Method for optimizing coherent factor of photoetching machine lighting system

A technology of coherence factor and lighting system, applied in the field of coherence factor optimization of lithography machine lighting system, can solve the problems of large amount of calculation, low precision, difficulty in finding the optimal coherence factor, etc., and achieve the effect of small amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

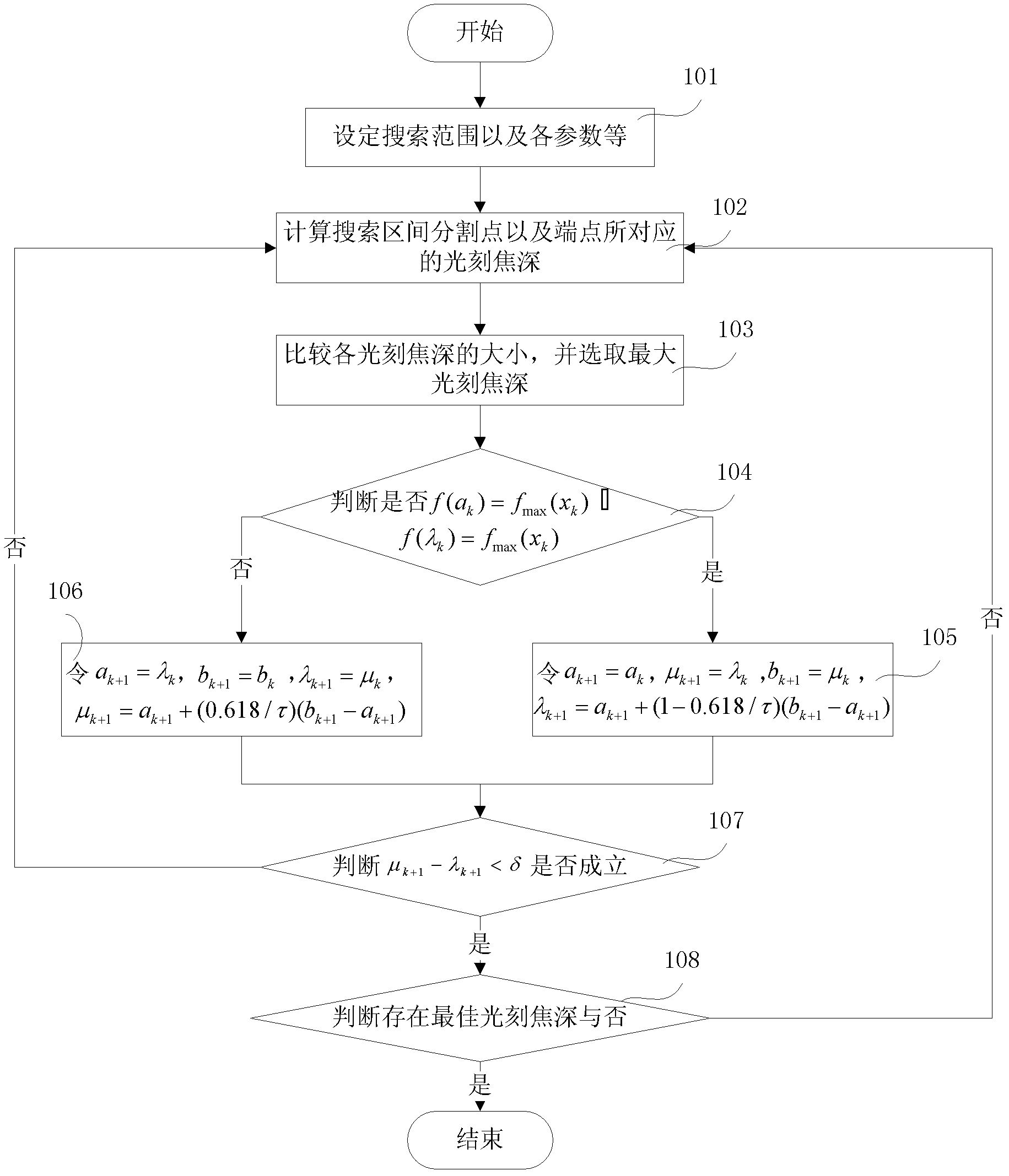

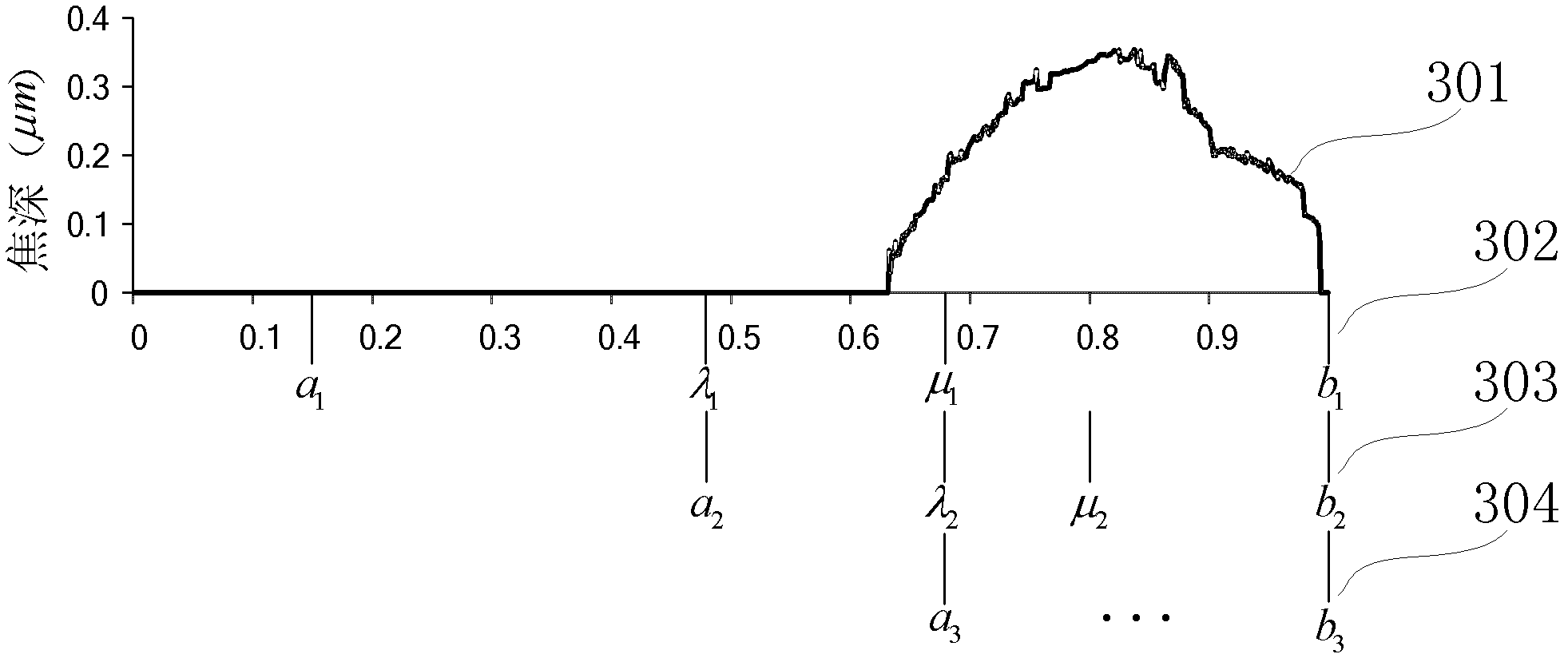

[0035] For example, the value range of the coherence factor is [0.3, 1], and the precision of the coherence factor is 0.001. If the existing ergodic calculation method is used, it is necessary to let the coherence factor take a value every 0.001 from 0.3 to 1 for simulation one by one, so that a total of 701 values need to be taken, that is, 701 calculations are required to obtain the best coherence factor value. If the optimization method of the present invention is sampled, the accuracy of the coherence factor required by us can be achieved and the optimum value of the coherence factor can be obtained only by calculating more than 20 times. Therefore, compared with the prior art, the present invention has a fast calculation speed and can meet the requirement of high-precision calculation.

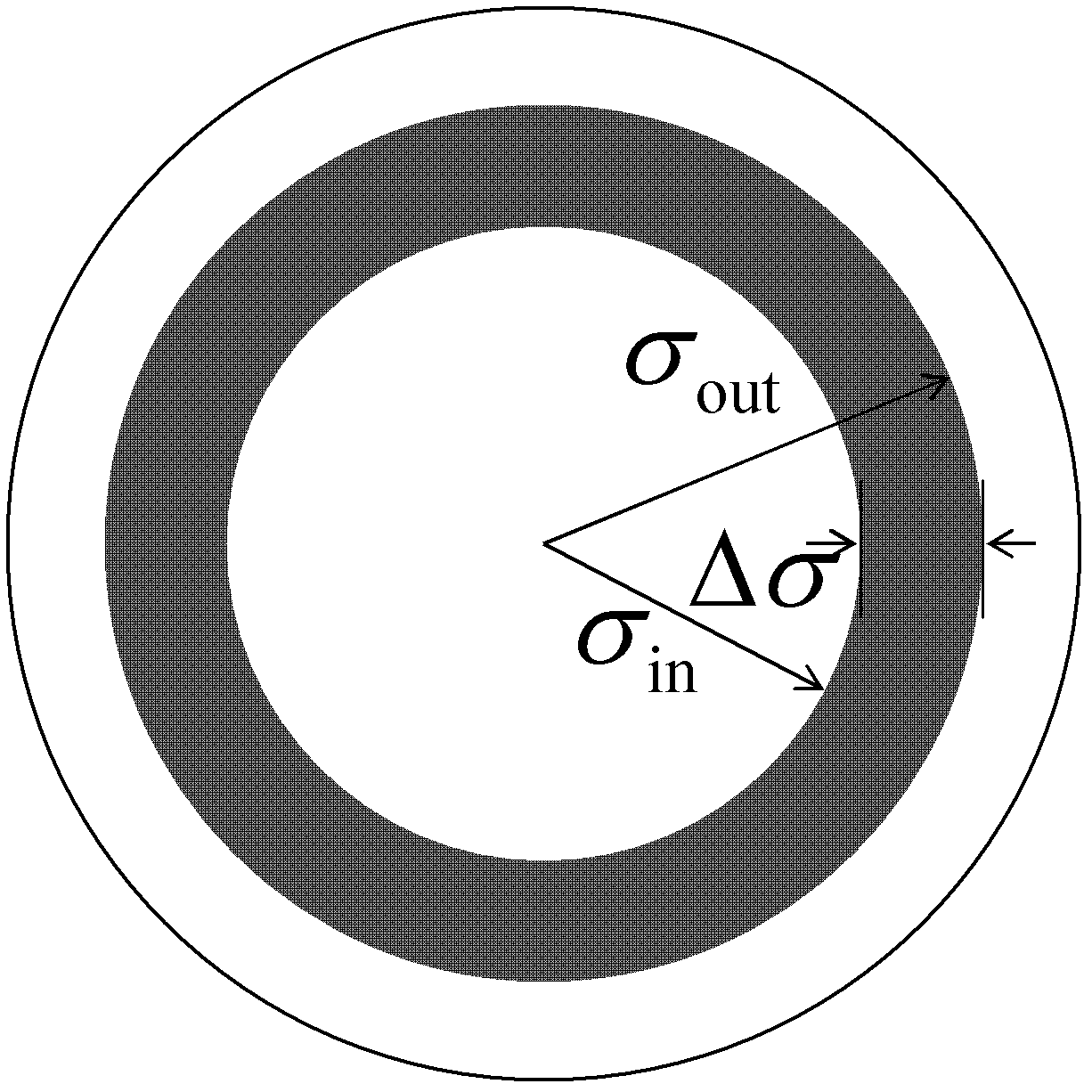

[0036] The optimization process of the present invention will be described below by taking the optimization of the external coherence factor as an example for a lithography machine ill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com