Integrated standard device for field calibration of extra/ultra high voltage capacitor voltage transformer (CVT)

An on-site calibration and standard device technology, applied in the direction of measuring devices, instruments, measuring electronics, etc., can solve the difficulty in meeting the needs of measurement accuracy and work efficiency, the additional error of the measurement system is not fixed, and the uncertainty of the distribution parameters is increased and other problems, to reduce the difficulty of insulation design, reduce measurement uncertainty, and reduce the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

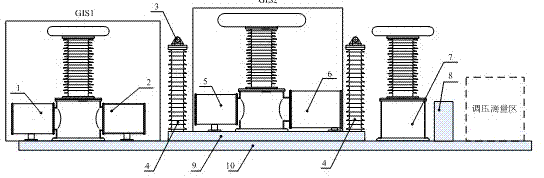

[0021] figure 1 Instructions for marks in: 1-lower standard voltage transformer, 2-high voltage isolation transformer, 3-transmission mechanism, 4-insulation support, 5-superior standard voltage transformer, 6-superior test transformer, 7-lower test transformer , 8-secondary compensation reactor, 9-base, 10-vehicle platform.

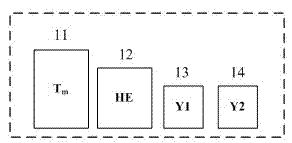

[0022] figure 2 Explanation of the marks in: 11 - Regulator T m , 12-transformer calibrator HE, 13-load box Y1, 14-load box Y2.

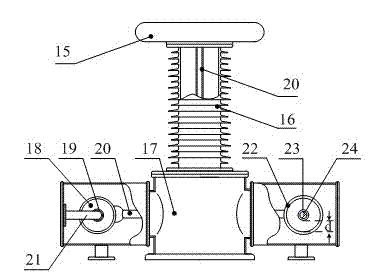

[0023] image 3 Description of the marks in: 15-voltage equalizing ring, 16-high voltage bushing, 17-tee connection body, 18-standard transformer high-voltage winding, 19-standard transformer low-voltage winding, 20-high voltage conductor, 21-transformer iron Core, 22-HVIT high-voltage winding, 23-HVIT low-voltage winding, 24-HVIT iron core, d-insulation distance between coaxial electrodes.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com