Rotation type multi-station thermal transfer printing machine

A thermal transfer machine, multi-station technology, used in rotary printing machines, printing machines, transfer printing and other directions, can solve the problem of affecting product appearance quality and market value, long time for hot sol to fully melt, and strong pattern adhesion. Insufficient degree of temperature and other problems, to shorten the melting time, improve the surface quality and market value, the structure is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

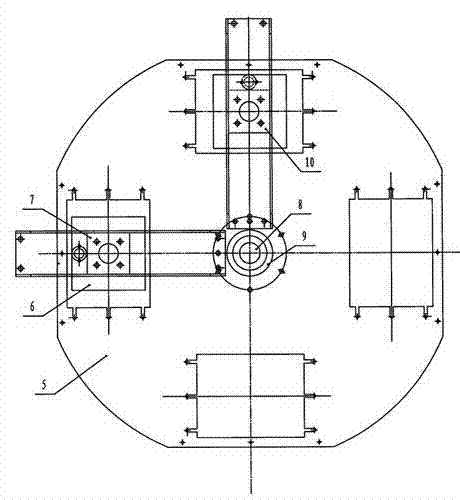

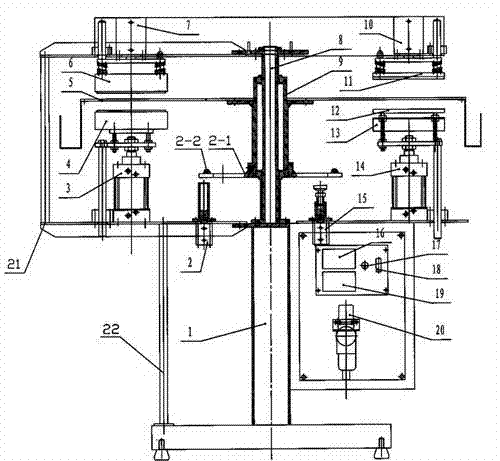

[0016] Such as Figure 1~2 As shown, 1 in the figure is a frame, a rotating main shaft 8 is vertically arranged at the central position of the frame 1, a rotating hoist head 9 is arranged around the rotating main shaft 8, and a rotating hoist head 9 is horizontally arranged on the top of the rotating hoist head 9. The working disk 5 is horizontally provided with a rotary positioning disc 2-1 at the lower part of the rotating hoist head, and two proximity switches 2-2 are arranged at the lower part of the upper edge of the rotary positioning disc 2-1, and two proximity switches 2-2 are arranged at the lower part of the edge of the rotary positioning disc. There are also four positioning bosses evenly distributed, and the frame corresponding to the proximity switch is also provided with a positioning pin cylinder 2 and a locking cylinder 15; the heat transfer mechanism includes: Between the 5, a lower cylinder 3 and a lower electric heating plate 4 are sequentially arranged, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com