Frameless panel manufacturing method and product thereof

A manufacturing method and frameless technology, applied in the direction of instruments, identification devices, etc., can solve the problems of framed panel visual defects, limited visual area, complicated process, etc., to enhance visual comfort, simplify the manufacturing process, thickness thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

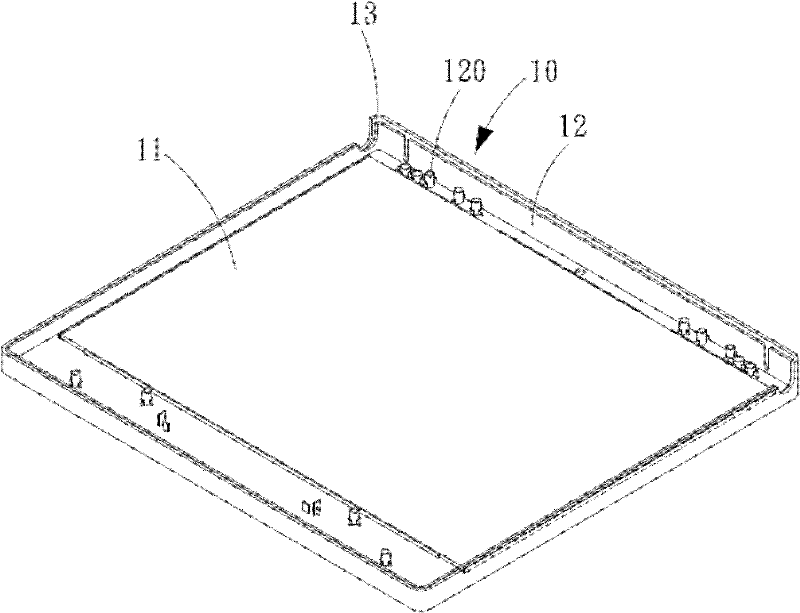

Image

Examples

Embodiment Construction

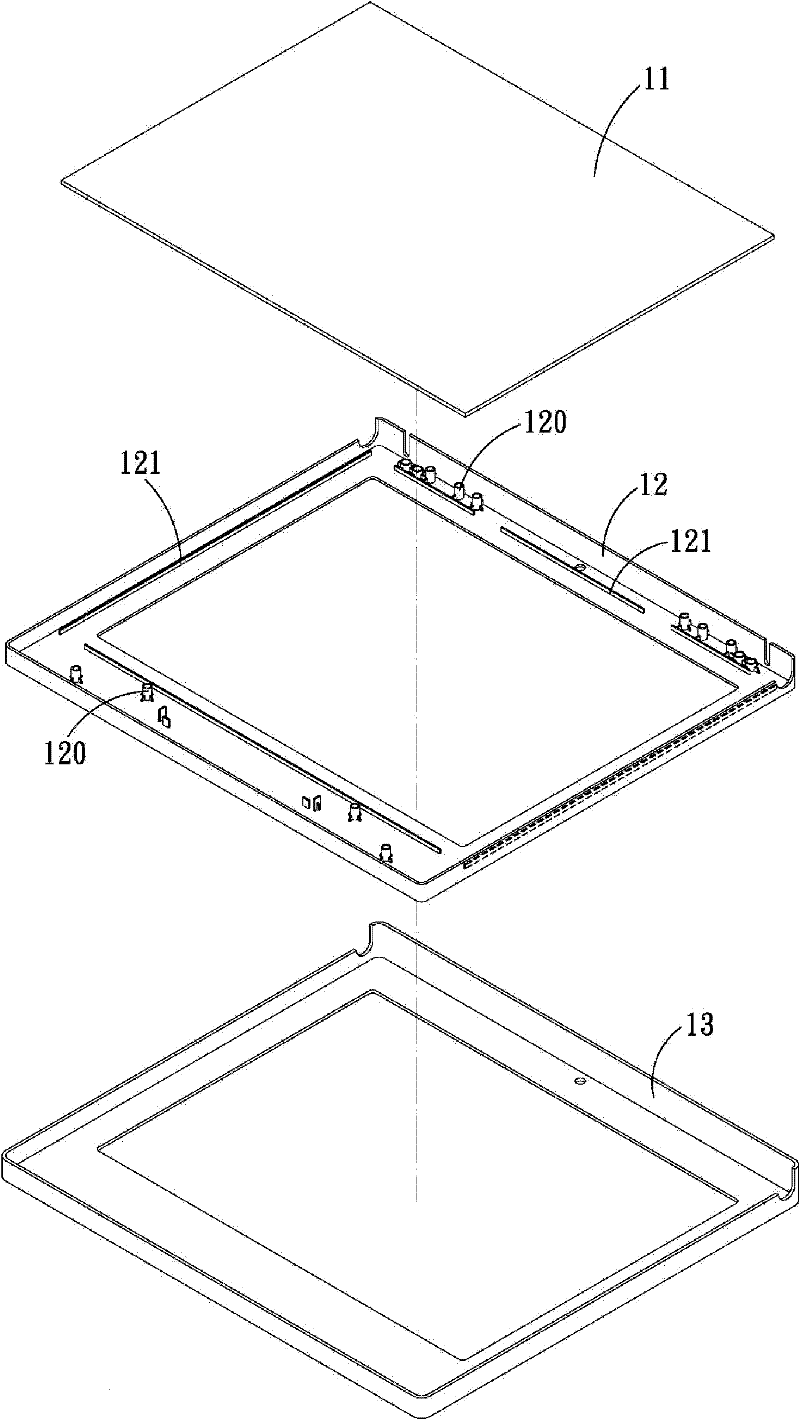

[0044] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

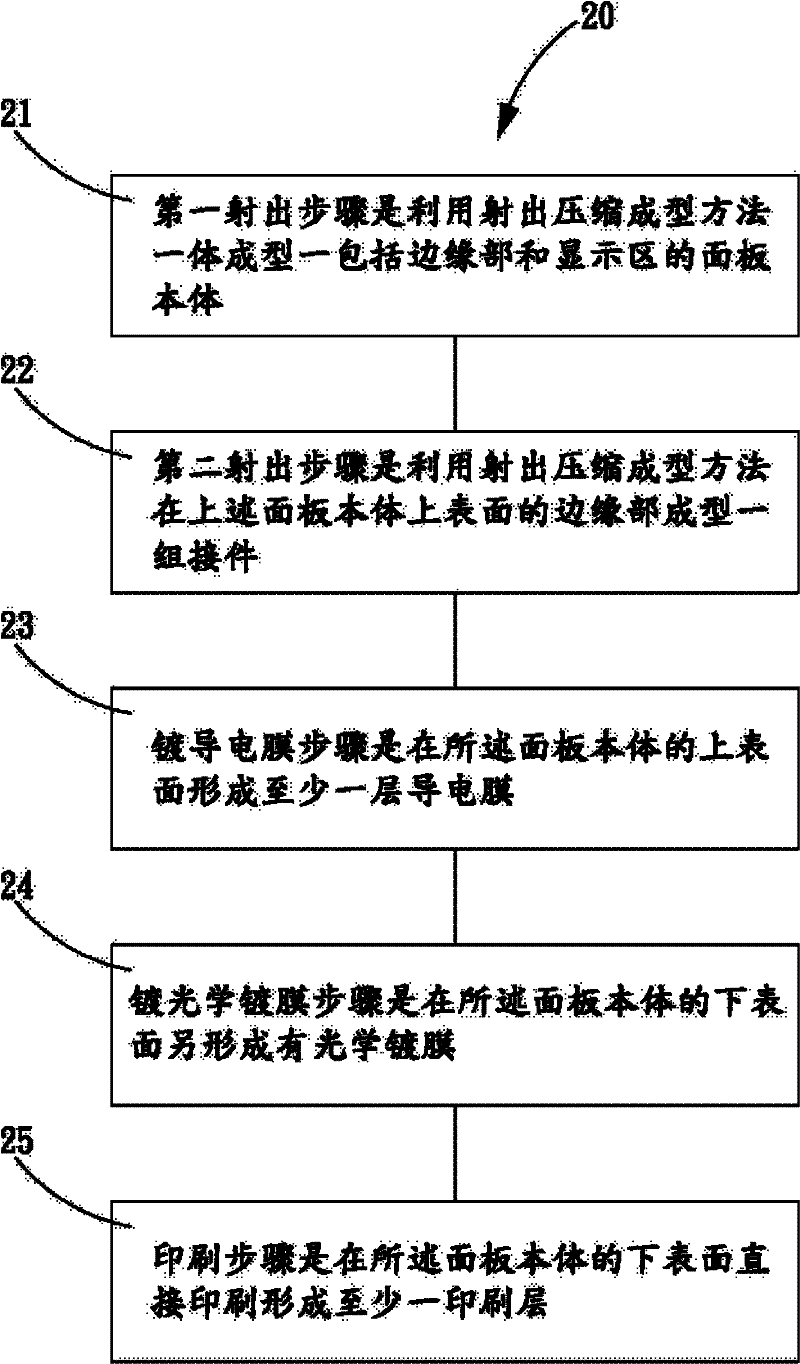

[0045] see image 3 As shown, the frameless panel manufacturing method 20 applied to the touch panel field mainly includes the following steps:

[0046] A first injection step 21 is to use the injection compression molding method to integrally form a transparent panel body including the edge part and the display area. The edge portion of the utility model has a hemming type, or other structural forms that meet practical requirements.

[0047] A second injection step 22 is to use the injection compression molding method to form a joint on the edge of the upper surface of the panel body, and the joint is used for the assembly of the panel body and the display component;

[0048] A conductive film plating step 23 is to form at least one conductive film on the upper ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap