Removal of crystallinity in guar based materials and related methods of hydration & subterranean applications

A guar gum, crystallization technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as incomplete removal of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

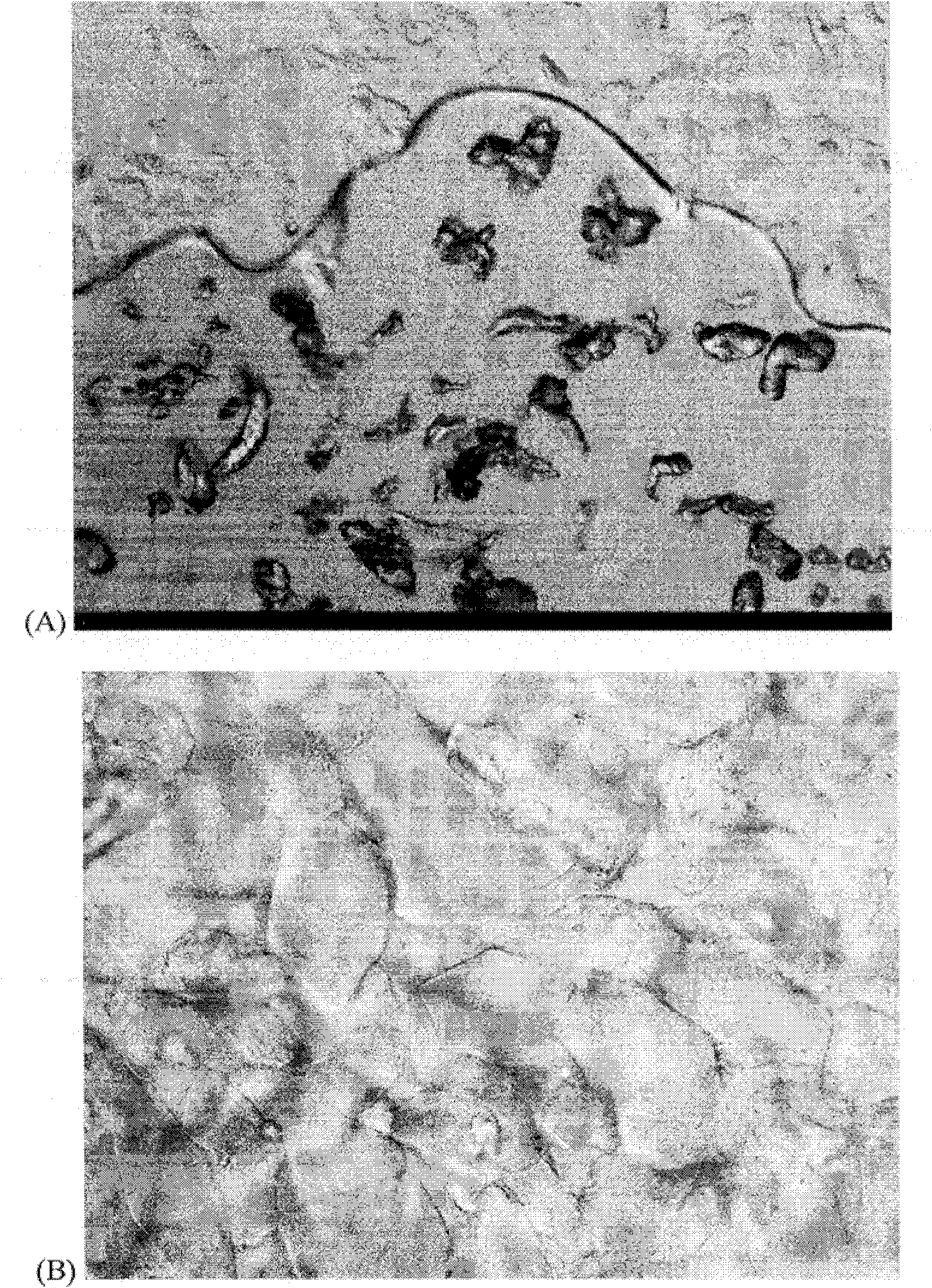

[0041] Of all the polymers examined, guar gum was found to be the most difficult to hydrate. under the microscope, as figure 1 As shown in , guar gum exhibits the degree of crystallinity shown in the lower part of (A). Even when in contact with water, the crystalline structure is not easily destroyed, as shown in the upper part of (A), where water has soaked the guar particles, but fragments of the guar particles can be seen. The guar gum particles will maintain its microdomains without completely dissolving in water.

[0042] exist figure 1 In, A and B are microscopic images of guar gum when in contact with water. (A) Guar powder dried (bottom) and partially exposed to water. (B) Guar gum in water in water emulsion with PEG8000, polyethylene glycol.

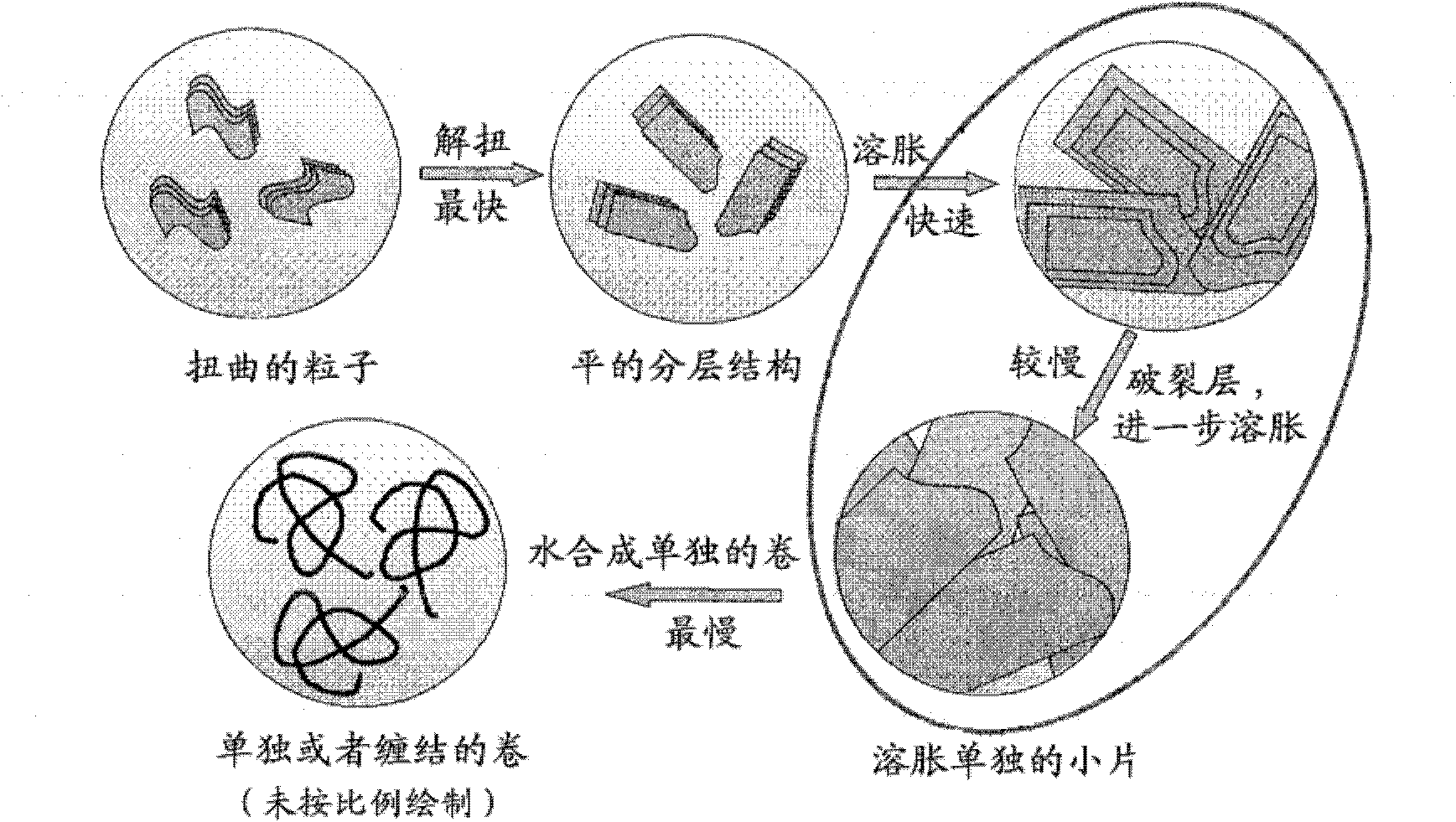

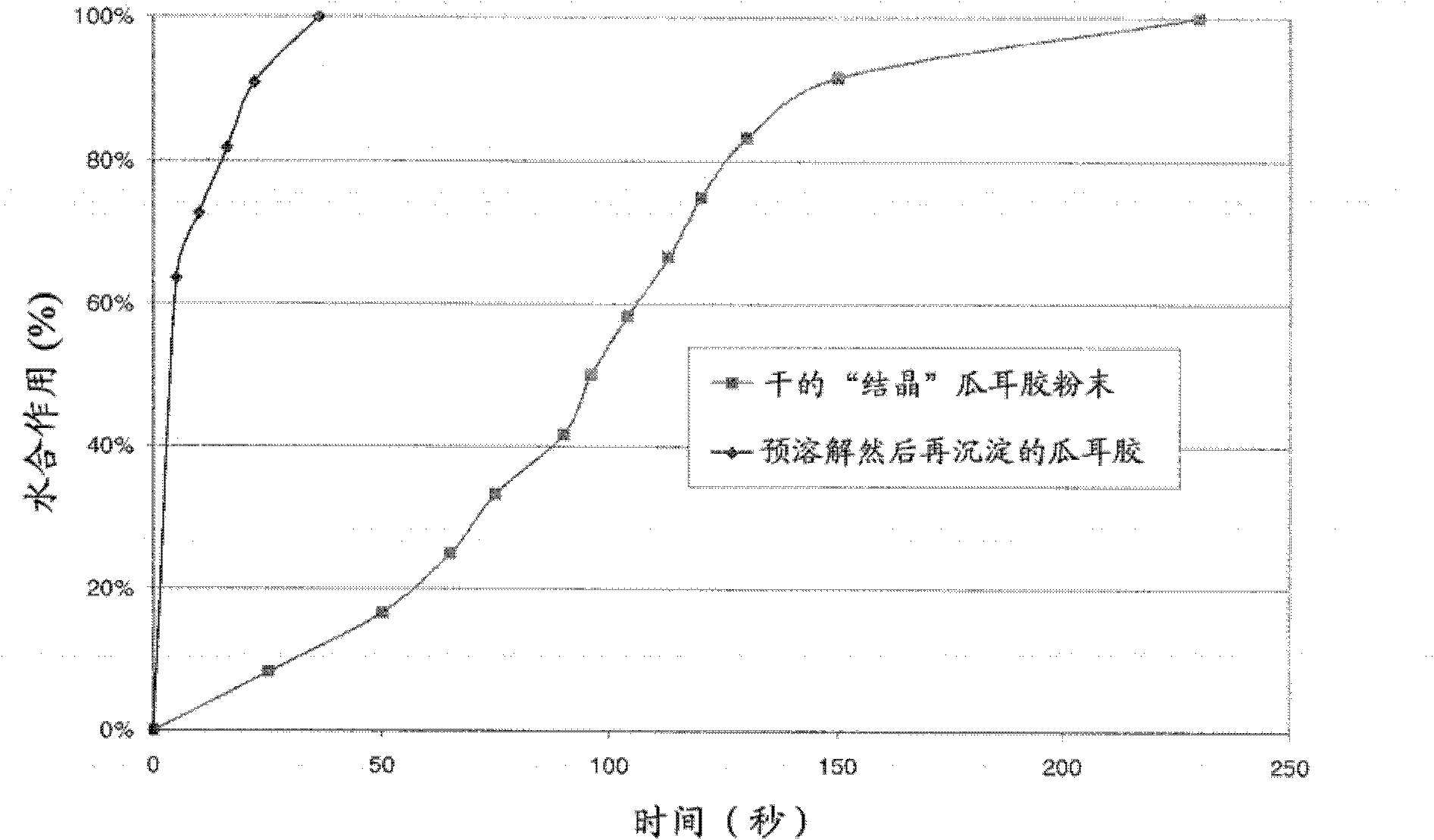

[0043] Closer examination of guar gum under a microscope reveals that its hydration begins with the rapid untwisting of initially twisted guar particles into a flat layered structure. The layers then swell rapidly, followe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com