Method for measuring track direction and horizontal irregularity based on plot points

A measurement method and track technology, which is applied in the field of railway maintenance and rail transit, and can solve problems such as inability to directly measure the direction and level of the track, affecting the accuracy of the measurement method, and large cumulative errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be further described now in conjunction with accompanying drawing:

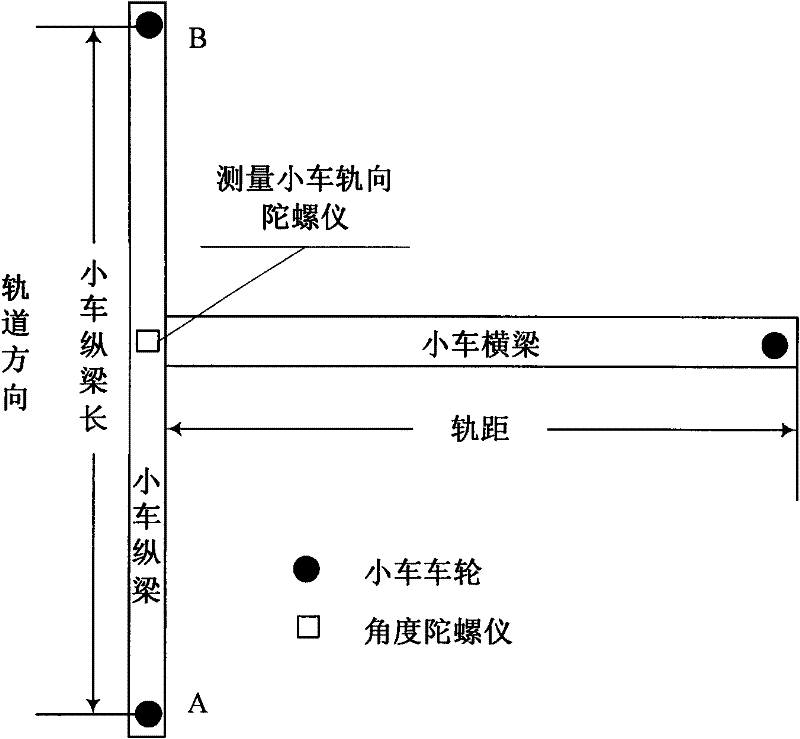

[0100] The present invention adopts a section of track with a length of 500 meters as the test track, i.e. dis=500000 mm, the right track in the forward direction is the reference track, the left track is the measurement track, and the XK120 type single-axis open-loop fiber optic gyroscope is used as the swing angle sensitive test track. Components; the hardware environment used to implement the calculation of the present invention is: P43.0Ghz dual-core CPU, internal memory 2.0G, hard disk 80G; Windows XP Professional operating system, NTFS file system; data processing program adopts VC++6.0 to realize.

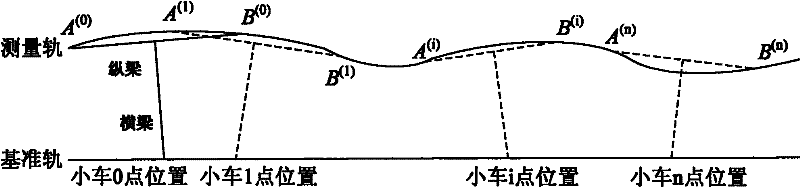

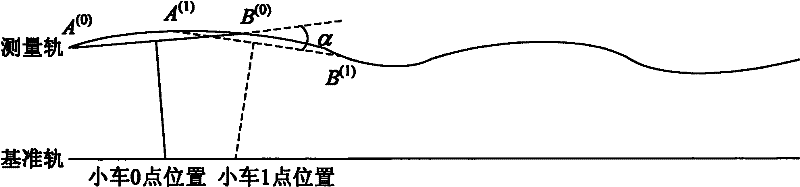

[0101] Step 1. Install the trolley on the measuring rail: correctly install the rail inspection trolley on the track to be tested, power on and work, record the contact point between the A wheel and B wheel on the rigid longitudinal beam of the trolley and the track as A (0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com