 33t of molten steel. The 280mm thick low-alloy Q345B steel plate that meets the F2 standard of forging flaw detection can be produced by using this equipment and a suitable process. At present, 18 ingots are produced, the thickness of the steel plate is 200...

Embodiment 2

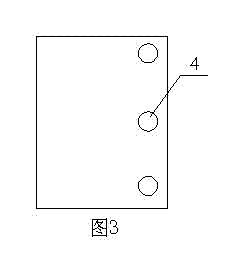

[0020] Such as figure 1 , image 3 Shown: a liquid steel pouring equipment, including an ingot mold 2, the upper part of the ingot mold 2 is provided with a thermal insulation cap 6, the ingot mold 2 is arranged on the ingot mold chassis 3, and a flow steel channel is arranged in the ingot mold chassis 3 5. The flow steel channel 5 communicates with the center injection pipe 1 arranged on one side of the ingot mold 2, and the flow steel channel 5 communicates with the three pouring ports 4 on the side of the ingot mold, and the pouring ports 4 deviate from the ingot mold 2 Bottom center position. The diameter of the center injection pipe is 80mm, and the diameter of the sprue is 60mm; there are two ingot moulds, each of which can pour 43t of molten steel. The 250mm thick low-alloy Q345D steel plate that meets the F2 standard of forging flaw detection can be produced by using this equipment and a suitable process. At present, 12 ingots are produced, the thickness of the stee...

Embodiment 3

[0022] Such as figure 1 , Figure 4 Shown: a liquid steel pouring equipment, including an ingot mold 2, the upper part of the ingot mold 2 is provided with a thermal insulation cap 6, the ingot mold 2 is arranged on the ingot mold chassis 3, and a flow steel channel is arranged in the ingot mold chassis 3 5. The flow steel channel 5 communicates with the center injection pipe 1 arranged on one side of the ingot mold 2, the flow steel channel 5 communicates with the pouring port 4 on the bottom of the ingot mold, and the bottom of the ingot mold 2 deviates from the ingot mold 2 A sprue 4 is arranged at the center position of the bottom, at 1 / 4 of the length (width) direction of the center line of the bottom of the ingot mould. The diameter of the middle injection pipe is 80mm, and the diameter of the sprue is 60mm; there are two ingot moulds, each of which can pour 48t of molten steel.

[0023] The 240mm thick low-alloy Q345B steel plate that meets the F2 standard of forging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com