Swirl side suction oil pump

A technology for oil suction pumps and oil well pumps, which is applied to pumps, pumps with flexible working elements, liquid displacement machinery, etc. It can solve the problems of piston fixed valve fixed valve ball seat piercing and increased mining difficulty, etc., to achieve pump The effect of small external diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

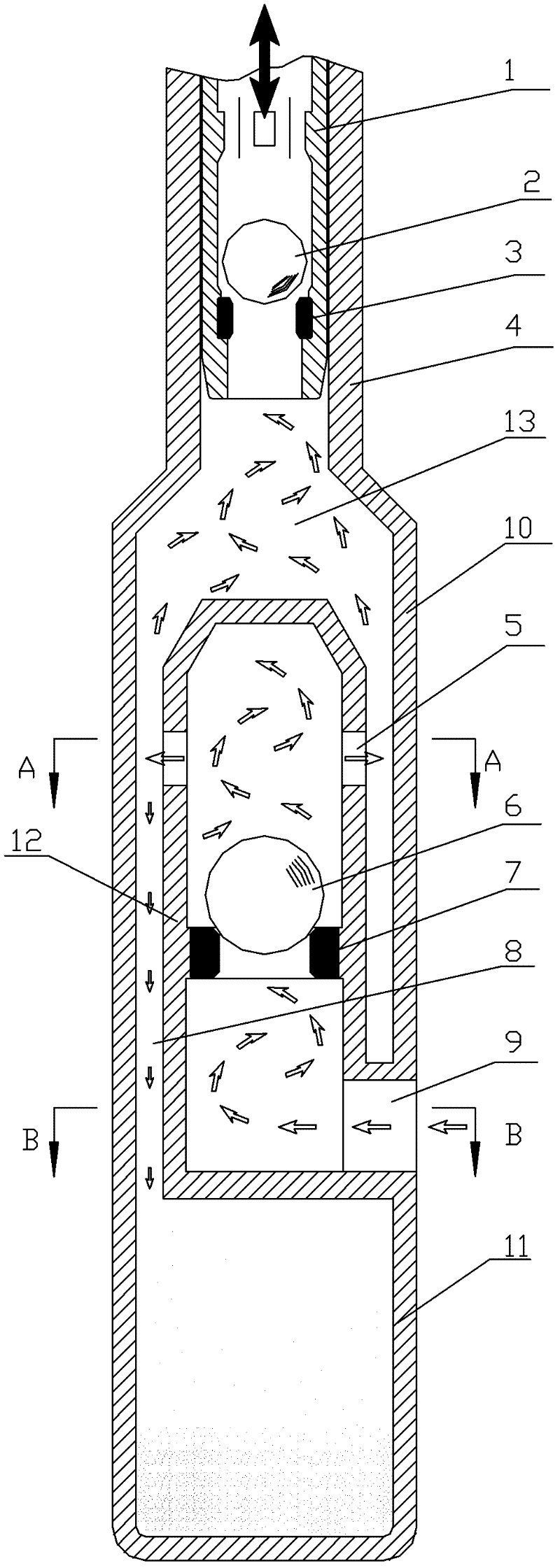

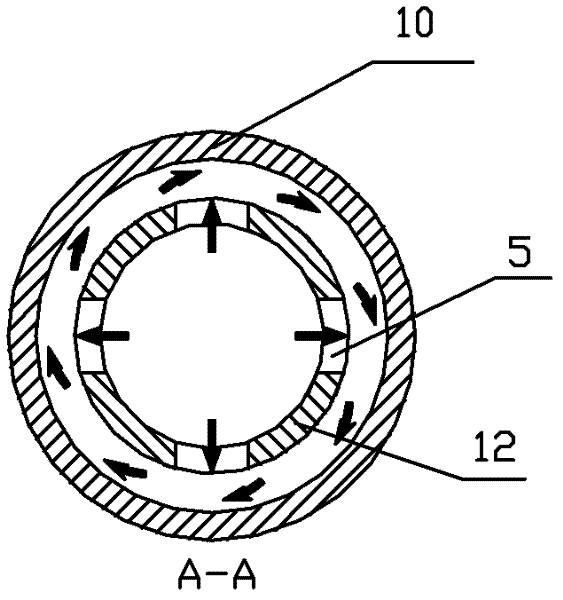

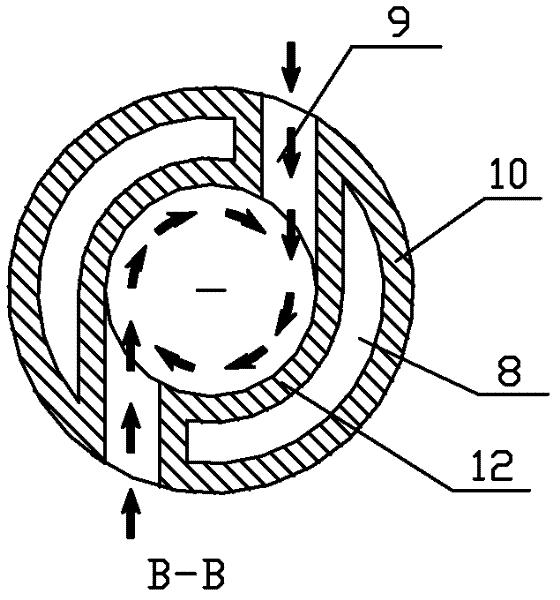

[0017] figure 1 It is a structural schematic diagram of an embodiment of the present invention, figure 2 for figure 1 A-A sectional view of, image 3 for figure 1 The B-B sectional view of B-B includes a suction oil pump, the lower end of the suction oil pump is connected with a cyclone separation cylinder, and the lower end of the cyclone separation cylinder is connected with the grit chamber 11, and the cyclone separation cylinder includes an outer cylinder 10 and an inner cylinder 12, The outer cylinder 10 is connected with the suction oil pump and the grit chamber 11 respectively. The inner cylinder 12 is installed in the inner cavity of the outer cylinder 10 and is isolated from the inner cavity of the outer cylinder as a whole, so that the circumference between the outer circumference of the inner cylinder and the inner cavity of the outer cylinder An annular flow channel 8 and an oil chamber 13 are formed to and above, and a tangential oil inlet hole 9 communicating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com