muscle enhancer

A technology of enhancer and muscle, applied in the field of muscle enhancer, can solve the problems of reduced yield, unachievable antigenicity, reduced yield, etc., and achieves the effect of easy production and economical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Papain (50 U / g whey protein) and Proleather (manufactured by Amano Enzyme Inc.) (150 U / g whey protein) were added to 1 liter of 10% whey protein aqueous solution. After adjusting the pH of the mixture to 8, the whey protein was hydrolyzed and denatured at 55°C for 6 hours. The reaction solution was heated at 100° C. for more than 15 seconds to inactivate the protease. The reaction solution was then centrifuged, and the supernatant was collected. The supernatant was then dried to obtain whey protein hydrolyzate.

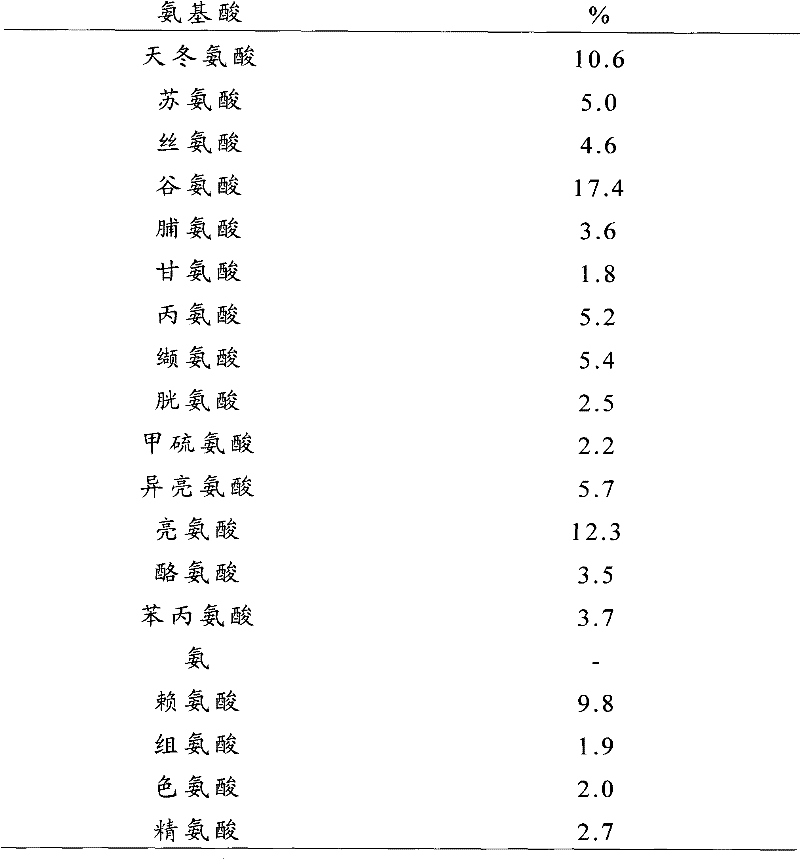

[0052] The obtained whey protein hydrolyzate has a molecular weight distribution below 10 kDa, a main peak of 1.3 kDa, an APL of 7.2 and a free amino acid content of 18.9% of all components.

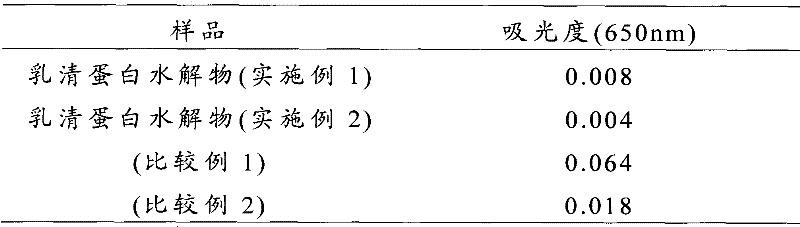

[0053] The whey protein hydrolyzate has an antigenicity equal to or less than 1 / 100,000 that of β-lactoglobulin (measured by inhibition ELISA). The yield (ie, the ratio (%) of the dry weight of the supernatant obtained by centrifuging the enzyme reaction solution to th...

Embodiment 2

[0060] Papain (50 U / g whey protein) and Proleather (150 U / g whey protein) were added to 1 liter of 10% whey protein aqueous solution. After adjusting the pH of the mixture to 8, the whey protein was hydrolyzed at 50°C for 3 hours. The mixture was heated to 55°C where the whey protein was denatured and hydrolyzed for 3 hours. The mixture was then heated at 100°C for more than 15 seconds to inactivate the protease. The reaction solution was filtered using a UF membrane (manufactured by STC) with a molecular weight cut-off of 10 kDa and an MF membrane (manufactured by STC) with a molecular weight cut-off of 300 Da to collect a concentrate fraction. The fractions are then dried to obtain whey protein hydrolyzate.

[0061] The obtained whey protein hydrolyzate has a molecular weight distribution below 10kDa, a main peak of 500Da, an APL of 3.0 and a free amino acid content of 15.2% of all components.

[0062] The whey protein hydrolyzate has an antigenicity (measured by inhibiti...

Embodiment 3

[0090] Preparation of nutritional composition for muscle enhancement

[0091]50 g of the whey protein hydrolyzate obtained in Example 2 was dissolved in 4950 g of deionized water. The solution was heated to 50° C. and stirred at 6000 rpm for 30 minutes using a TK homomixer (“TKROBOMICS” manufactured by PRIMIX Corporation) to obtain a whey protein hydrolyzate solution (whey protein hydrolyzate content: 50 g / 5 kg) . 5.0kg casein, 5.0kg soybean protein, 1.0kg fish oil, 3.0kg perilla (perilla) oil, 18.0kg dextrin, 6.0kg mineral mixture, 1.95kg vitamin mixture, 2.0kg emulsifier, 4.0kg stabilizer and 0.05 kg of aroma compounds were added to 5.0 kg of whey protein hydrolyzate solution. A retort pouch (200ml) was filled with the mixture. The mixture was then sterilized at 121° C. for 20 minutes using an autoclave (a type of pressure vessel, “RCS-4CRTGN”, manufactured by Hisaka Works, Ltd.) to produce 50 kg of the nutritional composition for muscle strengthening of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com