Automatic upright metallurgical microscope

A metallographic microscope, upright technology, applied in the field of microscopes, can solve the problems of inability to realize free conversion and automatic focusing of objective lenses, expensive electric control equipment, expensive equipment, etc., to achieve automatic focusing, convenient focusing operation, Cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

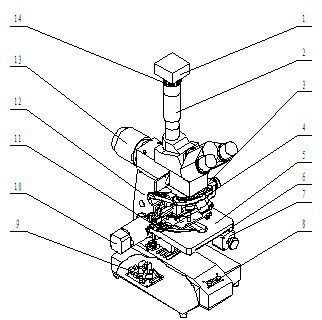

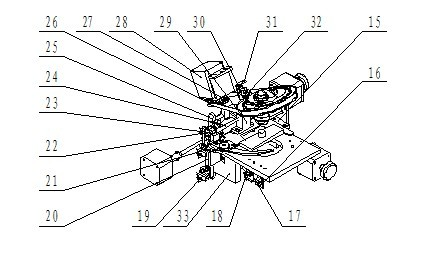

[0020] See figure 1 combine figure 2 .

[0021] A CCD1 is set on the top of the lens barrel 2, under the CCD1 is a CCD interface 14, and the workbench is an X-direction platen 11 and a Y-direction platen respectively controlled by an X-direction stepping motor 3, a Y-direction stepping motor 7, and a Z-direction stepping motor 10. 5. The three-axis linkage workbench composed of the Z-direction platen 6, the objective lens is installed on the objective lens converter 4 controlled by the W-axis stepping motor 28, and the single-chip microcomputer 9 that can receive PC instructions and process and digitally adjust the light source is set on in the circuit board inside the microscope.

[0022] The main function of the electric adjustment mechanism in the X, Y, and Z directions of the workbench is to automatically adjust the focus. The control mechanism includes a three-axis linkage workbench, an X-direction stepping motor 3, a Y-direction stepping motor 7, a Z-direction steppi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com