Building member combining keel frame assembly and heat insulation plate

A technology of building components and thermal insulation boards, which is applied in the direction of building components, building structures, thermal insulation, etc., can solve problems such as falling off and unsatisfactory holding effect, and achieve the effects of convenient installation and construction, good slurry grasping effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

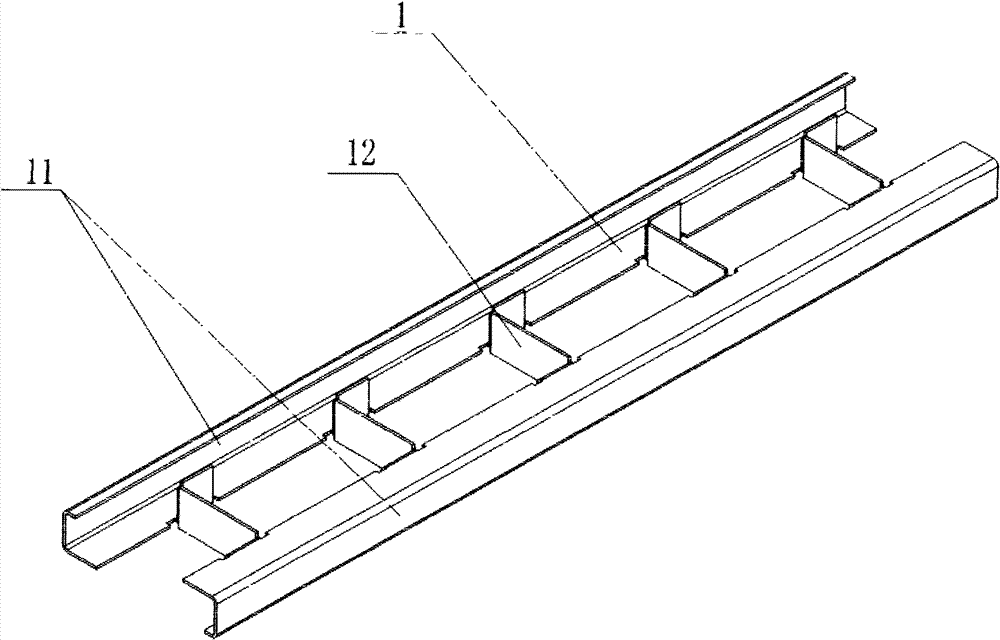

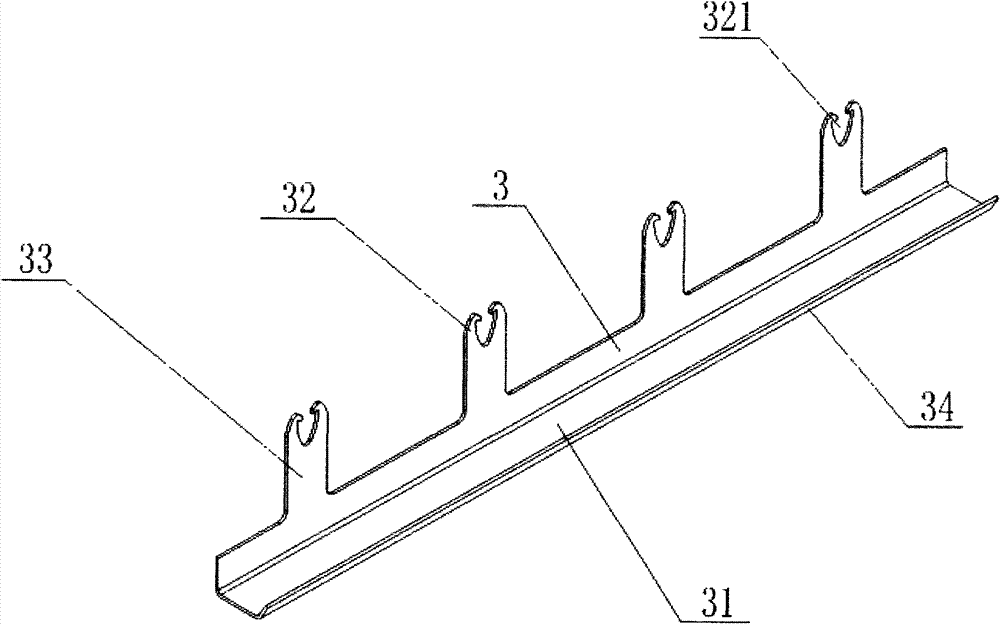

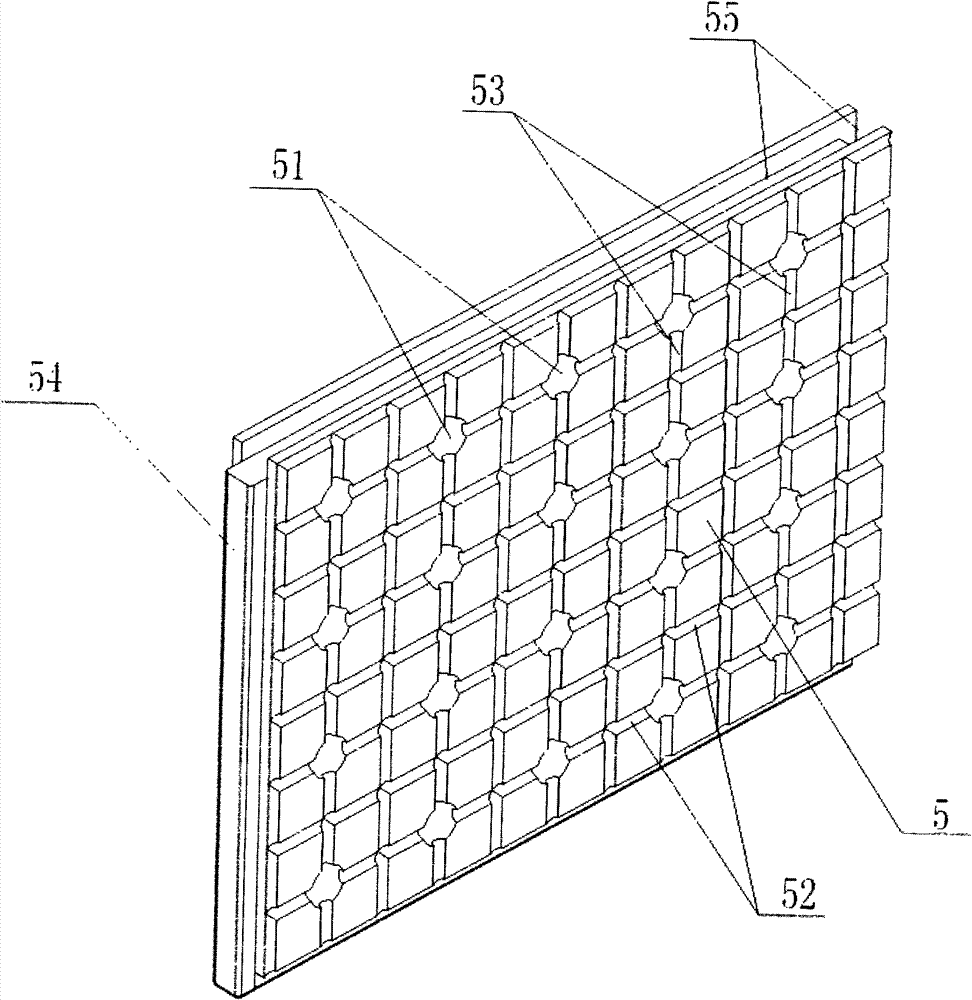

[0029] Please refer to the attached Figure 1 to Figure 7 As shown, the present invention is a building component combined with a keel frame assembly and a thermal insulation board, which is used for pouring concrete walls, and is mainly composed of keels, clips 3, thermal insulation boards 5 and reinforced steel mesh 7 and other components. The above keel is specifically expansion keel 1 (such as figure 1 , 5 and 7) or C-shaped opening keel 1' (such as Figure 6 shown) or a C-shaped keel without holes, the following only describes the specific implementation of the expansion keel 1, and in actual use, it is only necessary to replace the expansion keel 1 with other forms of keel.

[0030] Wherein, the expansion keels 1 are arranged at equal intervals, and the number thereof varies according to the size and strength of the wall. The expanded keel 1 includes a pair of oppositely arranged main ribs 11 and ribs 12 disposed between the two main ribs 11 and arranged at equal inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com