Five-lobe micro-hole spinneret

A spinneret and microporous technology, applied in filament/thread forming, textile and papermaking, fiber treatment, etc., can solve the problems of fabric moisture absorption and air permeability that cannot meet market demand, so as to improve product quality and production speed, High value-added, good feel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

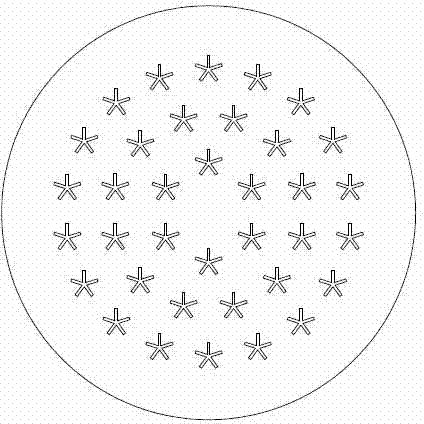

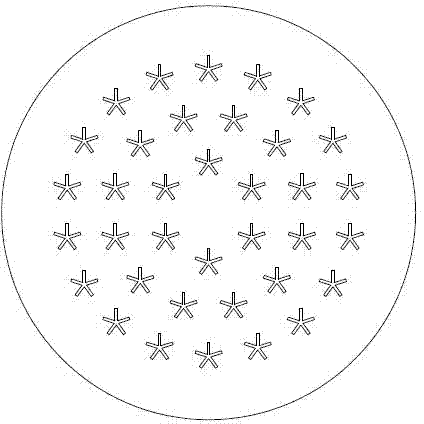

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A five-lobed microporous spinneret, comprising a spinneret and a spinneret hole, the spinneret has 30-40 spinneret holes, the shape of the spinneret holes is five-lobed, and the The interval is , the leaf width of the five leaves of the spinneret hole is 0.08-0.12mm, the leaf length is 0.30-0.60mm, and the leaf hole height is 0.60-0.80mm, and the spinneret hole is divided into three circles on the spinneret plate evenly arrangement.

[0014] During specific use, the number of spinneret holes and the length, width and height of the spinneret holes of the present invention can be determined according to actual needs. Such as figure 1 As shown, the number of spinneret holes of the present invention is preferably 36, arranged in three circles, from the innermost layer, the first circle is 6, the second circle is 12, and the third circle is 18; The leaf lengths ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leaf width | aaaaa | aaaaa |

| Ye chang | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com