Device and method for avoiding stall caused by strong wind in vertical axis wind turbine

A wind turbine, vertical axis technology, applied in wind turbine components, control of wind turbines, wind turbines at right angles to the wind direction, etc., can solve problems such as generator stalls, broken blades, etc. Simple, secure results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

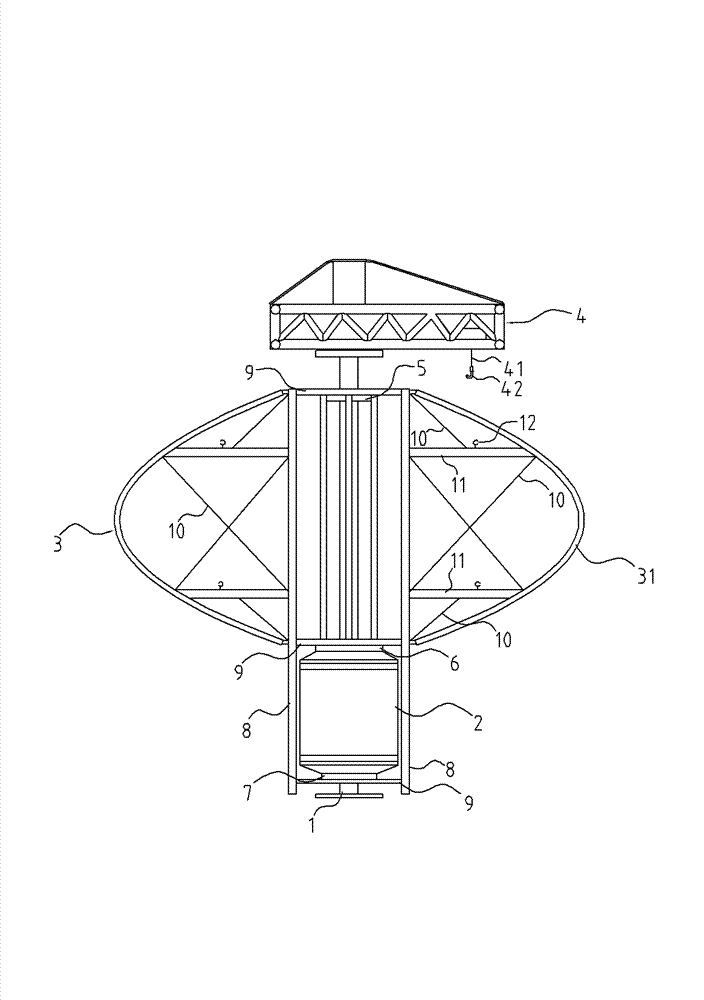

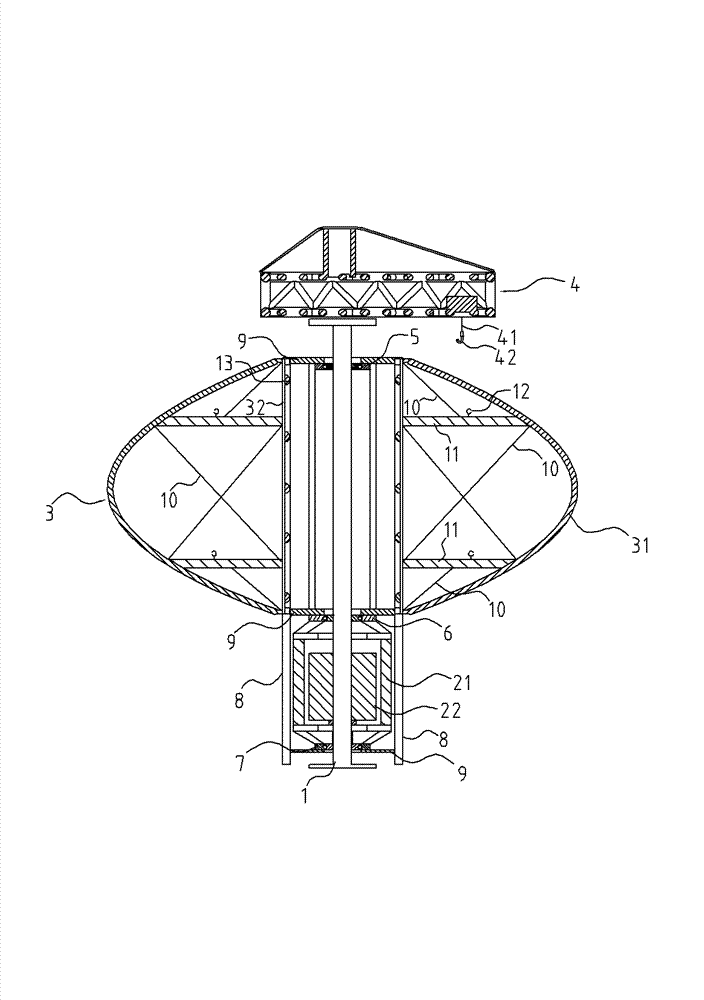

[0038] like figure 1As shown, a device for avoiding a stall caused by strong wind of a vertical axis wind power generator includes a tower column 1 and more than one power generation unit arranged on the tower column 1. In this embodiment, only one A power generation unit, the power generation unit includes a Φ-shaped blade group, an outer rotor generator 2 and a crane 4 .

[0039] like figure 2 As shown, the upper end of the Φ-shaped blade group is provided with a first bearing 5, the inner ring of the first bearing 5 is fixedly sleeved on the tower column 1, and the upper end of the Φ-shaped blade group is connected with the outer ring of the first bearing 5; The lower end of the group is provided with a second bearing 6, the inner ring of the second bearing 6 is fixedly sleeved on the tower column 1, the lower end of the blade group is connected with the outer ring of the second bearing 6, and the blade group is connected to the second bearing 6 through the first bearing ...

Embodiment 2

[0046] like Figure 4 As shown, a device for avoiding a stall caused by strong wind of a vertical axis wind power generator includes a tower column 1 and more than one power generation unit arranged on the tower column 1. In this embodiment, the tower column 1 is only provided with two A power generation unit arranged up and down, the power generation unit includes a Φ-shaped blade group, an outer rotor generator 2, and a crane 4.

[0047] like Figure 5 As shown, the upper end of the blade group is provided with a first bearing 5, the inner ring of the first bearing 5 is fixedly sleeved on the tower column 1, and the upper end of the blade group is connected with the outer ring of the first bearing 5; the lower end of the blade group is provided with a second Bearing 6, the inner ring of the second bearing 6 is fixedly sleeved on the tower column 1, the lower end of the blade group is connected to the outer ring of the second bearing 6, and the blade group is pivotally conne...

Embodiment 3

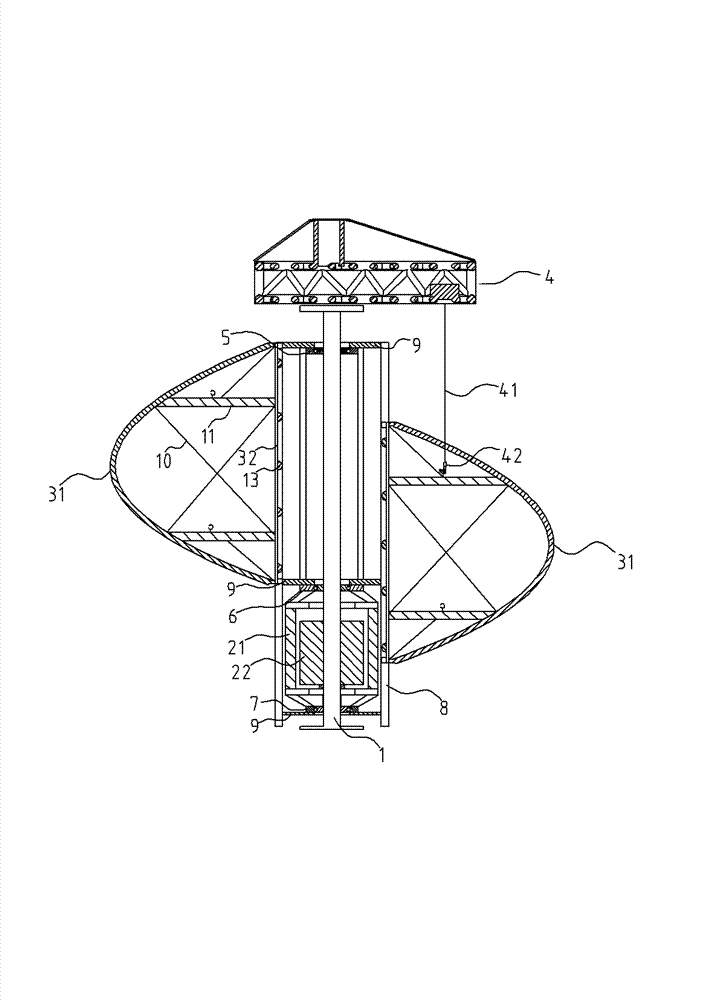

[0054] like Figure 7 As shown, a device for avoiding a stall caused by strong wind of a vertical axis wind power generator includes a tower column 1 and more than one power generation unit arranged on the tower column 1. In this embodiment, the tower column 1 is only provided with two A power generation unit arranged up and down, the power generation unit includes a Φ-shaped blade group, an outer rotor generator 2, and a crane 4.

[0055] like Figure 8 As shown, the upper end of the blade group is provided with a first bearing 5, the inner ring of the first bearing 5 is fixedly sleeved on the tower column 1, and the upper end of the blade group is connected with the outer ring of the first bearing 5; the lower end of the blade group is provided with a second Bearing 6, the inner ring of the second bearing 6 is fixedly sleeved on the tower column 1, the lower end of the blade group is connected to the outer ring of the second bearing 6, and the blade group is pivotally conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com