Brake system of a rail vehicle with compensation of fluctuations of the friction conditions

A technology for braking equipment and rail vehicles, which can be used in vehicle components, brakes, brake components, etc., and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

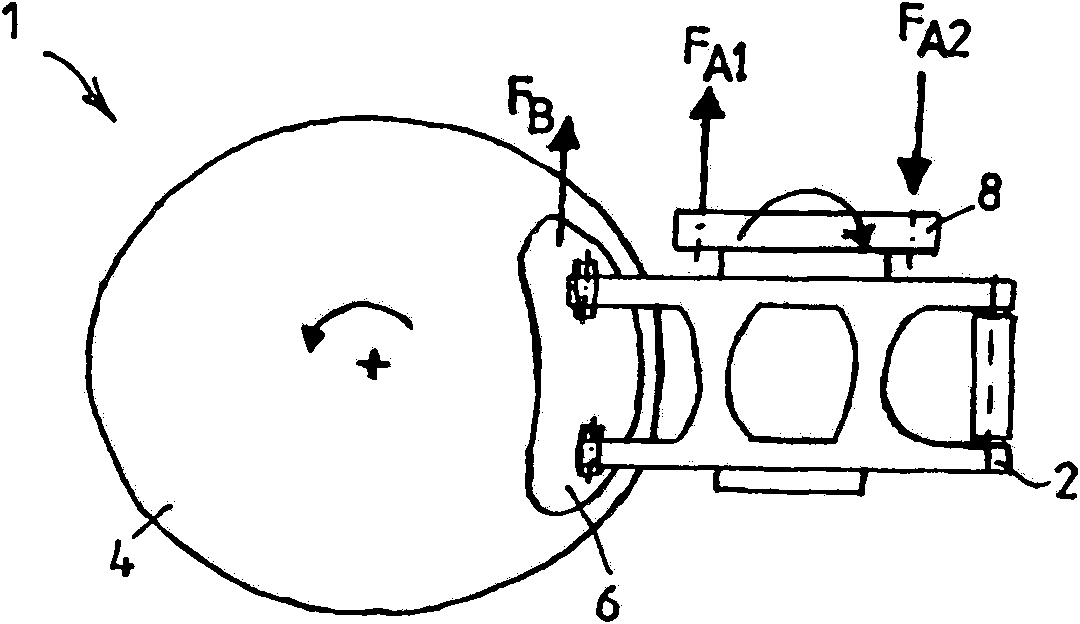

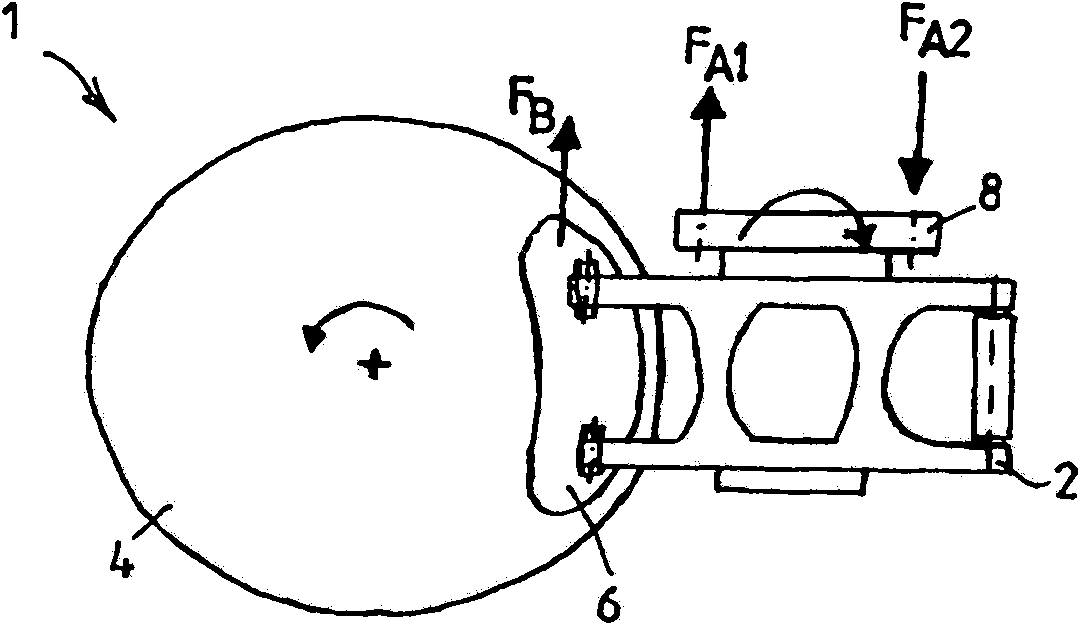

[0020] exist figure 1 A disc brake 1 for a rail vehicle according to a preferred embodiment of the invention is shown in , as is also known in principle, for example, from DE 10 245 207 C1 and is therefore only briefly described below.

[0021] The disc brake 1 comprises a brake caliper unit 2 as a brake actuator or brake application device, which has a service braking unit and an energy storage braking unit (not shown here). The brake caliper unit 2 comprises a brake disc 4 which cooperates with, for example, two brake linings 6 in a known manner, figure 1 Only one of the two brake linings is visible in the side view of the . The brake caliper unit 2 is preferably actuated pneumatically for generating a braking force F acting in the circumferential direction of the brake disc 4 according to the braking requirements B . Alternatively, it is of course also possible for the brake caliper unit 2 to be actuated with a pressure medium in another way, for example hydraulically or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com