A method for detecting hydrogen peroxide based on solid-state nanopores

A technology of hydrogen peroxide and nanopores, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as difficult to reflect the kinetic characteristics of enzymes and substrates, and achieve easy design and processing, and easy physical and chemical modification. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

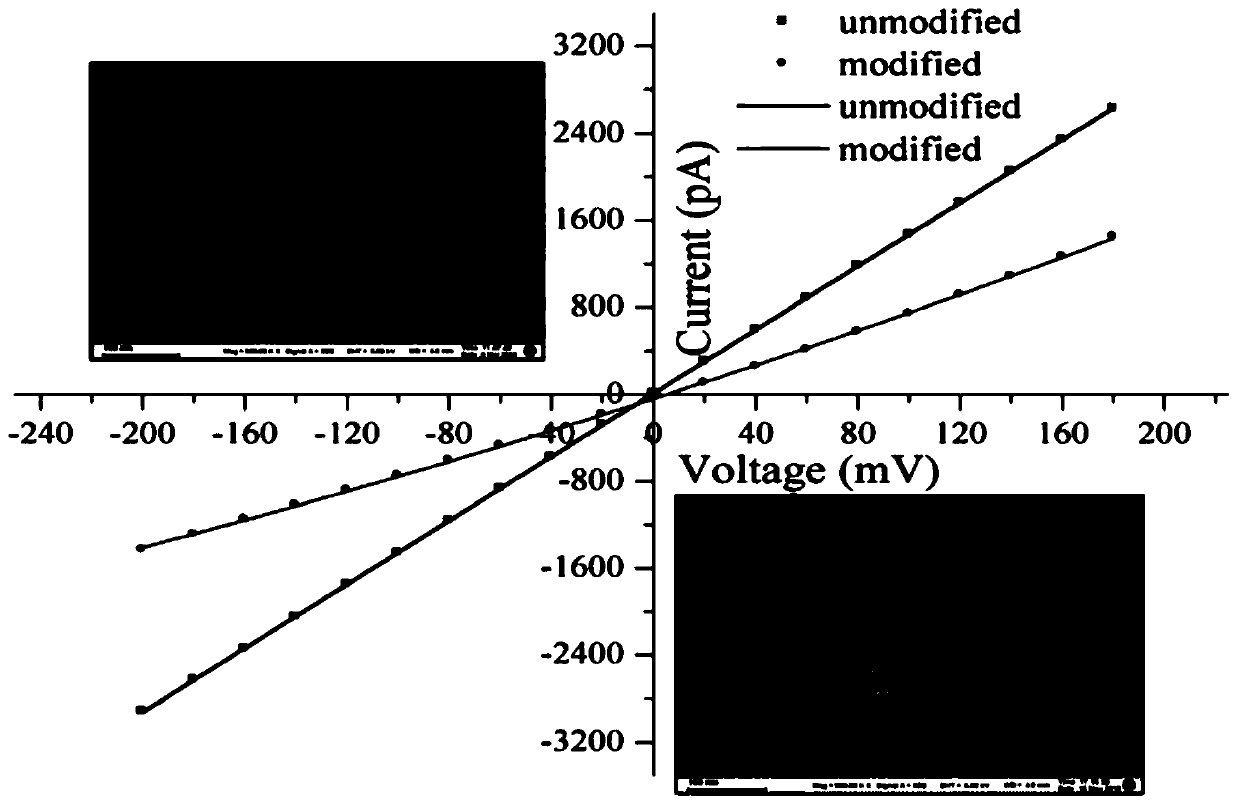

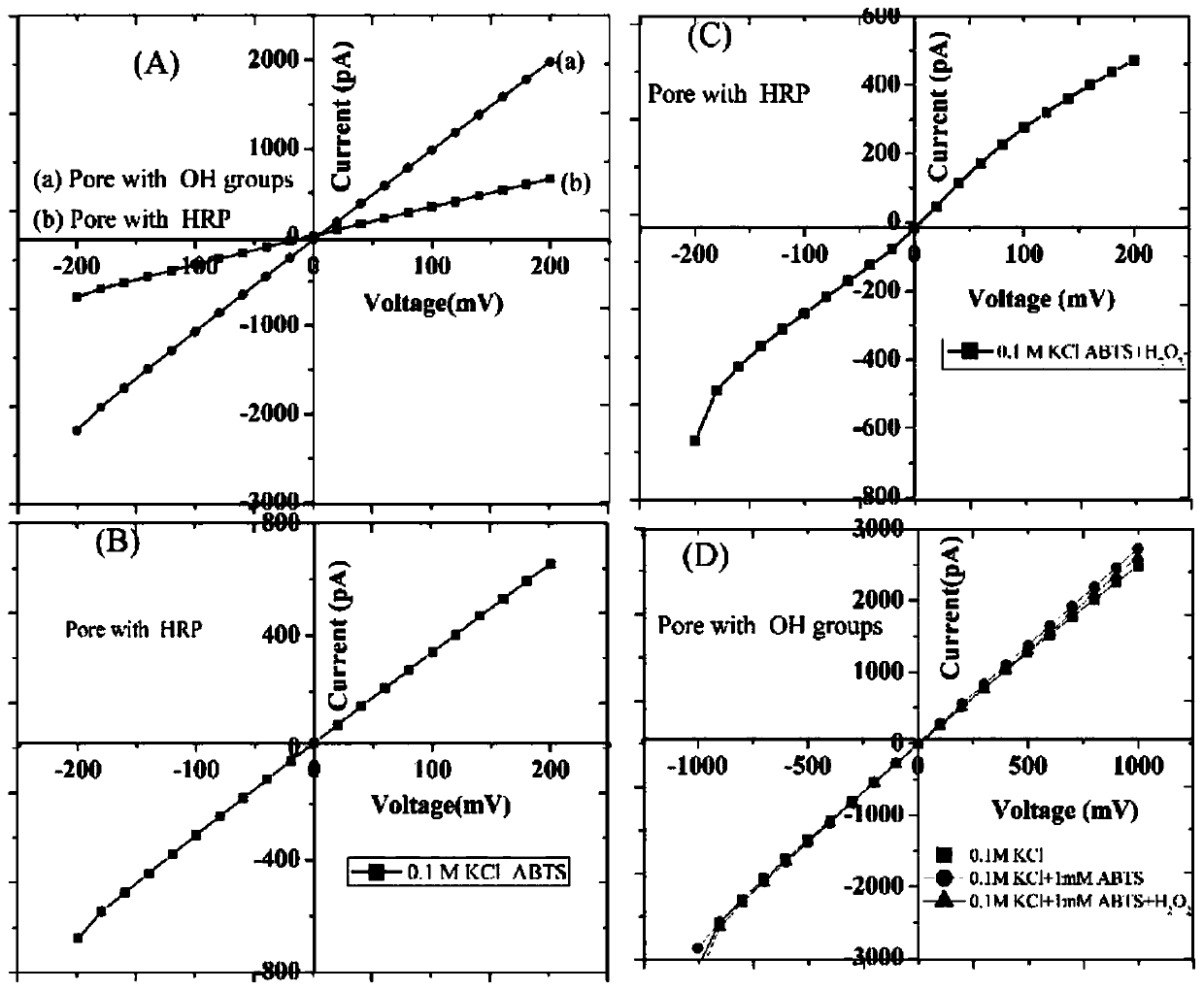

Method used

Image

Examples

preparation example Construction

[0038] 1. Preparation of Nanopores

[0039] The research on the process of preparing high-insulation all-solid-state silicon nitride film has successfully obtained ultra-thin silicon nitride films with various film thicknesses of 30-100nm. Through the optimization of the process, 10-100nm ultra-thin silicon nitride film that meets the drilling requirements will be obtained; through the optimization of the focused electron beam or ion beam processing conditions in the TEM, FIB, and HIM processing system platforms, various thicknesses, The pore size is the aspect ratio, the shape of the nanopore.

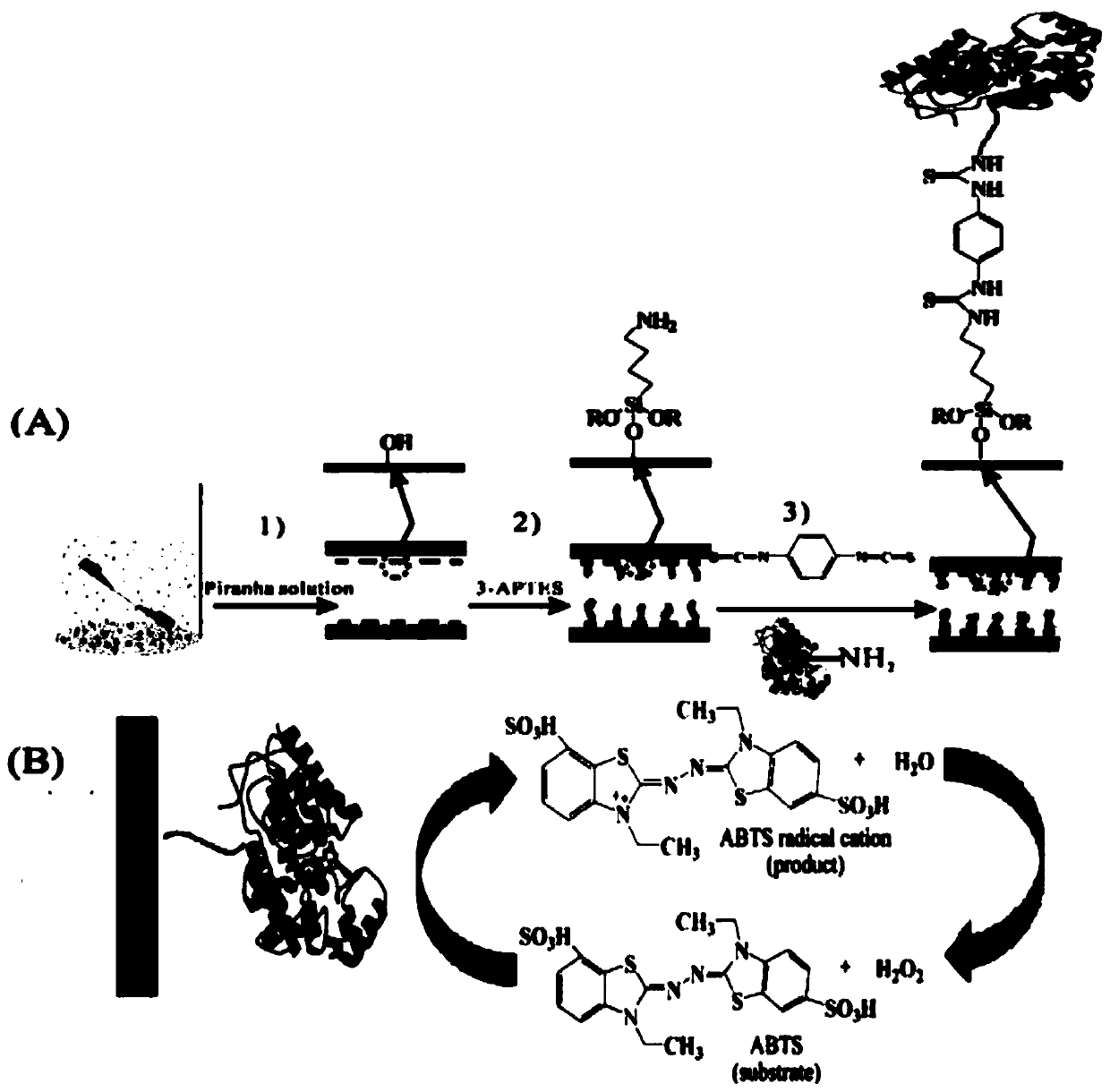

[0040] 2. Modification of nanopores and construction of unimolecular enzyme sensors

[0041] Various silanization treatments (methylsilane, trifluorosilane, carboxysilane, etc.) are used to achieve differential modification of the nanopore surface and inner wall. The peroxidase is coupled to the inner wall of the nanopore through a silane coupling molecule. For example, comb-like g...

Embodiment

[0052] Reagents and materials: APTES, Sigma; potassium chloride (KCl), Sigma; methanol, Sigma; dimethyl sulfoxide, Hefei Xinyuan Biotechnology Co., Ltd.; horseradish peroxidase (HRP), Sigma; ABTS, 98% Sigma; Hydrogen Peroxide (H2O2), 30% SL Labor-Service; Methanol, 98% Sigma; Aminosilane, 98% Sigma;

[0053] Test equipment: field emission scanning electron microscope, Malvern particle size analyzer, analytical balance, vibration isolation table, shielding box, silver wire, pipette gun, ultrapure water, patch clamp,

[0054] Experimental solution preparation

[0055] A. Preparation of 1mol / L KCl solution: Weigh 0.7458g of KCl with an analytical balance, dissolve it, put it in a 10mL volumetric flask, shake well, filter it with an Anotop 0.02μm filter membrane, and then dilute to 0.1mol / L KCl.

[0056] B. Preparation of piranha solution: piranha solution, the ratio is 3:1 (volume ratio) of concentrated sulfuric acid (98%) and hydrogen peroxide solution (30%), prepared in a fum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com