Bionic anticoagulant zwitterionic microgel coating and preparation method thereof

A zwitterion, microgel technology, applied in coating, medical science, surgery, etc., can solve the problems of insufficient stability, low grafting efficiency, complicated preparation process, etc., and achieve excellent anticoagulant performance and simple preparation process. , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

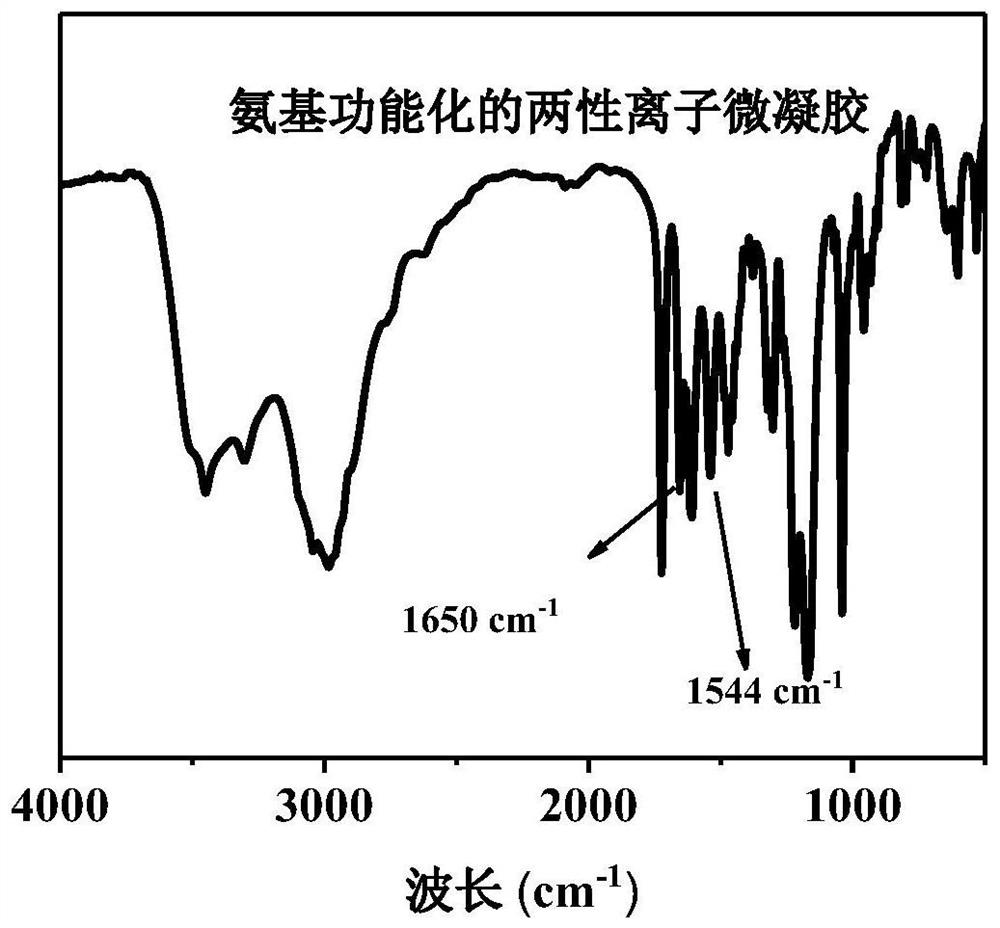

[0050] (1) Weigh 6g of methacryloylethyl sulfobetaine (SBMA), 60mg of potassium persulfate, 1.8g of polyvinylpyrrolidone, 6g of deionized water and 54g of ethanol and added to a 100mL three-necked flask. Stirring was carried out at a speed of 300 rpm under a nitrogen atmosphere, and the reaction temperature was set to 80°C. As the mixture became cloudy, 600 mg of N,N-methylenebisacrylamide and 3 g of 2-aminoethylmethacrylate were slowly added dropwise to the mixed solution. After the dropwise addition, the reaction was continued for 2 hours to obtain a milky white microgel suspension. The resulting microgel suspension was centrifuged at 2000 rpm, washed three times with ethanol, and dried in vacuo to obtain a purified amino-functionalized zwitterionic microgel. like figure 1 shown, the infrared spectra of the prepared amino-functionalized zwitterionic microgels. From the infrared spectrum, it can be seen that the amino-functionalized zwitterionic microgel is at 1640 cm -1 ...

Embodiment 2

[0056] (1) Weigh 4.5 g of methacryloylethyl sulfobetaine (SBMA), 20 mg of ammonium persulfate, 0.9 g of polyvinylpyrrolidone, 15 g of deionized water and 45 g of ethanol into a 100 mL three-necked flask. Stirring was carried out at 300 rpm under nitrogen atmosphere, and the reaction temperature was set at 40°C. As the mixture became cloudy, 100 mg of N,N-methylenebisacrylamide and 2.2 g of 2-aminoethyl methacrylate were slowly added dropwise to the mixed solution. After the dropwise addition, the reaction was continued for 24 hours to obtain a milky white microgel suspension. The resulting microgel suspension was centrifuged at 1000 rpm, washed three times with ethanol, and dried in vacuo to obtain a purified amino-functionalized zwitterionic microgel.

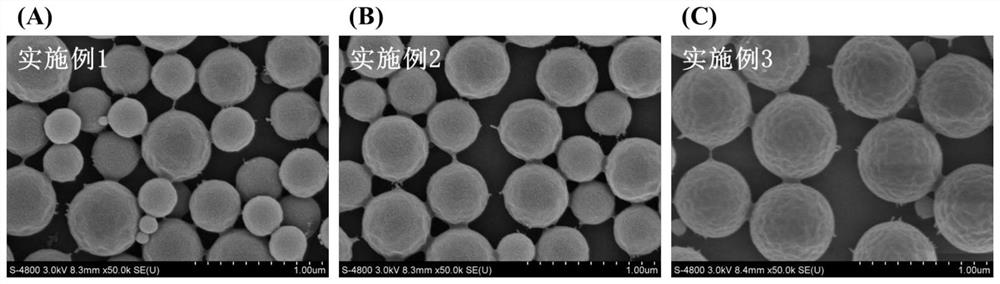

[0057] figure 2 (B) is an SEM of the amino functionalized zwitterionic microgel prepared in Example 2. The SEM images showed that the amino-functionalized zwitterionic microgels were uniform in size and monodispersed spher...

Embodiment 3

[0061] (1) Weigh 6g of methacryloylethylsulfobetaine (SBMA), 20mg of ammonium persulfate, 0.3g of polyvinylpyrrolidone, 6g of deionized water and 54g of ethanol into a 100mL three-necked flask. Stirring was carried out at 300 rpm under nitrogen atmosphere, and the reaction temperature was set at 40°C. As the mixture became cloudy, 300 mg of N,N-methylenebisacrylamide and 0.8 g of N-(3-aminopropyl)methacrylamide were slowly added dropwise to the mixed solution. After the dropwise addition, the reaction was continued for 20 hours to obtain a milky white microgel suspension. The resulting microgel suspension was centrifuged at 7000 rpm, washed three times with ethanol, and vacuum dried to obtain a purified amino-functionalized zwitterionic microgel.

[0062] figure 2 (C) is an SEM of the amino functionalized zwitterionic microgel prepared in Example 3. The SEM images showed that the amino-functionalized zwitterionic microgels were uniform in size and monodispersed spherical p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com