PN junction isolating structure and forming method thereof

A technology of isolation structure and PN junction, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as occupancy and large chip area, achieve simple process, reduce the possibility of self-doping, and better control the epitaxial growth process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

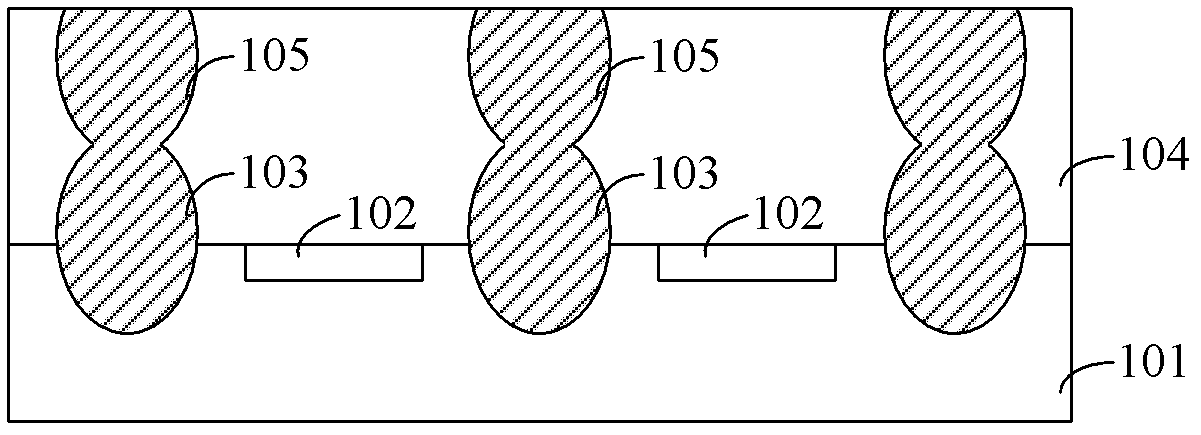

[0034] In the formation process of the PN junction isolation structure in the prior art, the lower isolation region and the upper isolation region are often formed first, and then the two are connected up and down through annealing advancement, but long-term annealing advancement will cause severe lateral diffusion, making The PN junction isolation structure occupies a larger chip area.

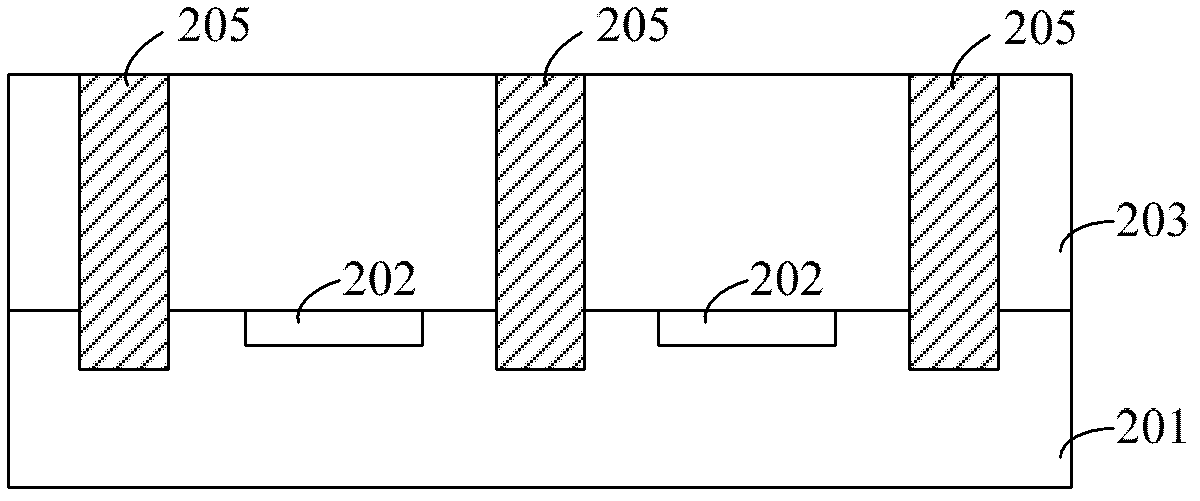

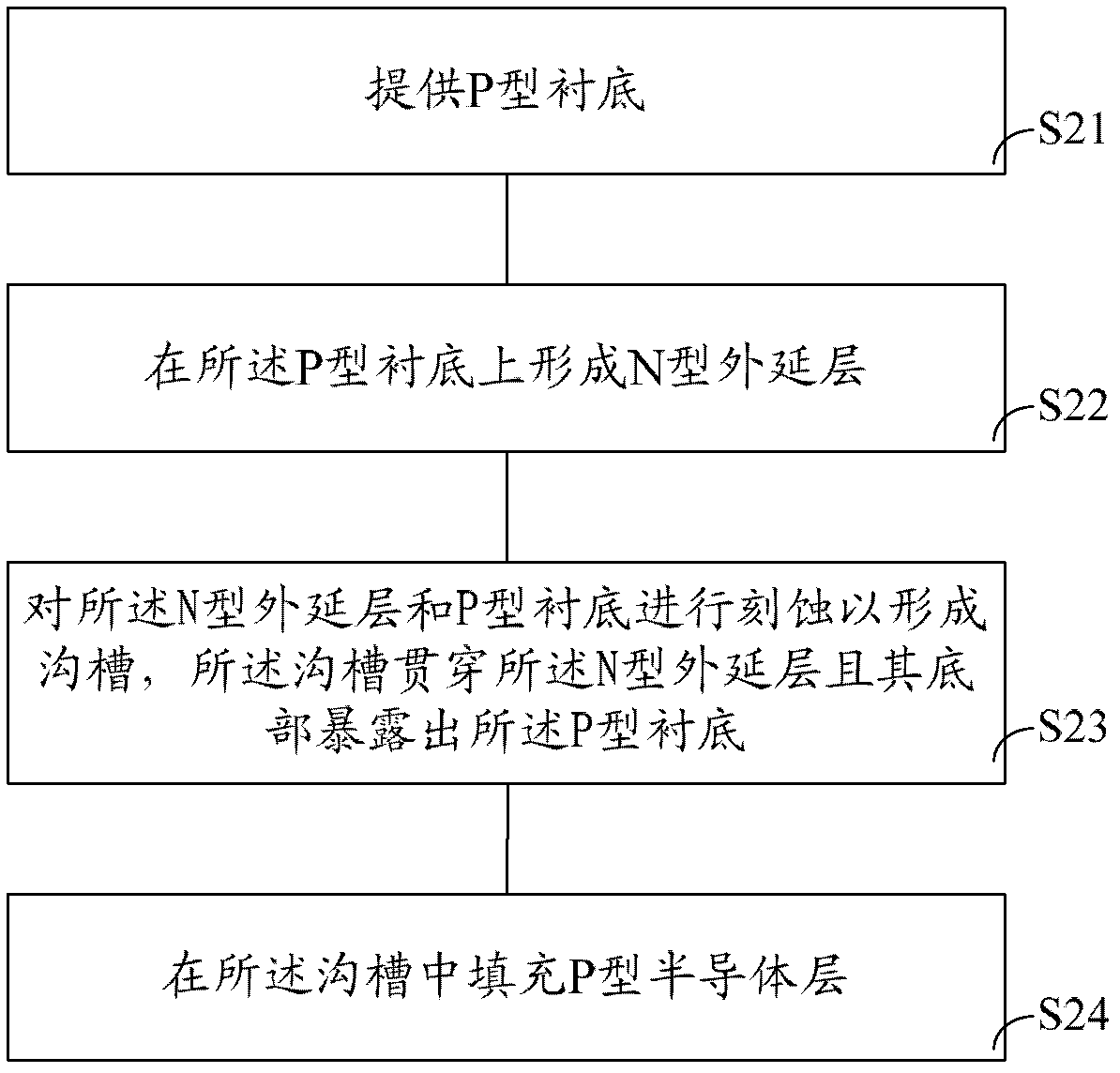

[0035] In the PN junction isolation structure and its forming method of the embodiment of the present invention, a trench is first formed on the N-type epitaxial layer, and then a P-type semiconductor layer is filled in the trench, which avoids the heat generated during the formation of the traditional PN junction isolation structure. The problem is that the process is long, the lateral diffusion is serious, and the isolation structure occupies a large chip area, and the doping concentration of the P-type semiconductor layer in the PN junction isolation structure of this embodiment is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com