Method for producing polarizing film

A manufacturing method and technology of polarizing film, which are applied in the directions of optics, polarizing elements, optical elements, etc., can solve the problem of insufficient polarizing performance of polarizing film, and achieve the effect of high polarizing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

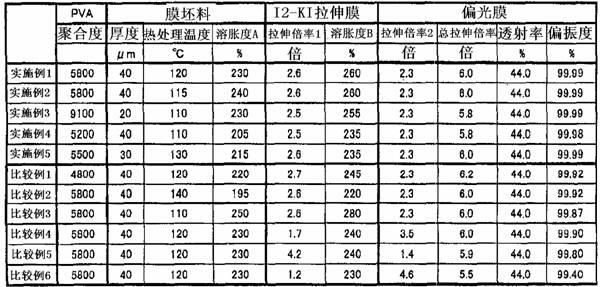

Examples

Embodiment 1

[0074] A 5.5% by mass PVA aqueous solution containing 100 parts by mass of PVA with a degree of polymerization of 5800 and a degree of saponification of 99.8 mol% and 12 parts by mass of glycerin as a plasticizer was cast on a metal roll at 60°C and dried for 60 minutes. A PVA film with a thickness of 40 μm was obtained. This film was fixed to a metal frame, and it heat-processed at 120 degreeC for 3 minutes. The degree of swelling A of the film material after heat treatment was measured by the method described in (2) above, and it was 230%.

[0075] Next, cut the above-mentioned film blank into a size of 11 cm in the flow direction × 10 cm in the width direction, take the flow direction as the stretching direction, install it on a stretching jig with a chuck distance of 4 cm, and immerse it in pure water at 30 ° C. After 1 minute, it was immersed in a dyeing solution (temperature 30° C.) containing 0.03 mass % iodine and 3 mass % potassium iodide, and stretched to 2.6 times ...

Embodiment 2

[0078] A 5.5% by mass PVA aqueous solution containing 100 parts by mass of PVA with a degree of polymerization of 5800 and a degree of saponification of 99.8 mol% and 12 parts by mass of glycerin as a plasticizer was cast on a metal roll at 60°C and dried for 60 minutes. A PVA film with a thickness of 40 μm was obtained. This film was fixed to a metal frame, and heat-processed at 115 degreeC for 3 minutes. The swelling degree A of the film material after heat treatment was measured by the method described in (2) above, and it was 240%.

[0079] Next, in the same manner as in Example 1, iodine was adsorbed while stretching the above-mentioned film raw material. The degree of swelling B of the obtained stretched film was measured by the method described in the above (3), and it was 260%.

[0080] Next, in the same manner as in Example 1, a polarizing film was obtained. The transmittance and polarization degree of the polarizing film were measured by the methods described in (...

Embodiment 3

[0082] A 5.5% by mass PVA aqueous solution containing 100 parts by mass of PVA with a degree of polymerization of 9100 and a degree of saponification of 99.8 mol% and 12 parts by mass of glycerin as a plasticizer was cast on a metal roll at 60°C and dried for 60 minutes. A PVA film with a thickness of 20 μm was obtained. This film was fixed to a metal frame, and it heat-processed at 110 degreeC for 3 minutes. The degree of swelling A of the film material after heat treatment was measured by the method described in (2) above, and it was 230%.

[0083] Next, iodine was adsorb|sucked, stretching the said film raw material similarly to Example 1 except having made stretching ratio into 2.5 times. The degree of swelling B of the obtained stretched film was measured by the method described in the above (3), and it was 255%.

[0084] Next, in the same manner as in Example 1, a polarizing film was obtained. The transmittance and polarization degree of the polarizing film were measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| degree of polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com