Method for accurately detecting surface quality on line in production process of band steel

A production process, surface quality technology, applied in the direction of optical testing flaws/defects, etc., can solve the problem of not being able to realize online detection and classification of multiple defects at the same time, real-time, comprehensive and accurate detection and classification of strip surface defects, and no proposed detection and classification methods to achieve the effect of improving the defect recognition rate, solving the low detection accuracy rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

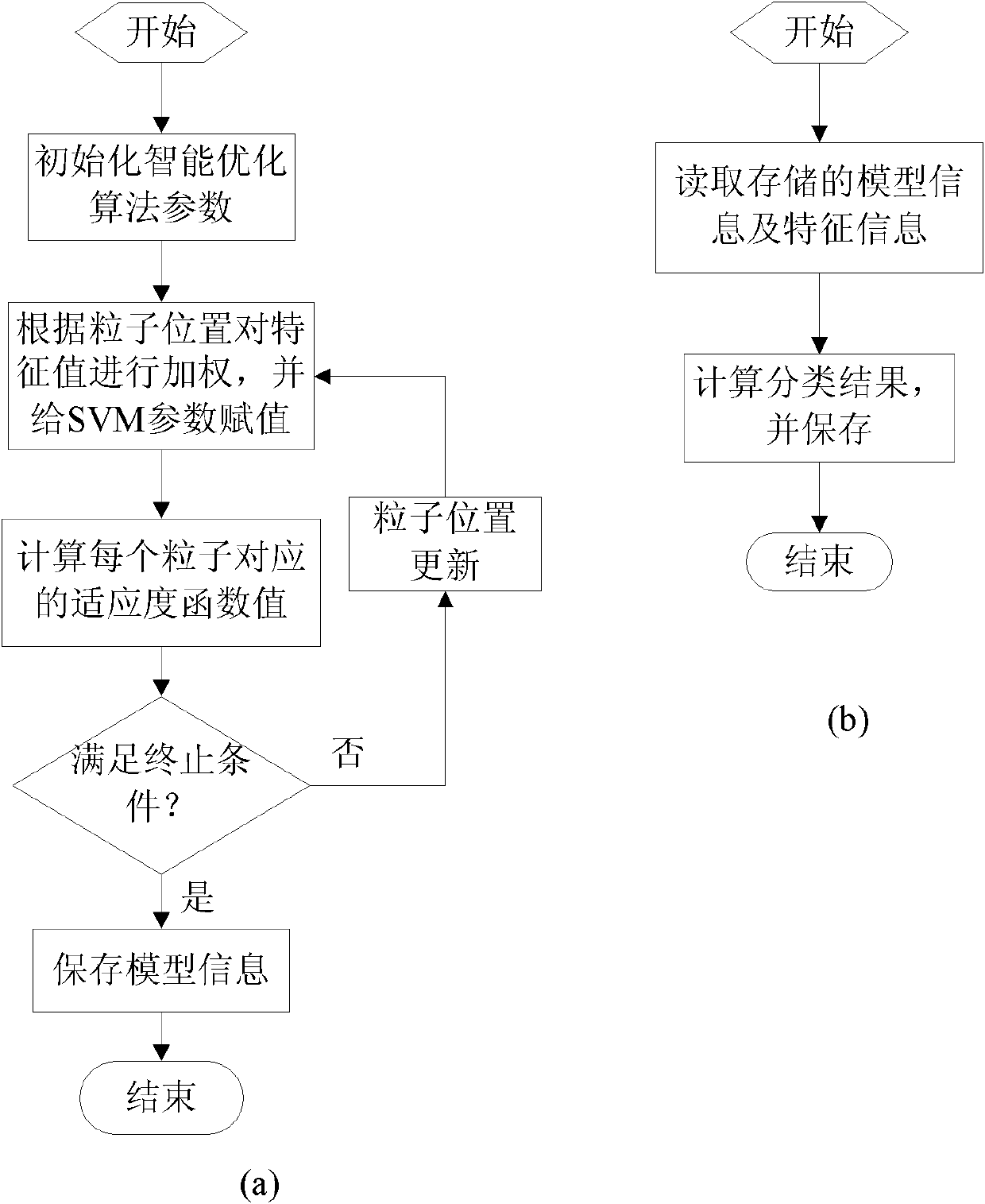

[0078] The intelligent optimization algorithm in this embodiment adopts the particle swarm optimization algorithm PSO, and the defect classification adopts a method combining the support vector machine SVM and the particle swarm optimization algorithm PSO.

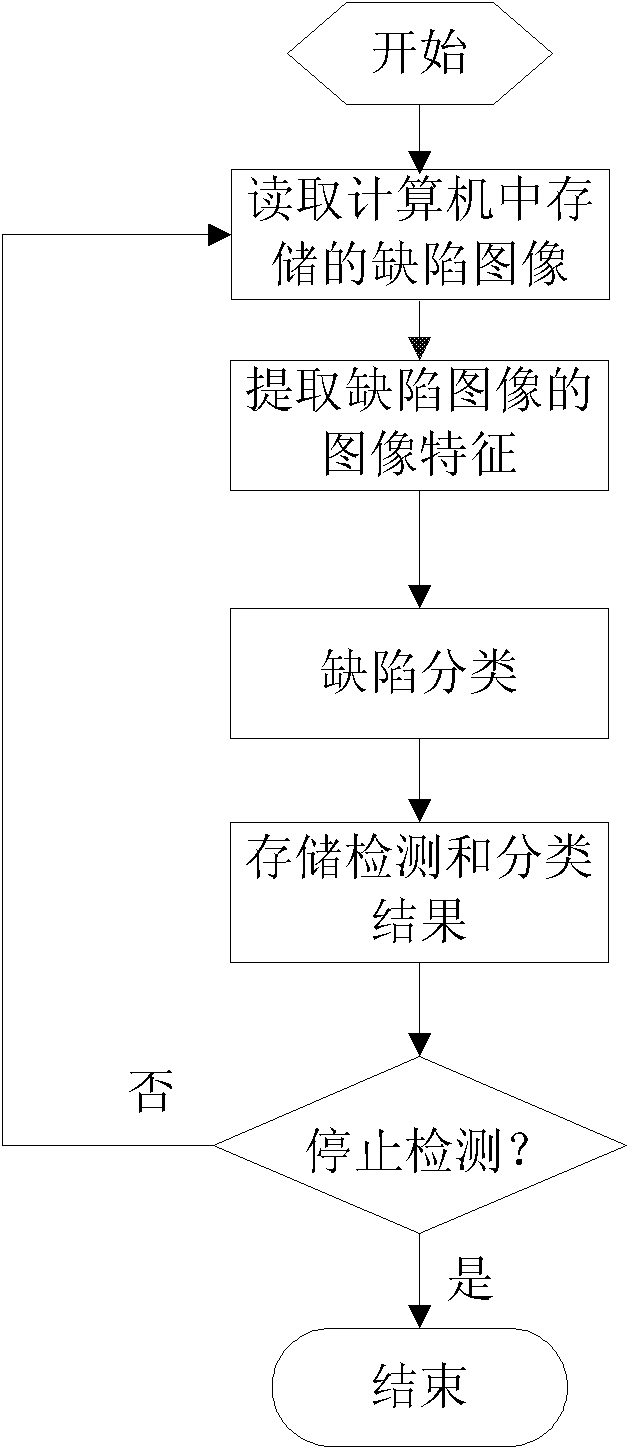

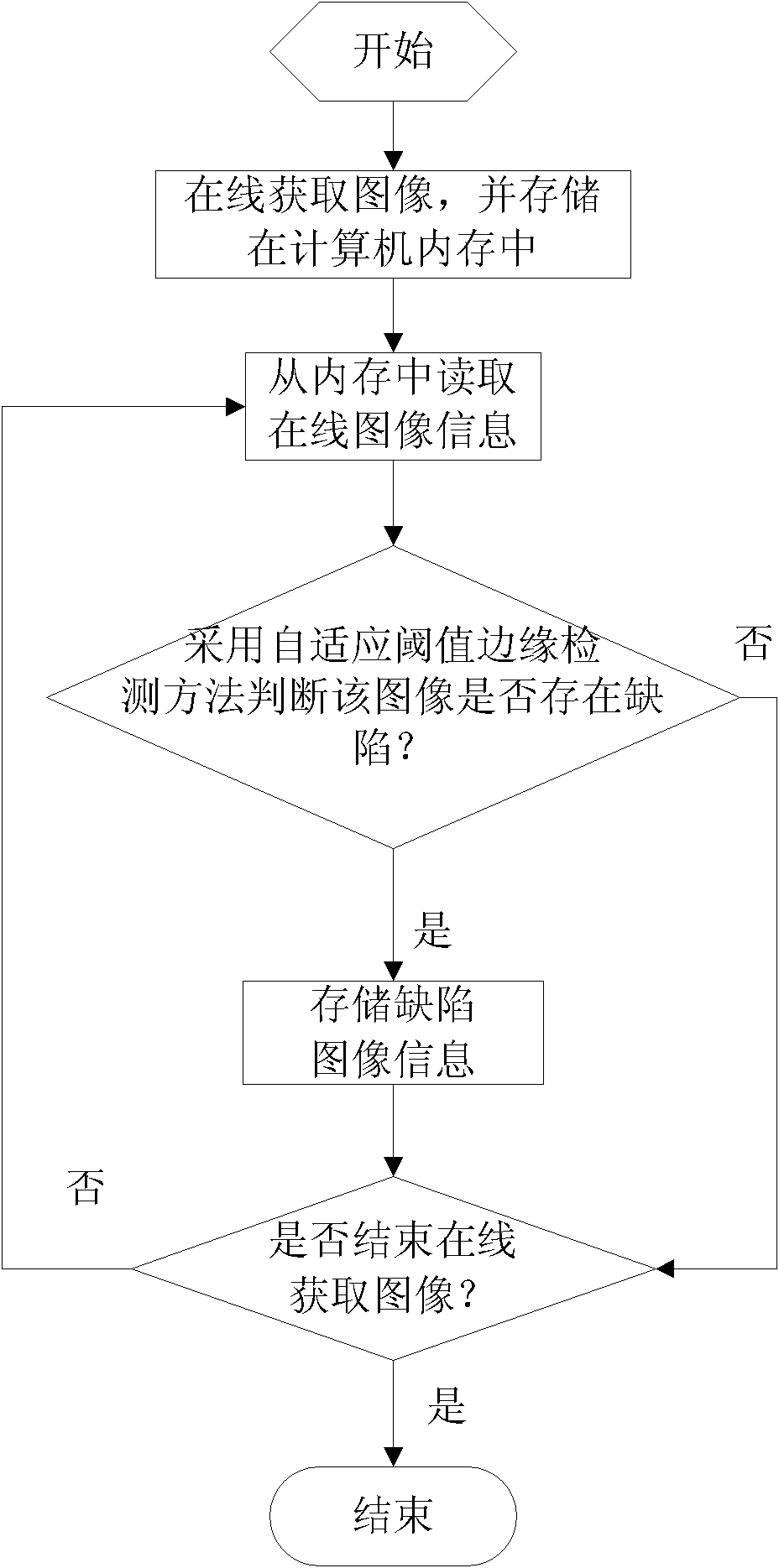

[0079] Step 1: online acquisition of defect images, the specific steps are as follows:

[0080] Step a: After the photosensitive element on the camera of the camera senses the target, the photosensitive element converts the light intensity signal into an electrical signal and transmits it through the transmission device. Each time a row of images is transmitted, the computer combines a certain number of rows of images into one The images are then stored in the memory of the computer;

[0081] Step b: read an image from the memory of the computer;

[0082] Step c: Use an adaptive threshold edge detection method to judge whether the image has defects. The defect of the image mentioned in the present invention refers to whet...

Embodiment 2

[0122] The intelligent optimization algorithm in this embodiment adopts the differential evolution algorithm DE, and the defect classification adopts a method combining the support vector machine SVM and the differential evolution algorithm DE.

[0123] Step 1: online acquisition of defect images, the specific steps are as follows:

[0124] Step a: After the photosensitive element on the camera of the camera senses the target, the photosensitive element converts the light intensity signal into an electrical signal and transmits it through the transmission device. Each time a row of images is transmitted, the computer combines a certain number of rows of images into one The images are then stored in the memory of the computer;

[0125] Step b: read an image from the memory of the computer;

[0126] Step c: Use an adaptive threshold edge detection method to judge whether the image has defects. The defect of the image mentioned in the present invention refers to whether there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com