Detection device and detection method for dynamic process of material micro-domain structure change

A technology of structural change and process detection, which is applied in the field of optical detection, can solve the problems that the focal length of the lens cannot be too short, the numerical aperture objective lens cannot be used, and the large space, etc., and achieve the effect of high repeatability, less human error, and accurate detection position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

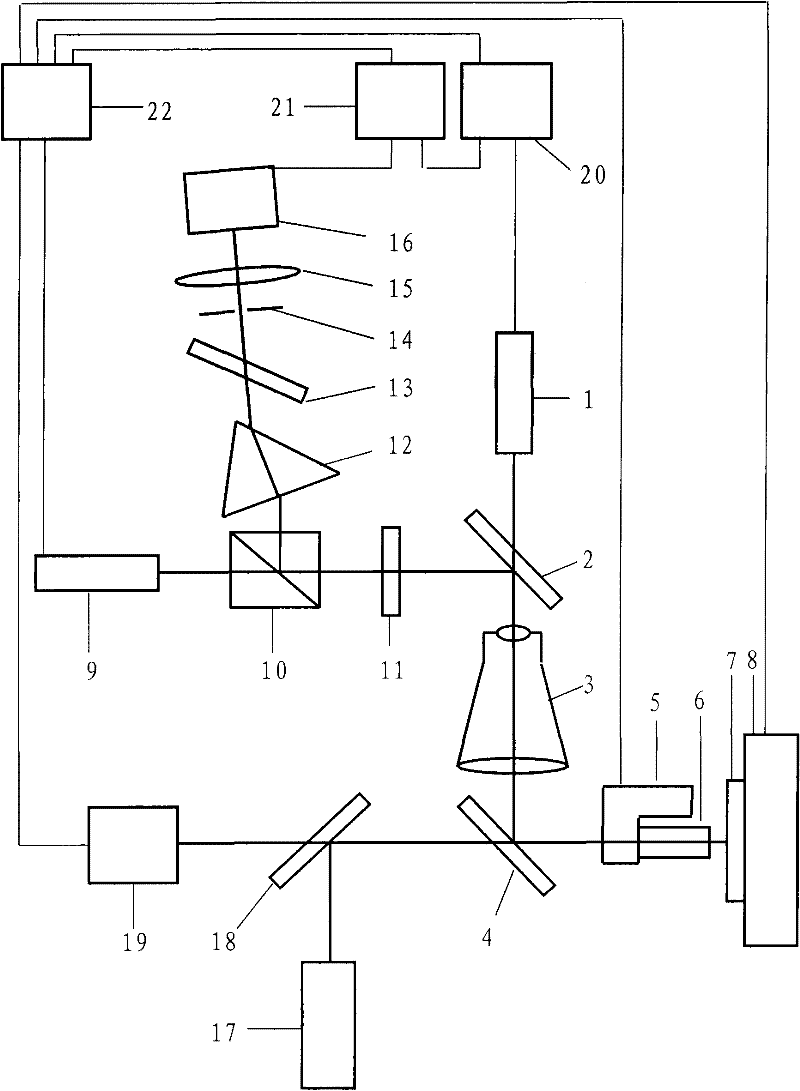

[0043] figure 1 It is an optical path structure diagram of an embodiment of the detection device for the dynamic process of material micro-region structure change realized by the present invention. Such as figure 1 As shown, the detection device for the dynamic process of the material micro-domain structure change includes three parts: the first part is the part where the laser-induced material micro-domain changes, the second part is the part that detects the dynamic process of the material micro-domain structure change, and the third part It is the CCD observation part.

[0044] The part where the laser-induced material micro-domain changes: on its main optical axis, the output laser wavelength λ is sequentially included 1 The first laser device 1, the first spectral beam splitter 2, the beam expander 3, and the second spectral beam splitter 4, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com