Liquid crystal display device and manufacturing method thereof

A technology of a liquid crystal display device and a manufacturing method, which is applied to static indicators, optics, instruments, etc., and can solve problems such as thickness occupied by conductive adhesive tape, narrow frame design troubles, and light leakage of the plane conversion liquid crystal display device 300, so as to facilitate thinning , reduced design, reduced width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

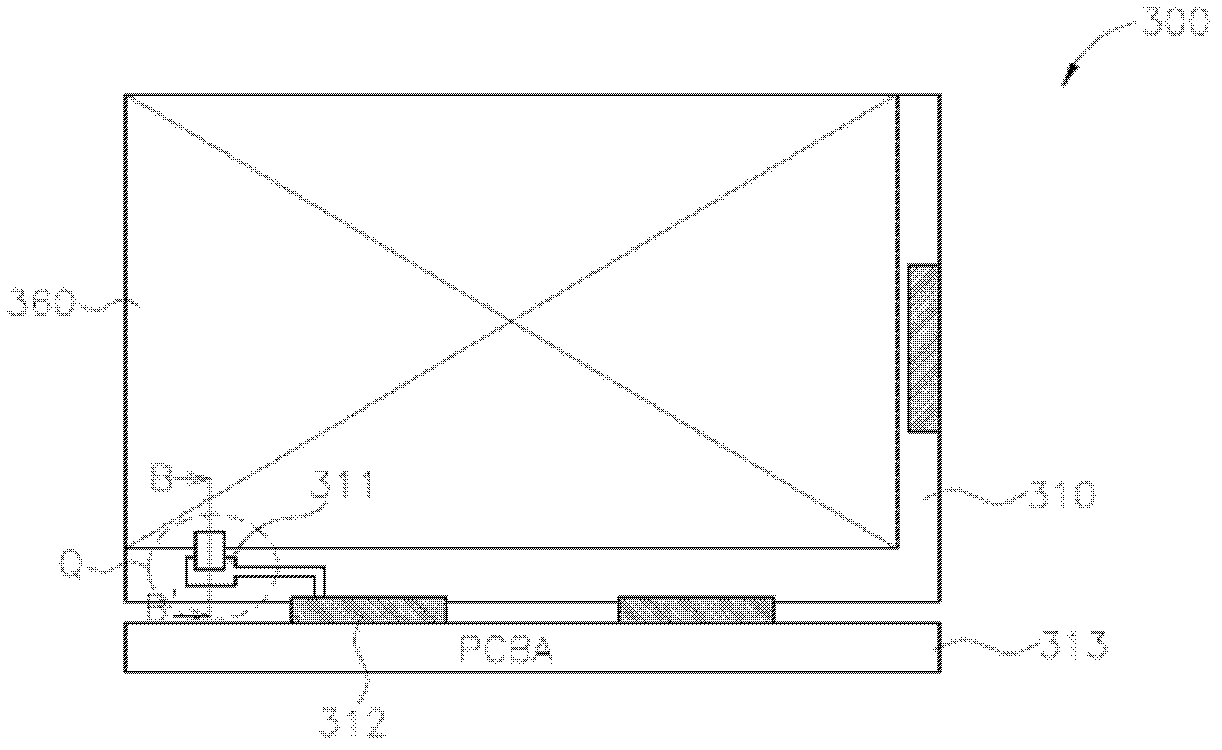

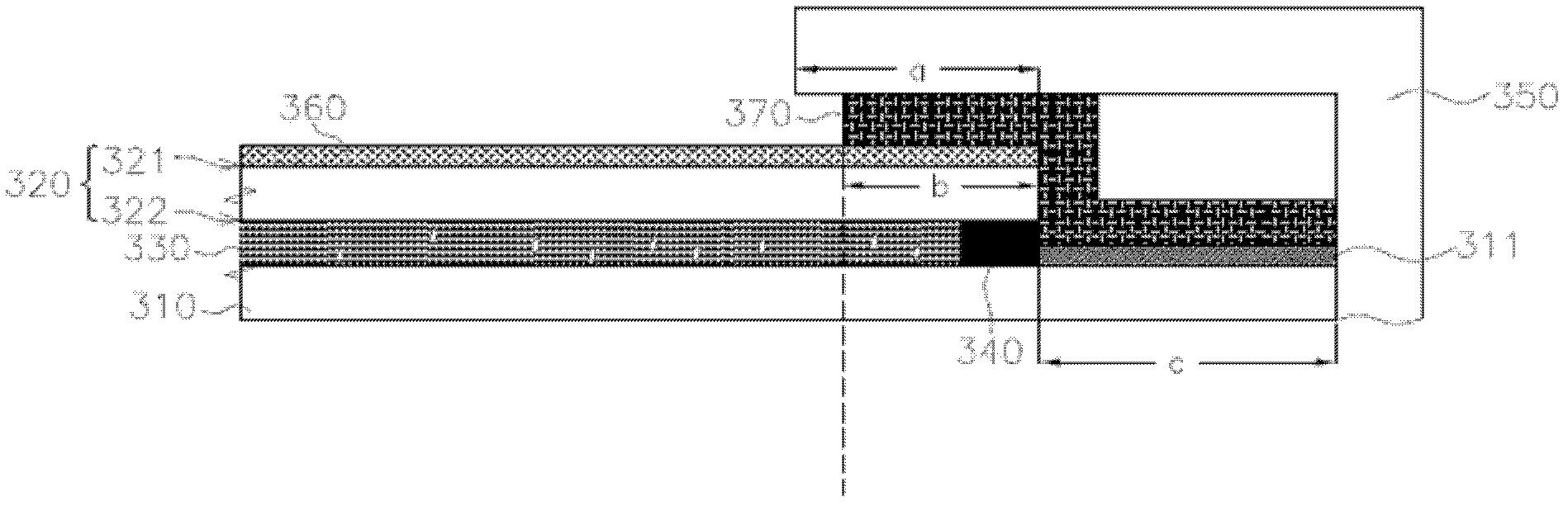

[0048] Figure 5 It is a top view of the plane switching liquid crystal display device according to the first embodiment of the present invention, Image 6 is a perspective view of the plane switching liquid crystal display device of the first embodiment of the present invention, first, as Figure 5 and Image 6 As shown, the plane switching liquid crystal display device 400 includes a first substrate 410, a second substrate 420, a conductive metal layer 411, an electromagnetic shielding layer 460, a flexible printed circuit substrate 412 and a printed circuit board assembly 413, wherein the The second substrate 420 is arranged on the first substrate 410 and the two are oppositely arranged, and a conductive metal layer 411 is arranged on the first substrate 410, and the conductive metal layer 411 of the second substrate 420 and the first substrate 410 Covered with an electromagnetic shielding layer 460, and the electromagnetic shielding layer 460 is electrically connected to...

no. 2 example

[0064] Figure 10 It is a top view of the plane switching liquid crystal display device according to the second embodiment of the present invention, Figure 11 It is a perspective view of a plane switching liquid crystal display device according to the second embodiment of the present invention, Figure 12 yes Figure 10 A schematic cross-sectional view of a plane-switching liquid crystal display device along line DD'. The plane-switching liquid crystal display device of this embodiment is similar to the plane-switching liquid crystal display device of the first embodiment. Therefore, the same component symbols represent the same components. The difference between this embodiment and the first embodiment is the design of the second substrate and the electromagnetic shielding layer.

[0065] Please merge reference Figure 10 , Figure 11 and Figure 12 , the second substrate 520 includes an upper surface 521 and a lower surface 522, wherein the upper surface 521 is the sur...

no. 3 example

[0077] Figure 14 It is a top view of the plane switching liquid crystal display device of the third embodiment of the present invention, Figure 15 It is a perspective view of a plane switching liquid crystal display device according to the third embodiment of the present invention, Figure 16 yes Figure 14 A schematic cross-sectional view of a plane-switching liquid crystal display device along line EE'. The plane-switching liquid crystal display device of this embodiment is similar to the plane-switching liquid crystal display device of the first embodiment, and the same component symbols represent the same components. The difference between this embodiment and the first embodiment lies in the design of the electromagnetic shielding layer and the addition of an auxiliary part.

[0078] Please refer to Figure 14 , Figure 15 and Figure 16 , in this embodiment, the plane switching liquid crystal display device 600 further includes an auxiliary part 690, the auxiliary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com