Quantum dot-agarose composite microsphere and preparation method thereof

A technology of agarose gel microspheres and composite microspheres, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of insufficient chemical stability of quantum dot composite microspheres, low quantum dot concentration, quantum dot leakage and the like, Achieve the effect of facilitating promotion and application, stabilizing chemical properties, and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

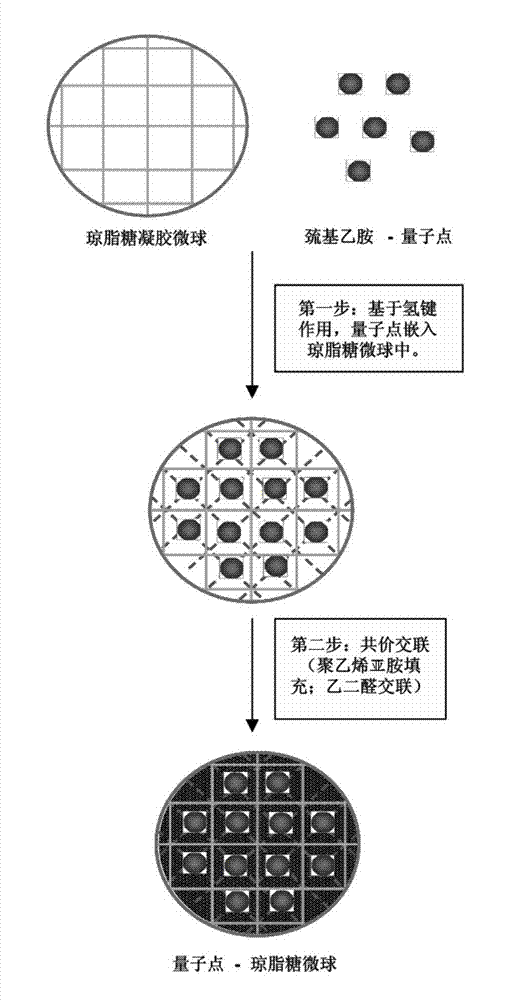

Embodiment 1

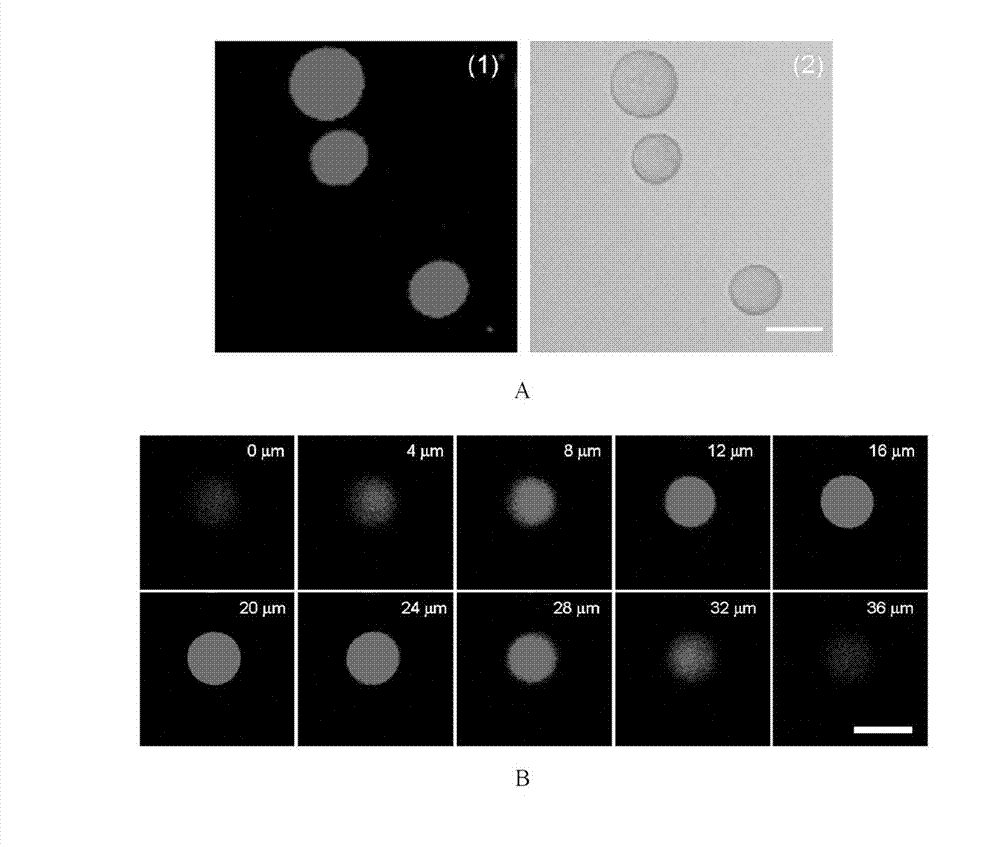

[0030] A quantum dot-agarose composite microsphere of the present invention, which uses honeycomb-shaped agarose gel microspheres (average particle diameter of 35 mm) as the matrix, and the pores of the matrix are filled with CdSe modified by mercaptoethylamine / ZnS quantum dots (that is, mercaptoethylamine-CdSe / ZnS quantum dots), a layer of polyethyleneimine is attached to the inner wall of the matrix pores, and the amine groups in polyethyleneimine are combined with mercaptoethylamine-CdSe / ZnS quantum dots through the aldehyde group The amine groups on the dots are cross-linked into one, and the average number of mercaptoethylamine-CdSe / ZnS quantum dot particles filled on a single agarose gel microsphere is 6.0×10 7 .

[0031] The quantum dot-agarose composite microspheres of this embodiment are specifically prepared through process steps:

[0032] (1) Preparation of mixed solution: Prepare 10 mL of fluorescence emission wavelength at 602 nm and concentration of 10 -6 M's ...

Embodiment 2

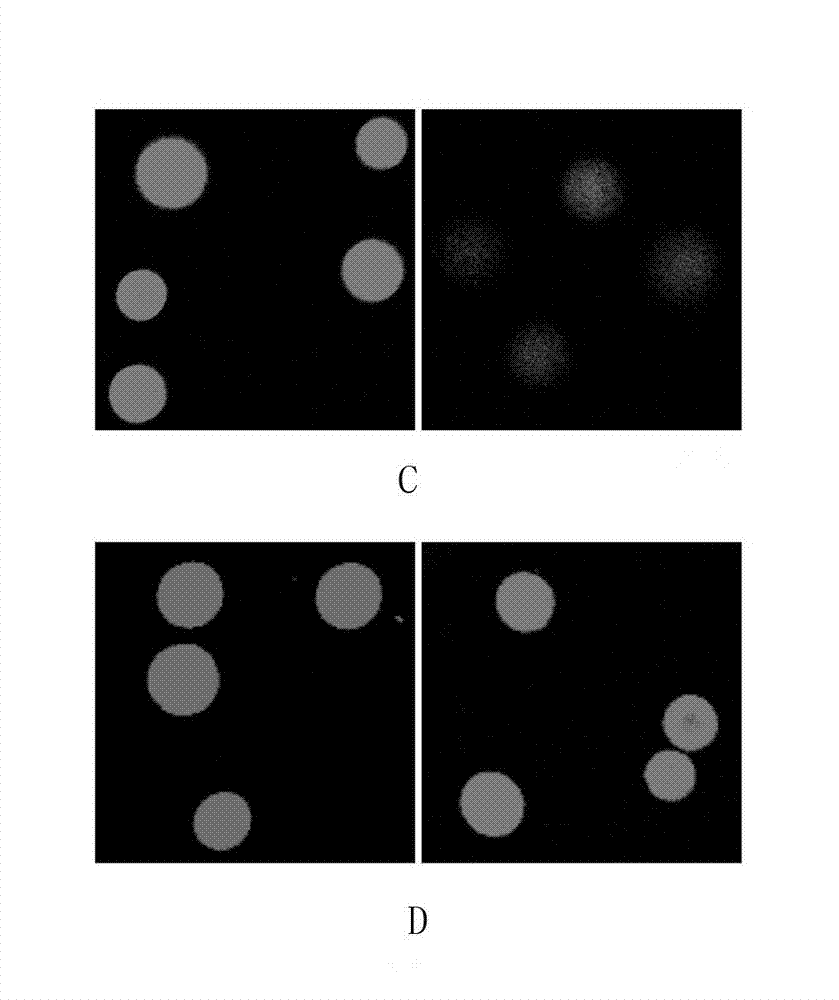

[0039] A group (five types) of quantum dot-agarose composite microspheres of the present invention are all based on honeycomb-shaped agarose gel microspheres (average particle diameter is 35mm), and the pores of the matrix are filled with mercaptoethylamine-modified microspheres. After CdTe quantum dots, each quantum dot is composed of different molar ratios (4:0, 4:0.5, 4:1, 2:1, 0:1, and different molar ratios are combined to express quantum dots of different colors. ) of two kinds of CdTe quantum dots with fluorescence emission wavelengths of 543nm and 602nm are combined, and a layer of polyethyleneimine is attached to the inner wall of each matrix. The amine groups on the CdTe quantum dots are cross-linked into one, and the average number of mercaptoethylamine-CdTe quantum dot particles filled on a single agarose gel microsphere is 1.0×10 8 .

[0040] The method for preparing five kinds of mercaptoethylamine-CdTe quantum dots-agarose composite microspheres of this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com