Automatic lubricating system of excavator

An automatic lubrication and excavator technology, applied in the field of lubrication systems, can solve the problems of easy separation of grease, large system pressure loss, low degree of automation, etc., to reduce the possibility of line blockage, increase the system pressure maintaining stage, and the degree of automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with principle diagrams and specific operation examples.

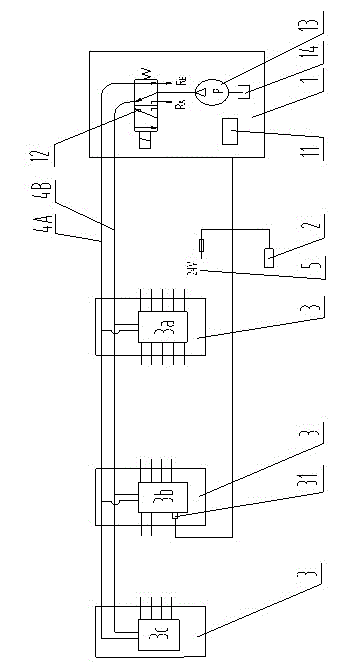

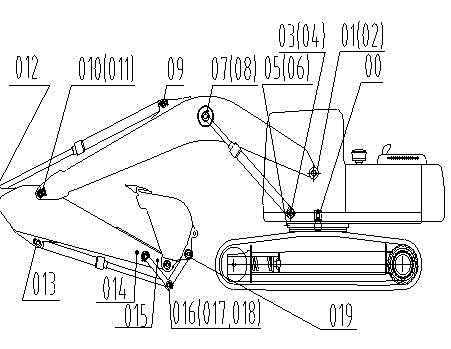

[0022] Such as figure 1 As shown, the automatic lubrication system of the excavator of the present invention includes: a pump unit 1, a display unit 2 and a distributor unit 3, the pump unit 1 is located at the rear of the upper frame of the excavator, and includes a control unit 11, a two-position five-way solenoid valve 12, The electric plunger pump 13 and the oil storage tank 14, the two-position five-way solenoid valve 12 is connected with the control unit 11, one end of the electric plunger pump 13 is connected with the oil storage tank 14, and the other end is connected with the control unit 11, from the pump unit 1 Two main lubricating lines 4A, 4B are led out, and the oil storage tank 14 communicates with the two main lubricating lines 4A, 4B through the two-position five-way solenoid valve 12, and the two main lubricating lines 4A, 4B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com