Vertical resistance belt fast heating furnace

A rapid heating and resistance band technology, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of insufficient heating layer depth, large floor space, and high investment, and achieve simple structure, small floor space, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

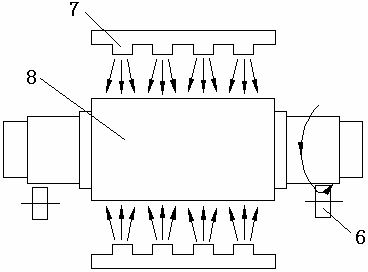

[0034] 2 pieces of back-up roll dimensions such as Figure 7 As shown, the diameter of the roll body is Φ1280mm, the length of the roll body is L 1350mm, and the weight of a single piece is 20.47 tons for surface quenching of the roll body. The backup roll material is 70Cr3Mo steel, the actual quenched size of the roll body is Φ1283mm, the length is 1360mm, the diameter is 3mm for grinding allowance, and the length is 10mm for machining allowance. The hardness of the roll body requires HS 65~70. The depth of the hardened layer is ≥45mm, and the hardness uniformity HS≤3.

[0035] The hearth diameter D of the rapid heating furnace used for surface quenching this time is 2.6 meters, and the height H of the furnace body is 2.0 meters. Figure 8 For this heat treatment process curve, the first preheating temperature of the backup roll is 300°C for 8 hours, and the second preheating temperature is 550°C for 20 hours. Rapid heating is from 550°C to 900°C, and the heating rate is 90...

Embodiment 2

[0038] 2 pieces of back-up roll dimensions such as Figure 9 shown. The diameter of the roll body is Φ752, the length of the roll body is 1690, and the weight of a single piece is 7.5 tons. The backup roller material is 9Cr2Mo steel. The hardness of the roll body requires HS 75-80. Hardened layer depth ≥ 30mm, hardness uniformity HS ≤ 3.

[0039] The hearth diameter D of the rapid heating furnace used for surface quenching this time is 2.60 meters, and the height H of the furnace body is 2.00 meters. Figure 10 For the process curve of this heat treatment, the preheating temperature of the backup roll is 300°C for 5 hours and 540°C for 10 hours. Rapid heating is from 540°C to 900°C, and the heating rate is 100°C / hour. After the surface of the roller reaches 900°C, it is kept warm for 1.5 hours. Then it is quenched. After quenching, it is tempered at 320°C, and after 80 hours of heat preservation, the furnace is cooled to 150°C and released.

[0040] After inspection, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com