Piezoelectric detection device based on LSAW (laser surface acoustic wave) locating of PVDF (Polyvinylidene Fluoride) piezoelectric thin film

A piezoelectric thin film and detection device technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of inability to accurately locate and measure the direction of ultrasonic propagation, and achieve the effect of real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

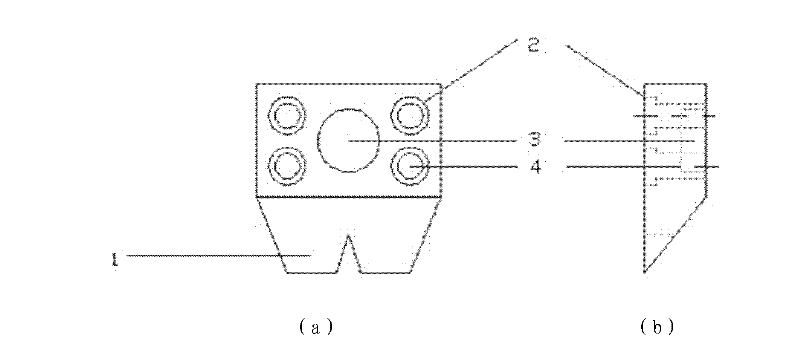

[0018] The technical problem to be solved by the present invention is to provide a method capable of orienting ultrasound and simultaneously detecting surface acoustic wave signals at different positions, which can effectively locate the propagation direction of ultrasound with a simple structure, and the key part of the invention It can be made of cheap and easy-to-process materials.

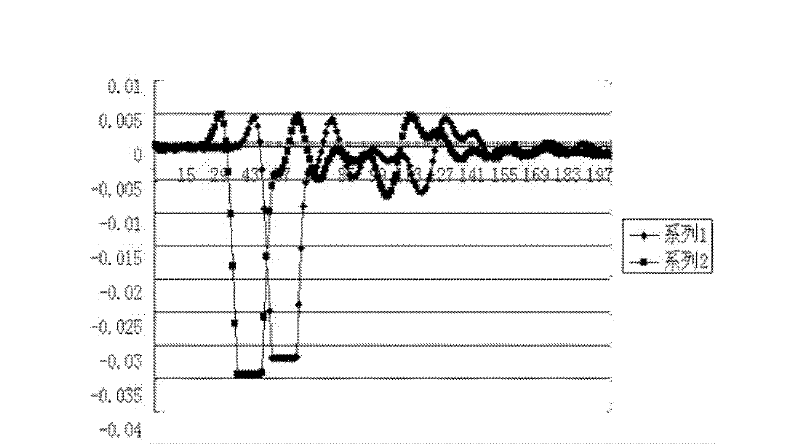

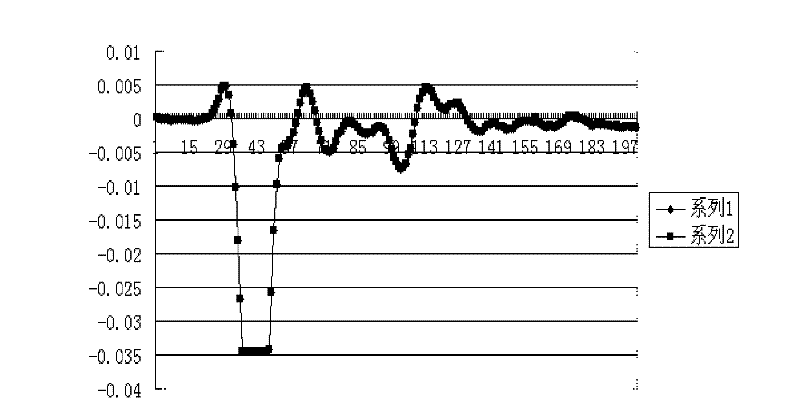

[0019] In order to solve the above-mentioned technical problems, the present invention consists of two parts, a PVDF piezoelectric sensor and a piezoelectric probe, which are independent of each other. The PVDF piezoelectric sensor and the piezoelectric probe are connected flexibly, so the contact position between the probe and the piezoelectric sensor can be adjusted more conveniently. . Among them, the PVDF piezoelectric sensor is divided into four quadrants, each quadrant is separated from each other, and each quadrant leads to two electrodes, and finally the four piezoelectric signals are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com