Patents

Literature

32results about How to "Synthesis Yield Increased" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

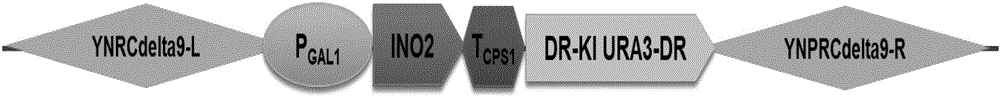

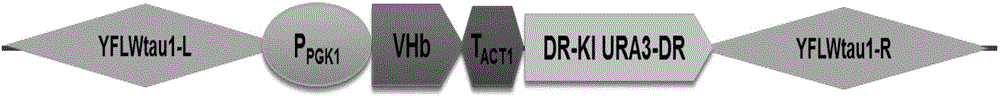

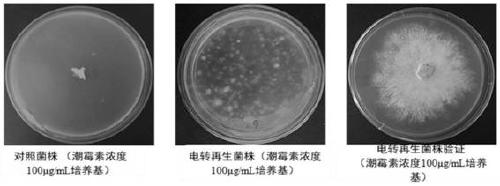

Recombinant yeast strain, construction method and application thereof

The invention relates to the technical field of gene engineering, and discloses a recombinant yeast strain, a construction method thereof and the application thereof. In the recombinant yeast strain, gal1, gal7, gal10 and ypl062w genes are knocked out, and the recombinant yeast strain comprises 6 gene segments which are integrated to the genome through yeast homologous recombination. On the above basis, the recombinant yeast strain is further integrated onto one gene segment of a yeast genome, so that a better recombinant yeast is obtained. According to the technical scheme of the invention, the yeast strain is constructed based on gene knock-out, and an optimized host cell for producing lycopene is provided. Meanwhile, functional genes crtE crtB and crtI of a specific source combination and used for the synthesis of lycopene, specific yeast endogenous genes and specific exogenous genes are selected. The above selected genes are integrated to the gene knock-out genome of the yeast strain, and then a brand-new recombinant strain capable of producing high-yield lycopene is obtained.

Owner:TIANJIN UNIV

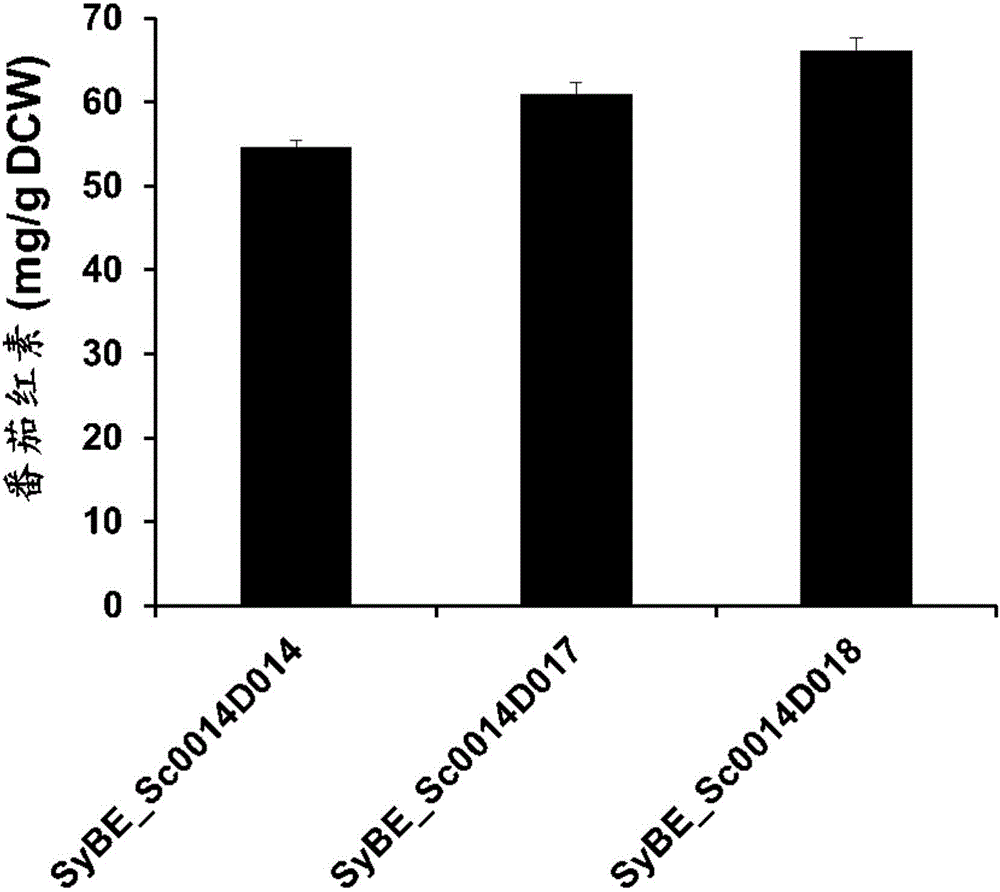

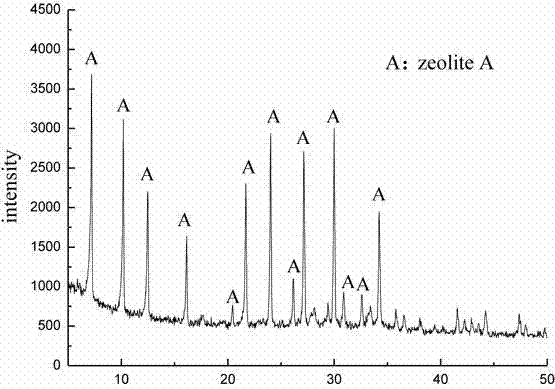

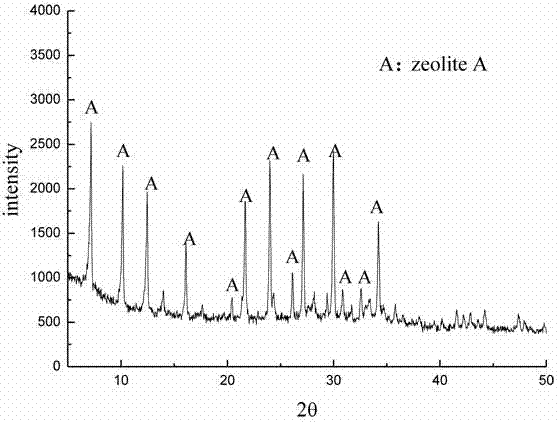

A method for synthesizing two different grades of A-type zeolites by utilizing coal ashes

InactiveCN104843735AHigh puritySynthesis Yield IncreasedSolid waste disposalAluminosilicate zeolite type-AResource utilizationAdditive ingredient

The invention relates to a method for synthesizing two different grades of A-type zeolites by utilizing coal ashes. The method is characterized by using the coal ashes as raw material, carrying out pretreatment on the coal ashes, and then, fusing the coal ashes and sodium carbonate under a high temperature; mixing the coal ashes obtained after alkali fusion with water fully to dissolve out sodium silicate, silicon-aluminum ratio in the ingredients of the desiliconized coal ashes being ideal ratio for synthesizing the A-type zeolites; then, mixing and stirring the desiliconized coal ashes and a sodium hydroxide solution to obtain a silica-alumina gel; carrying out hydrothermal crystallization on the silica-alumina gel, carrying out washing till the pH value is neutral after the crystallization, and carrying out drying to obtain a type-I A-type zeolite; adding appropriate amount of sodium aluminate into desiliconized filtrate, wherein the desiliconized filtrate is a solution comprising the sodium silicate; and carrying out hydrothermal crystallization, washing and drying to obtain a type-II A-type zeolite. The method can enable effective constituents of aluminosilicate in the coal ashes to be used completely, and is an effective resource utilization mode.

Owner:SOUTHWEAT UNIV OF SCI & TECH

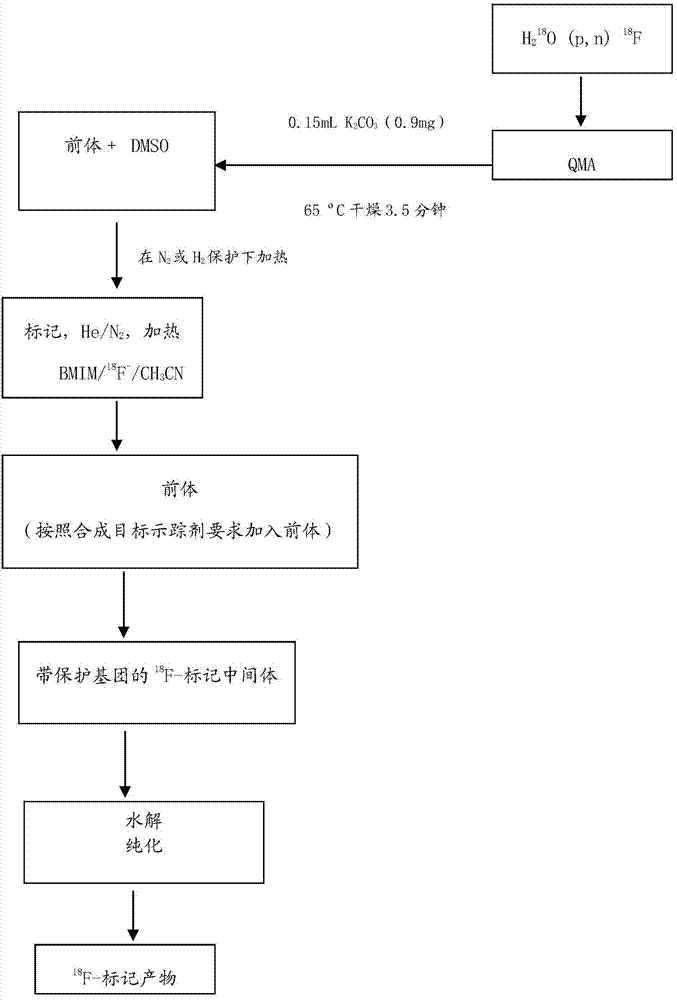

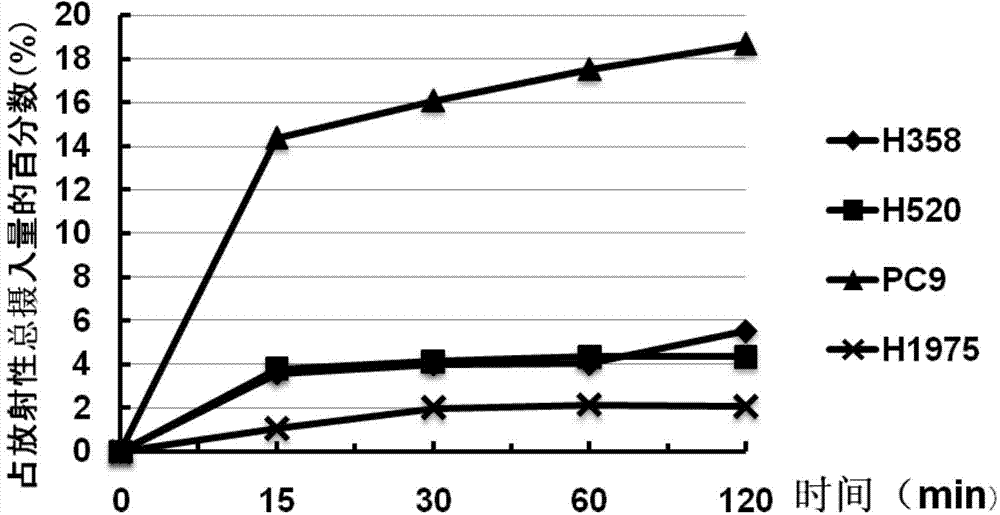

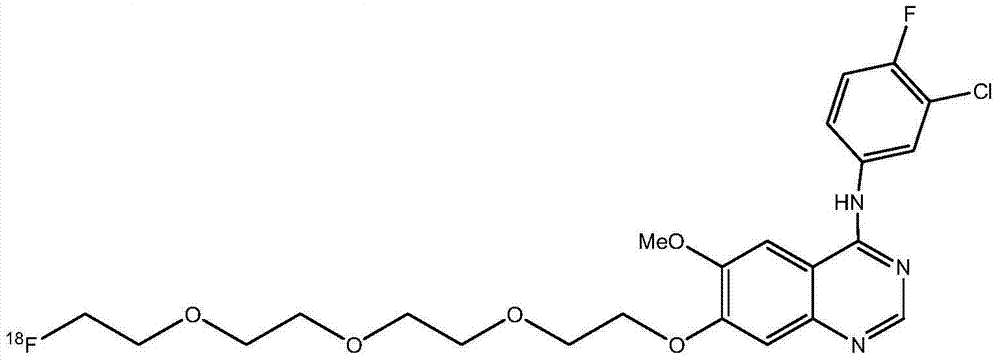

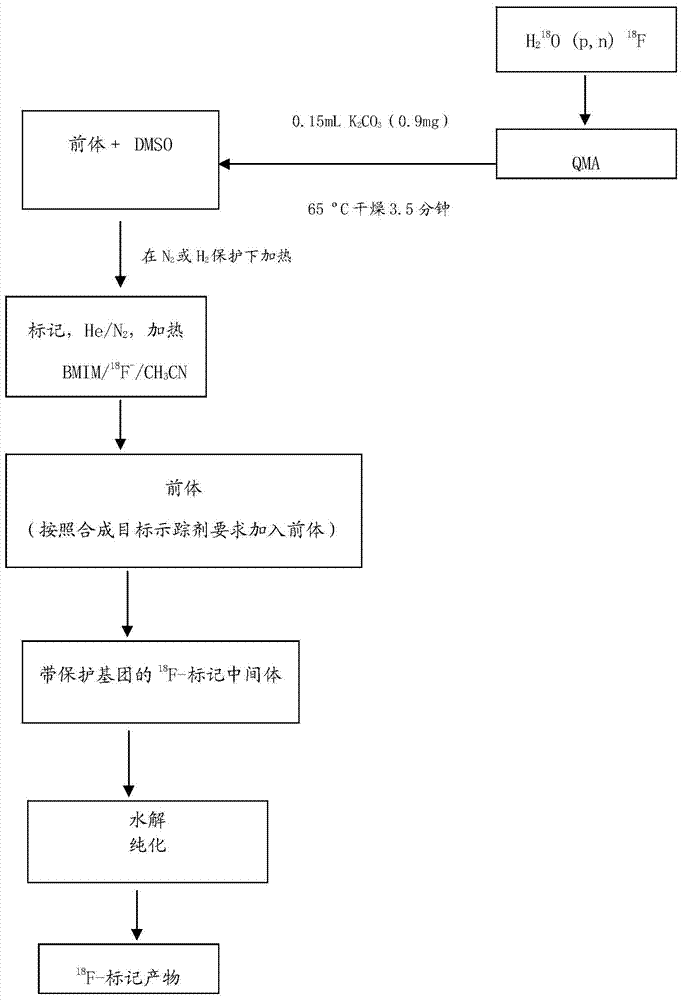

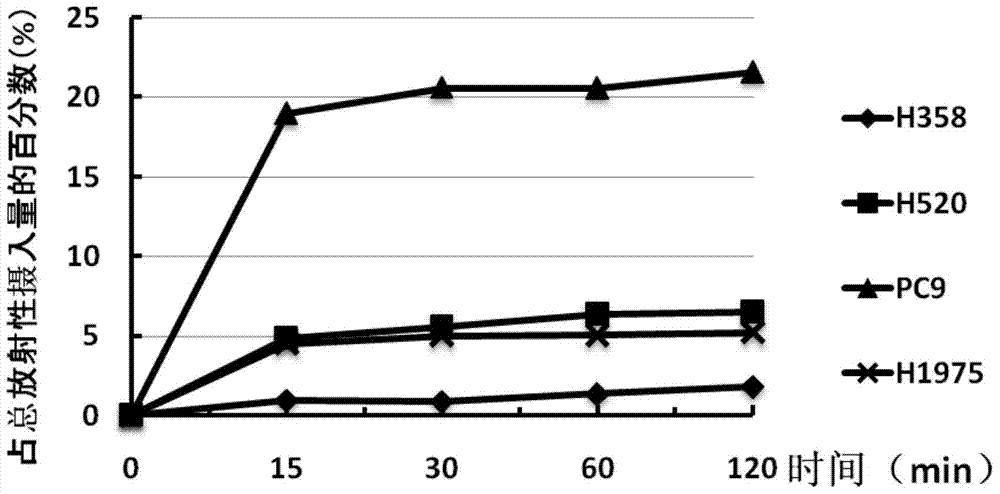

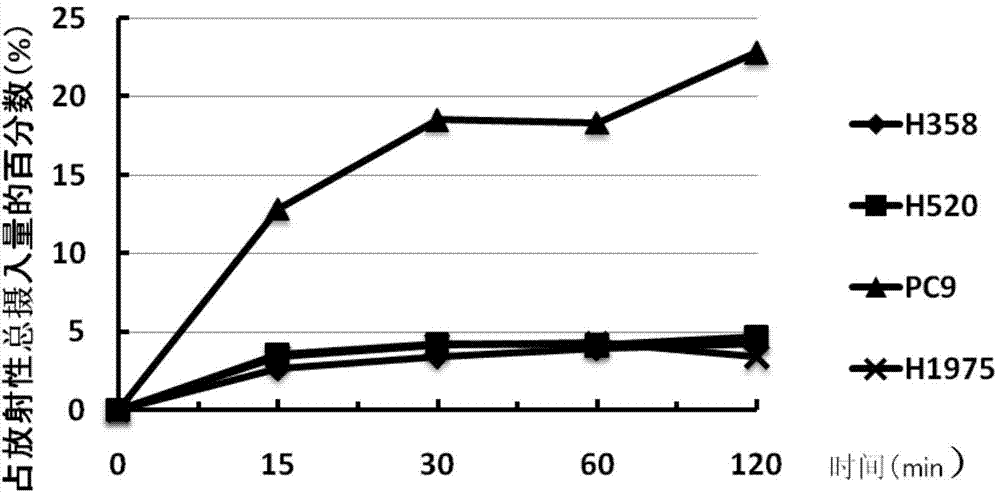

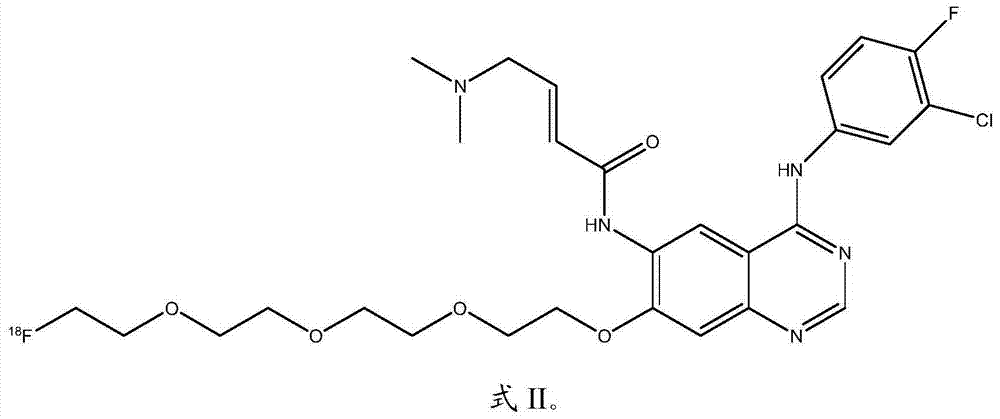

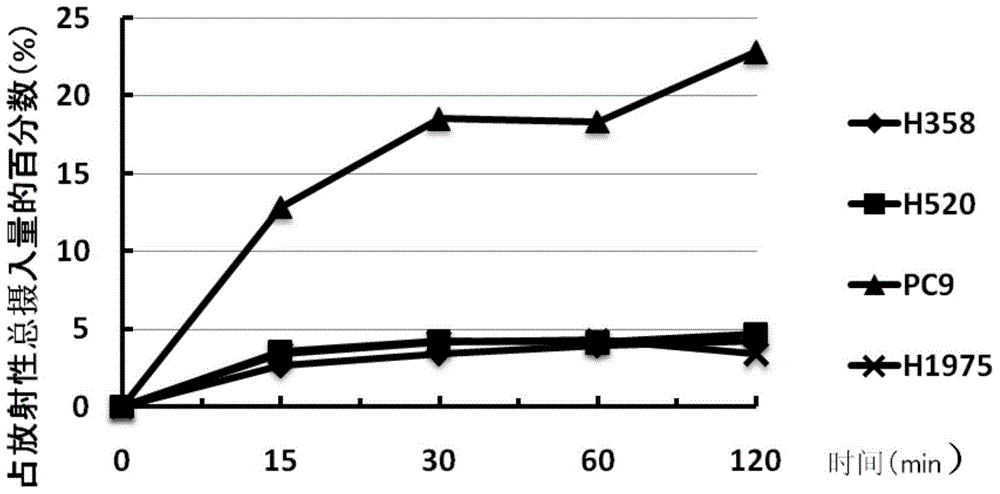

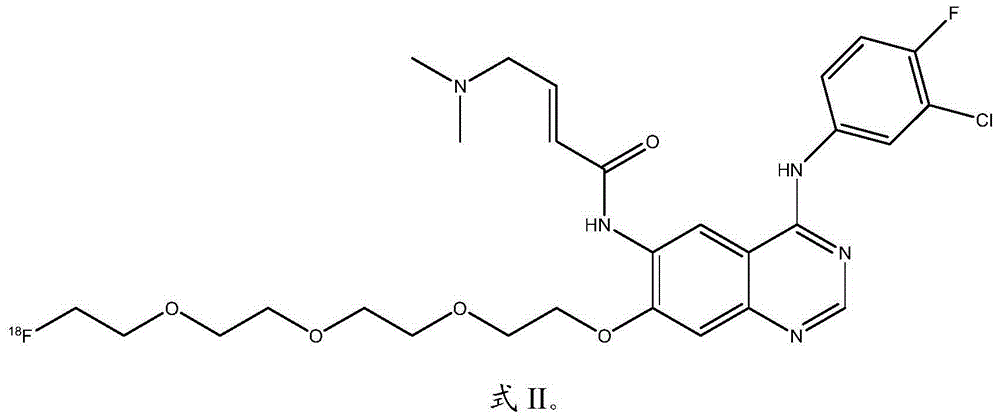

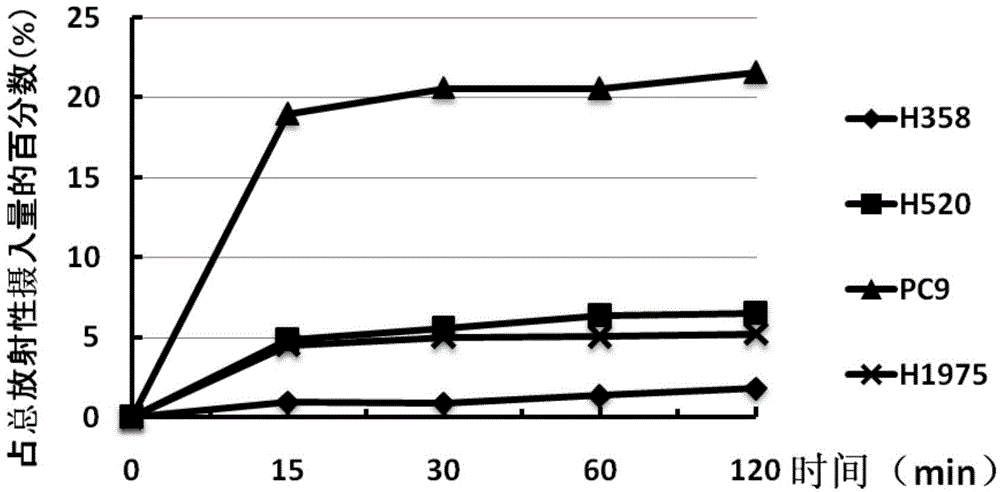

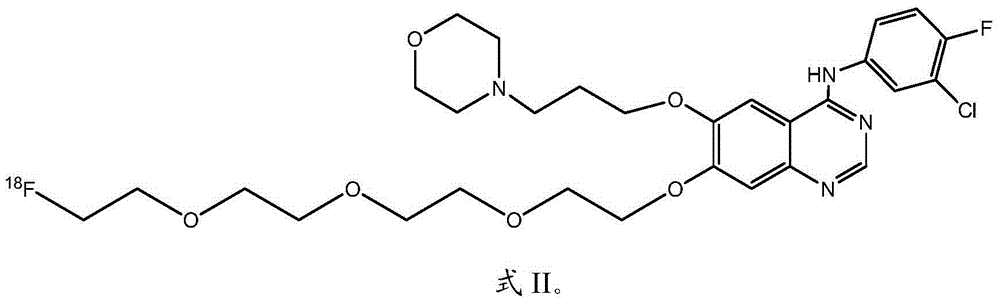

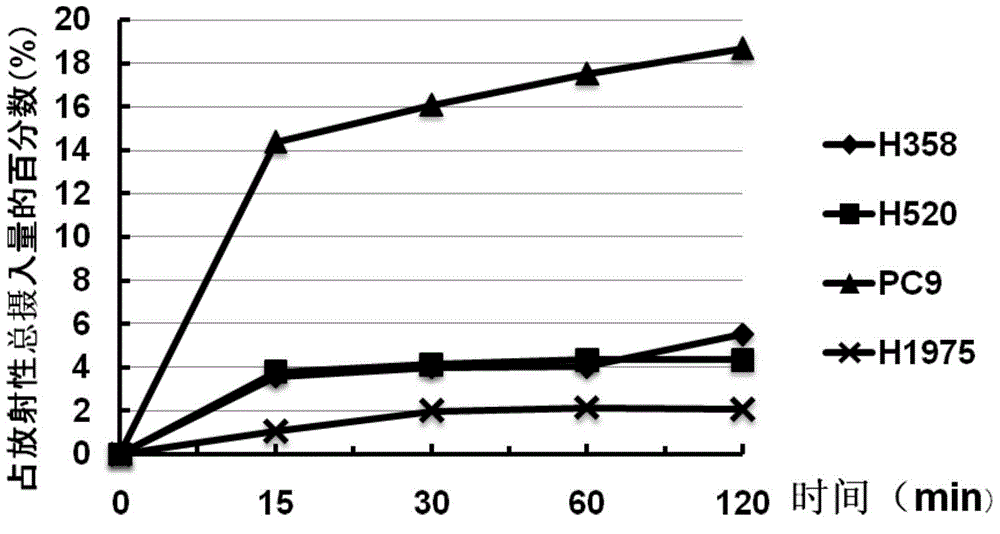

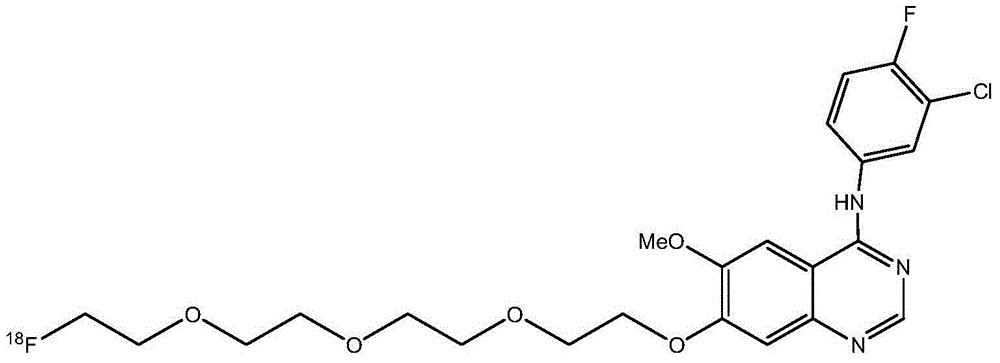

18F labeled quinazoline class EGFR (Epidermal Growth Factor Receptor) positron tracer agent and preparation method and application thereof

ActiveCN103656693AImprove hydrophilicityReduce uptake rateOrganic chemistryIn-vivo radioactive preparationsChemical synthesisChemical structure

The invention discloses an 18F labeled quinazoline class EGFR (Epidermal Growth Factor Receptor) positron tracer agent and a preparation method and application thereof and belongs to the field of chemical synthesis. The 18F labeled quinazoline class EGFR positron tracer agent has a chemical structure as shown in a formula II. The synthesized 18F labeled micro-molecular EGFR class positron tracer agent has the clinic values of diagnosis and therapeutic effect monitoring and particularly plays an important role in promoting personalized treatment. Besides, the invention further provides a one-step method, namely a method for fully-automatically synthesizing the 18F labeled quinazoline class EGFR positron tracer agent. The method has the characteristics of multiple purposes, high yield, high efficiency, short synthesis time, low cost and the like and can meet the requirements of large-scale production. The formula II is shown below.

Owner:HARBIN MEDICAL UNIVERSITY

18F-labeled quinazoline type EGFR (epidermal growth factor receptor) positron tracer, as well as preparation method and application thereof

ActiveCN103690972AImprove hydrophilicityReduce uptake rateOrganic chemistryMicrobiological testing/measurementChemical structureChemical synthesis

The invention discloses an 18F-labeled quinazoline type EGFR (epidermal growth factor receptor) positron tracer, as well as a preparation method and an application thereof and belongs to the field of chemical synthesis. The 18F-labeled quinazoline type EGFR positron tracer disclosed by the invention has a chemical structure as shown in a formula II. The synthesized 18F-labeled small molecular EGFR type positron tracer has clinical value of diagnosis and monitoring of treatment curative effect and particularly plays an important role in promoting personalized treatment. In addition, the invention further provides the method for full-automatic synthesis of the 18F-labeled quinazoline type EGFR positron tracer by one step, the method has the characteristics of multiple purposes, large yield, high efficiency, short synthesis time, low cost and the like, and the requirements of large-scale production can be further met.

Owner:HARBIN MEDICAL UNIVERSITY

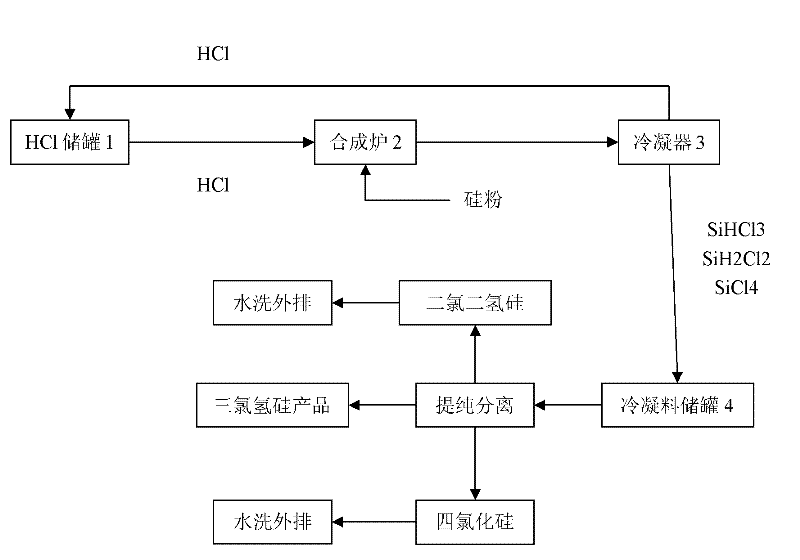

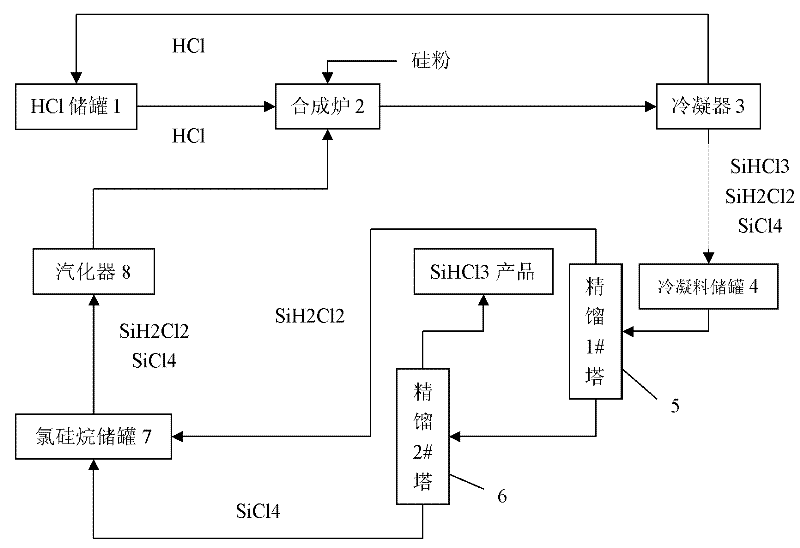

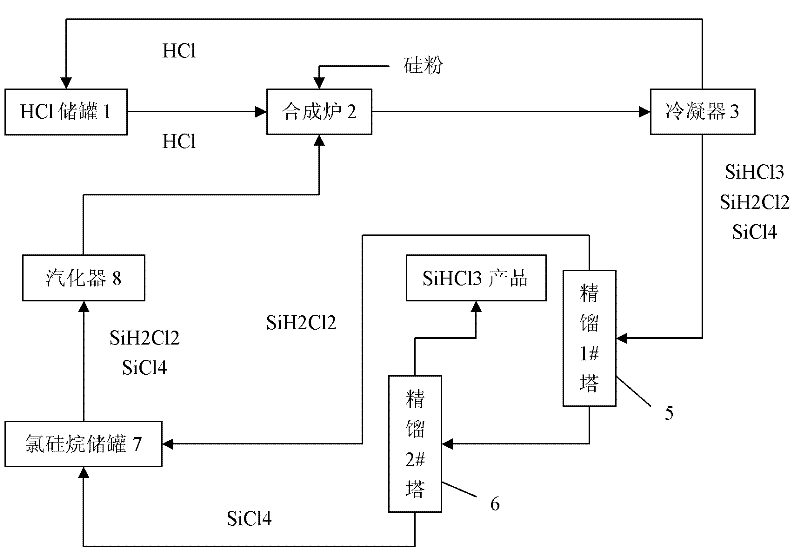

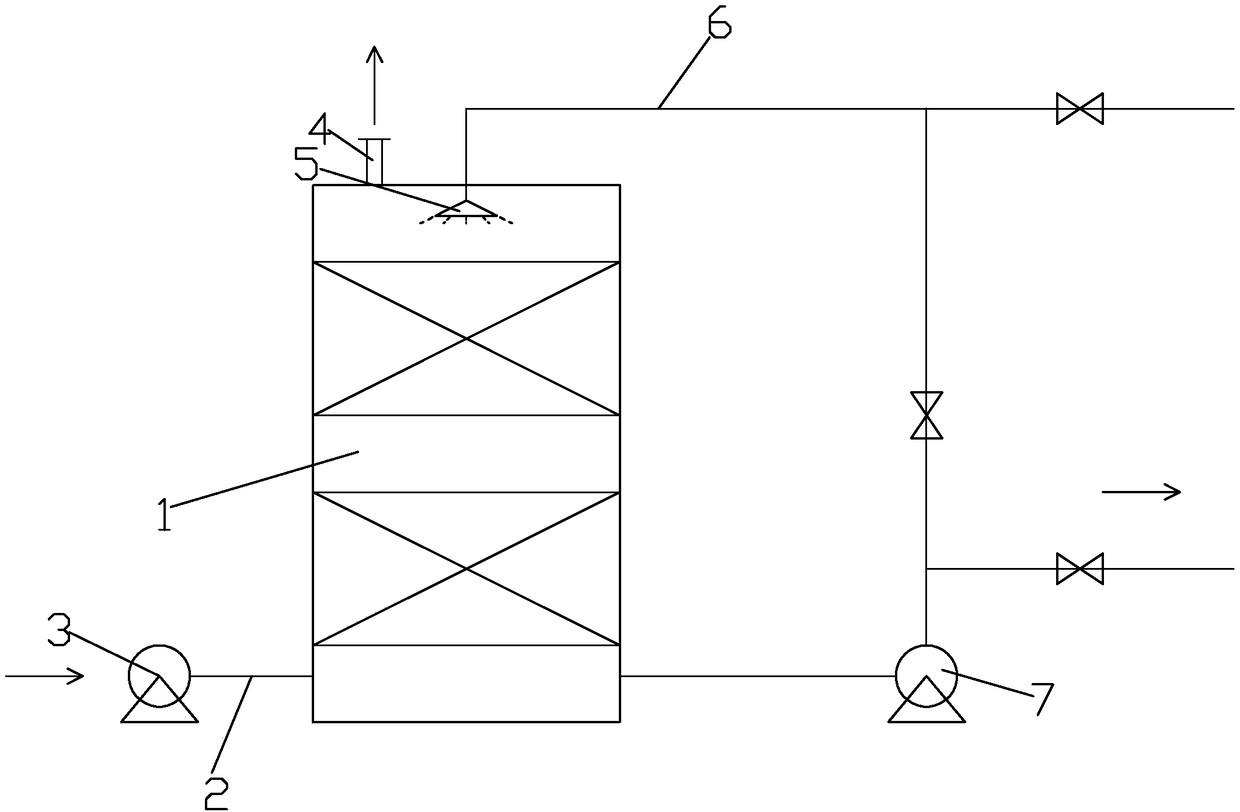

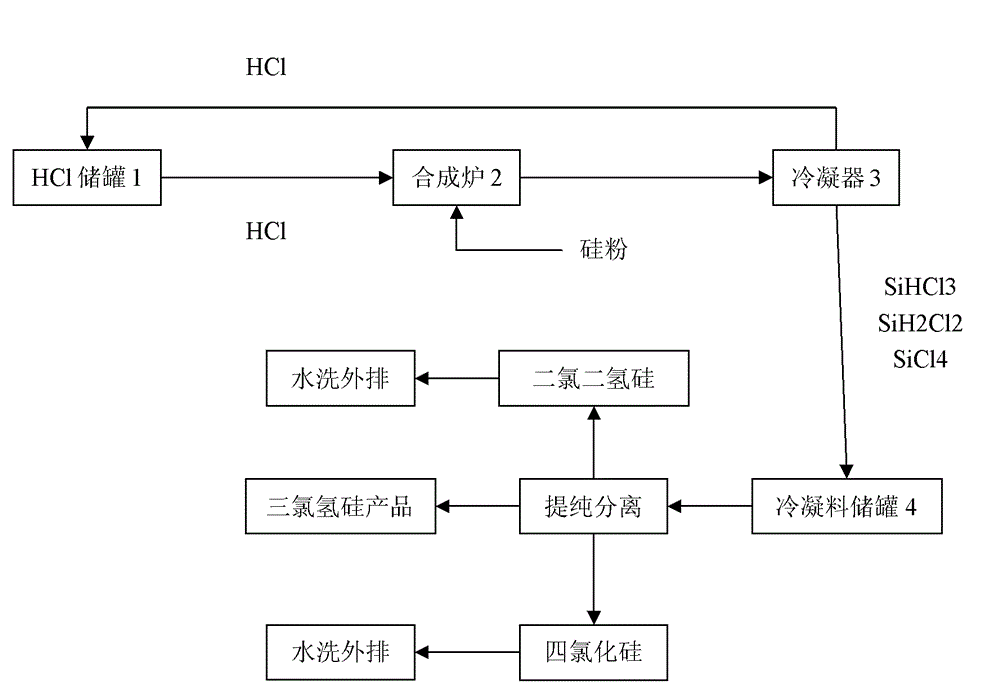

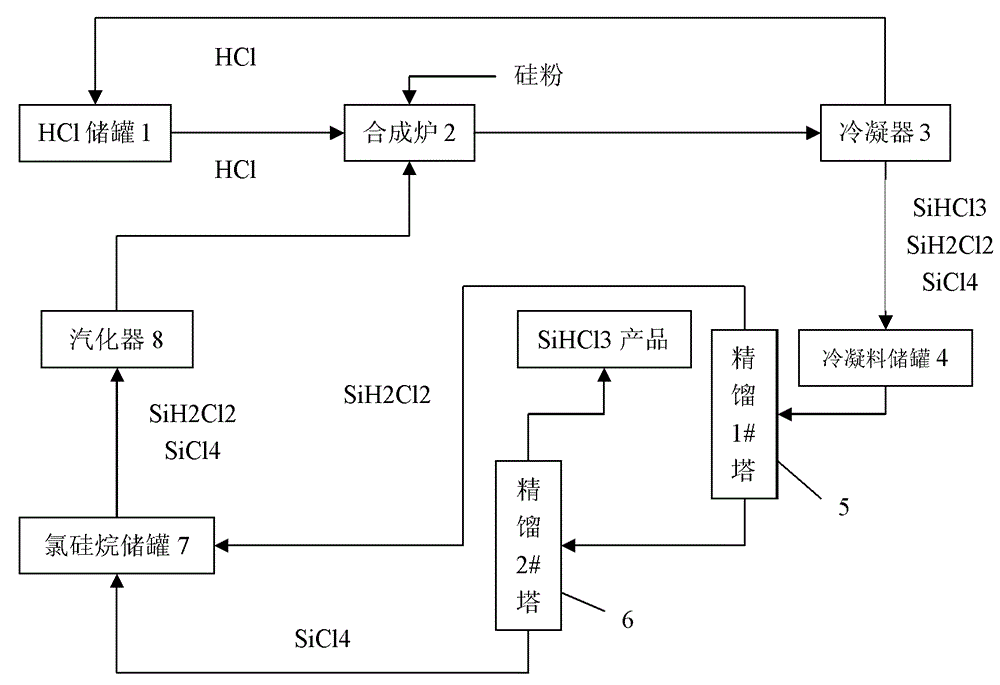

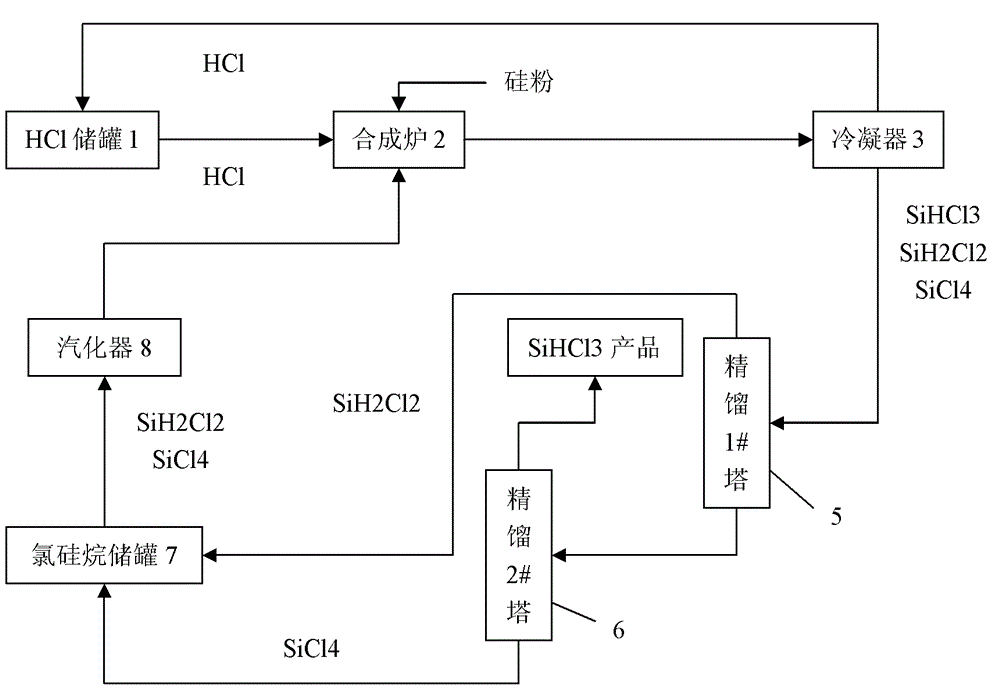

Trichlorosilane synthesis process and equipment

ActiveCN102390836ASynthesis Yield IncreasedReduce consumptionHalogenated silanesHydrogenSynthesis methods

The invention relates to a trichlorosilane synthesis process and equipment. The invention aims at disclosing an improved trichlorosilane synthesis method and equipment, which have the advantages of high yield and low cost and providing the method and equipment for continuously recycling byproducts, such as chlorosilane and silicon tetrachloride produced in the trichlorosilane synthesis process. The method comprises the following steps of: respectively separating chlorosilane and silicon tetrachloride from synthetic product materials by using a rectified separation method, gasifying the chlorosilane and the silicon tetrachloride and then introducing into a synthesis reactor, and enabling the chlorosilane content and the silicon tetrachloride content to reach a dynamic balance in the operation process. Therefore, according to the invention, the synthesis output of the trichlorosilane is improved, consumption of raw materials, hydrogen, chlorine gas and the like is reduced, and thus the production cost is reduced.

Owner:巴彦淖尔聚光硅业有限公司

Method for synthesizing glutathione through fermentation

InactiveCN103695506AIncrease productionIncrease inhibitory concentrationMicroorganism based processesFermentationBiotechnologyMicrobiology

The invention provides a method for synthesizing glutathione through fermentation, belonging to the field of production of glutathione. According to the method for synthesizing glutathione through fermentation, parameters such as concentration of a seed bacteria liquid, inoculum size and pH of a fermentation medium are optimized, the growth activity and fermentation activity of the yeast are maintained, the output of the glutathione is improved; and in fermentation, cysteine is added into the fermentation medium, the adding time and adding volume are optimized, so that the inhibition concentration of the glutathione can be improved, and the yield of the synthesized glutathione is further improved.

Owner:CHENGDU YATU BIOLOGICAL TECH

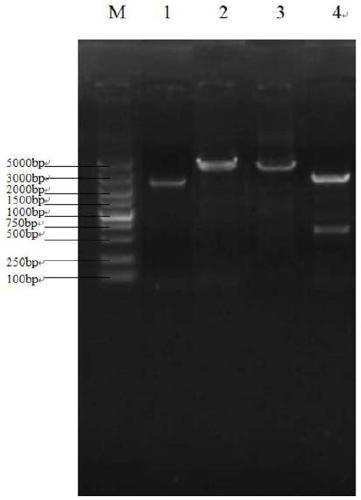

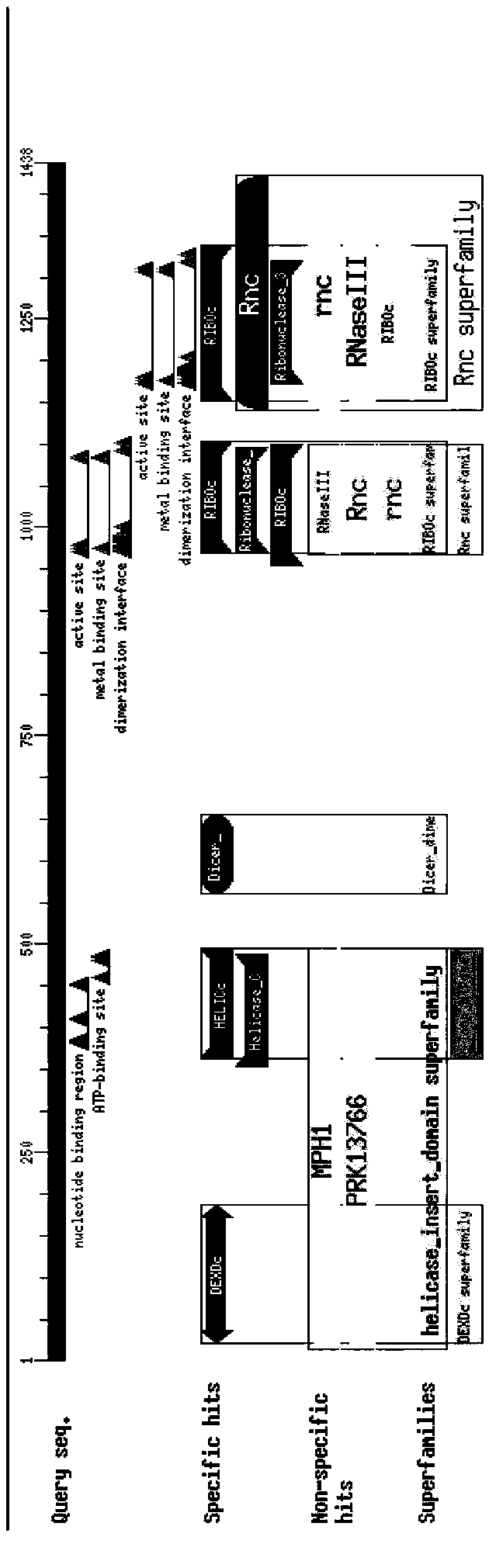

Grifola frondosa glucan synthase, and encoding gene and application thereof

InactiveCN109609525AEffective Resolution StrategiesEfficient methodFungiMicroorganism based processesMolecular levelGene silencing

The invention belongs to the technical fields of genetic breeding and genetic engineering of edible fungi, and specifically relates to grifola frondosa glucan synthase as well as an encoding gene andapplication thereof. The encoding gene of glucan synthesis key enzyme-glucan synthase is obtained for the first time from clones of grifola frondosa mycelium genome by the invention; key roles of thegene in grifola frondosa mycelium growth and glucan synthesis are demonstrated by gene silencing; and the glucan synthase is over-expressed in grifola frondosa by adopting an genetic engineering technology so as to have thallus growth of recombinant strains and synthesis yield of glucan significantly increased. The grifola frondosa glucan synthase as well as the encoding gene and the application thereof are helpful for understanding synthesis mechanism of edible and medicinal fungal polysaccharides at molecular level, developing metabolic engineering study on edible and medicinal fungal polysaccharide synthesis, and providing important technical support and reference for producing glucan with stable quality by performing high-efficiency fermentation.

Owner:JIANGSU UNIV

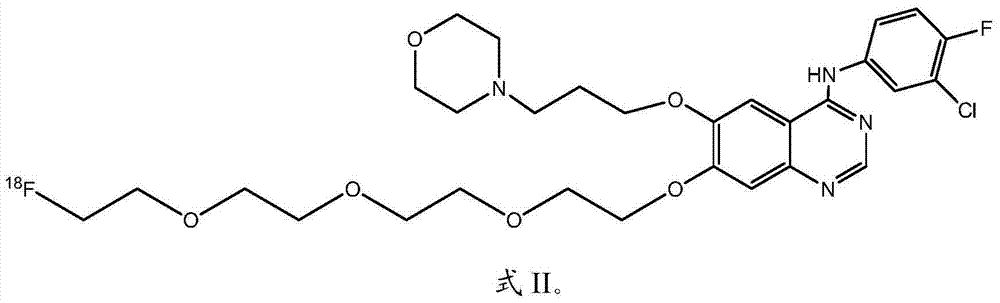

18F-labelled quinazolines irreversible EGFR (epidermal growth factor receptor) positive electron tracer agent, as well as preparation method and application thereof

ActiveCN103656694AShorten the synthesis processHigh yieldOrganic chemistryMicrobiological testing/measurementChemical structureChemical synthesis

The invention discloses an 18F-labelled quinazolines irreversible EGFR (epidermal growth factor receptor) positive electron tracer agent, as well as a preparation method and application thereof. The 18F-labelled quinazolines irreversible EGFR positive electron tracer agent has a chemical structure represented by the formula II. The synthesized 18F-labelled small-molecular irreversible EGFR positive electron tracer agent has a clinical value for diagnosing and monitoring a treating effect and particularly plays an important role in pushing individual-based treatment. Furthermore, the invention further provides a one-step method for synthesizing the 18F-labelled small-molecular irreversible EGFR positive electron tracer agent. The method has the characteristics of multiple purposes, high yield, high efficiency, short synthesis time, low cost and the like and can meet a requirement on large-scale production.

Owner:HARBIN MEDICAL UNIVERSITY

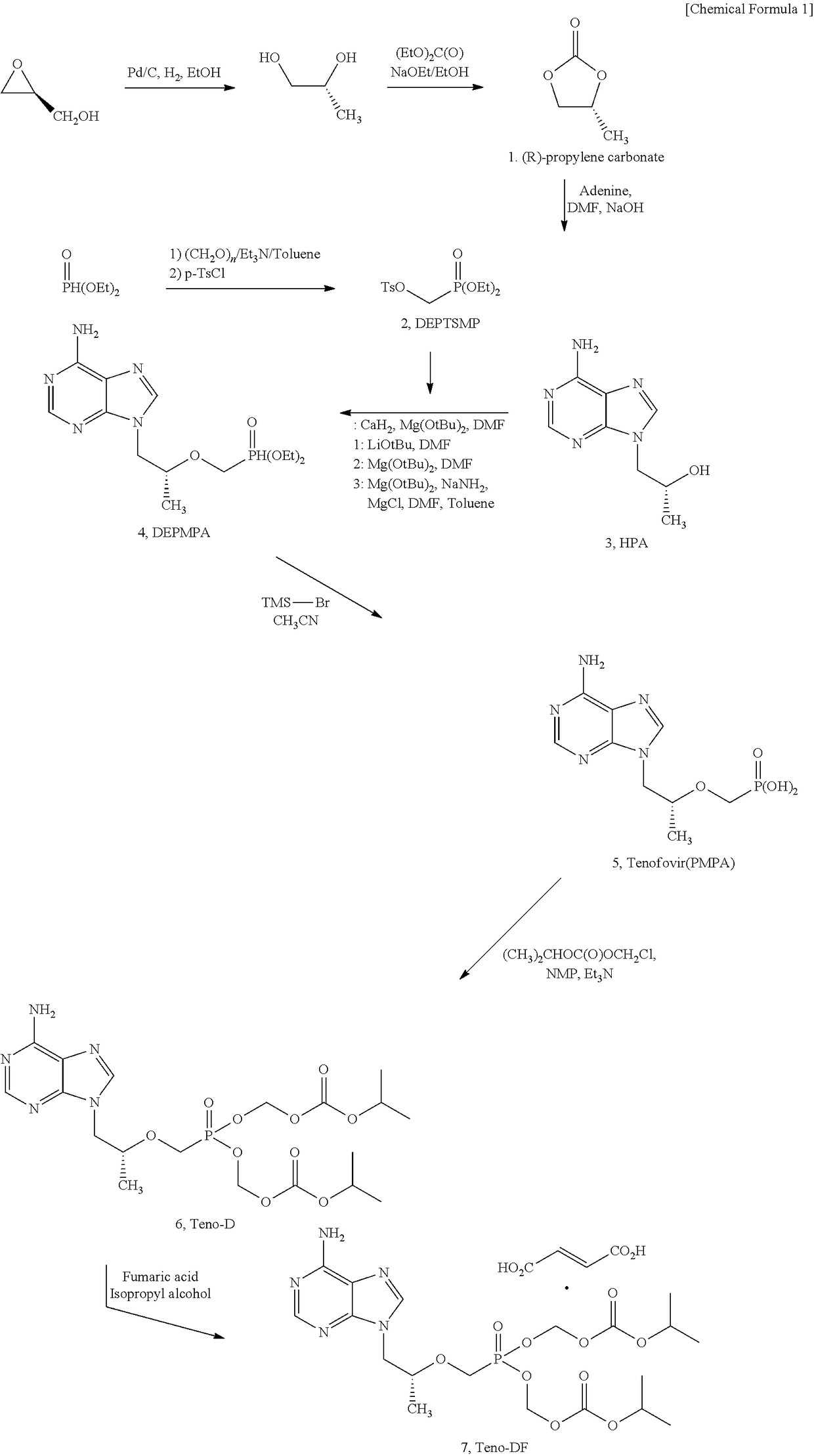

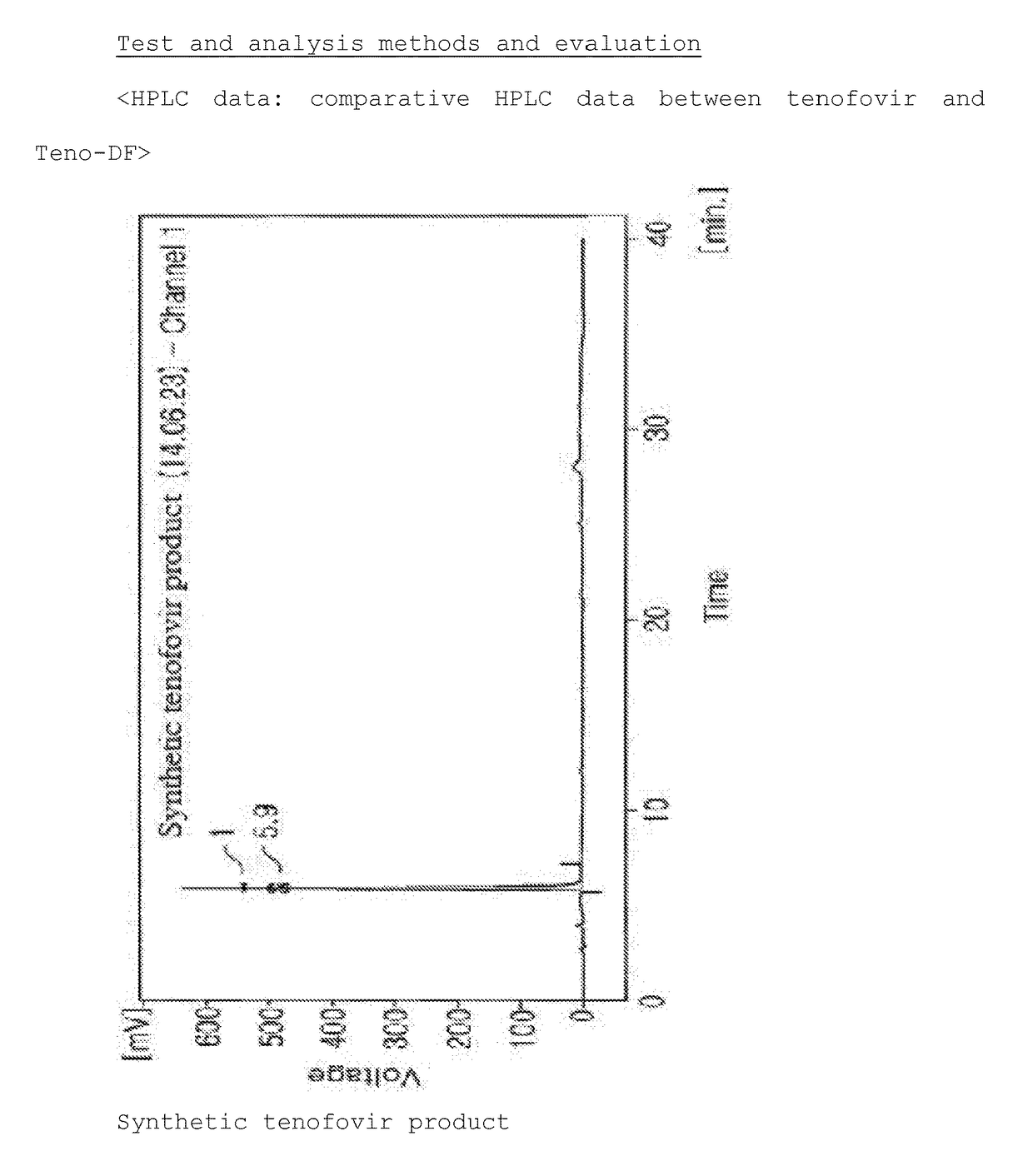

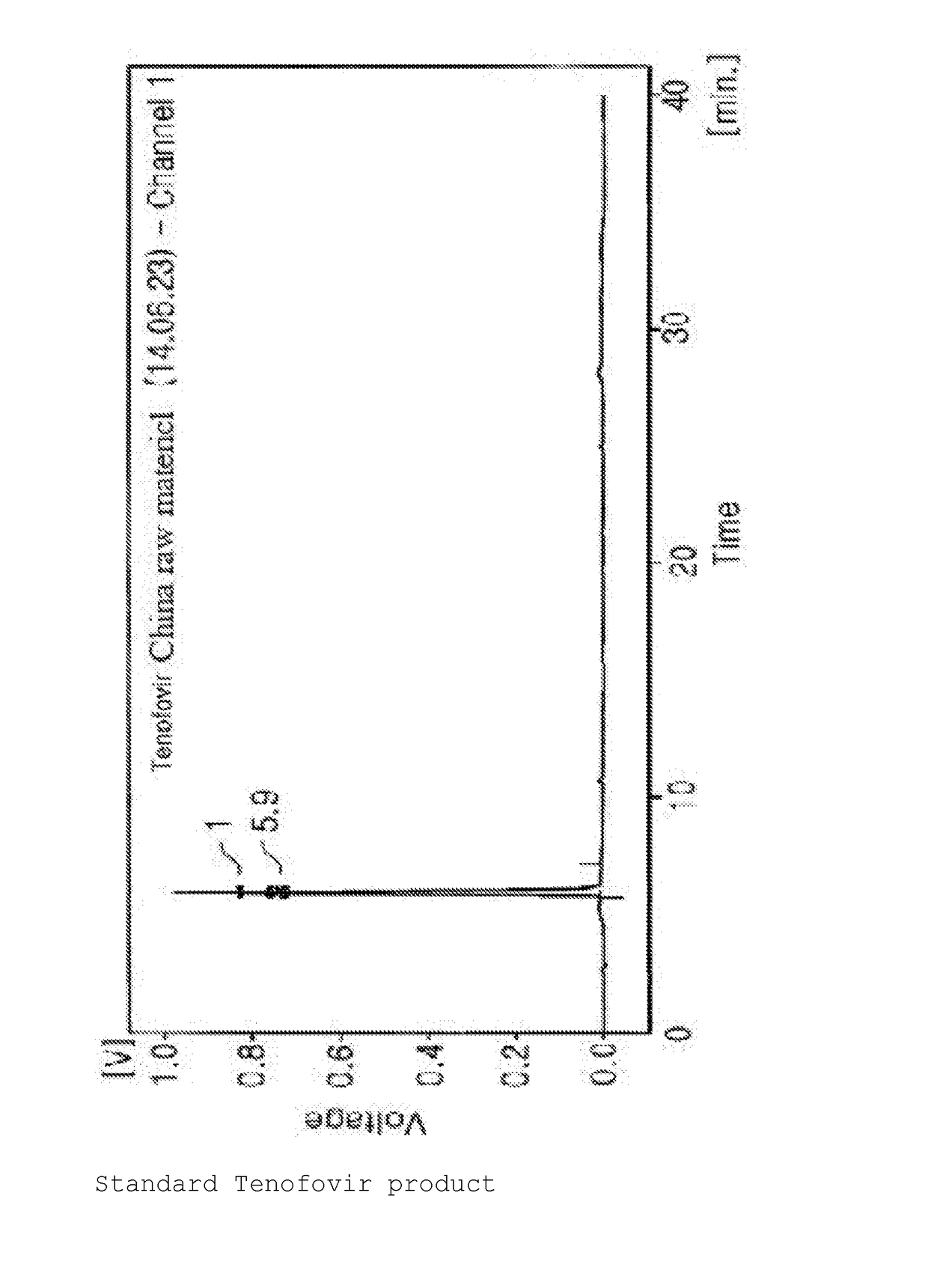

Synthesis Method For Improved Tenofovir Disoproxil Fumarate Using Ion-Exchange Resin And Method For Preparing Oral Dissolving Film Form Using The Same

InactiveUS20170354668A1Keep dryHigh purityAntiviralsPharmaceutical non-active ingredientsAdditive ingredientSynthesis methods

The present invention relates to a synthesis method of preventing the formation of impurities and byproducts in the synthesis of tenofovir disoproxil fumarate (Teno-DF) used as a medicine for hepatitis B and HIV treatment due to its function to promote bioactivities. In the synthesis method of the present invention, an ion-exchange resin (Dowex 50W hydrogen form, sulfonic acidic cation exchange resin) is used to enhance the yield and purity of the compound. The present invention also relates to a method of preparing an oral dissolving film dosage form in the manufacture of a medicine using the tenofovir compound with high purity obtained by the synthesis method of the present invention as an effective ingredient.

Owner:PERSON CO LTD

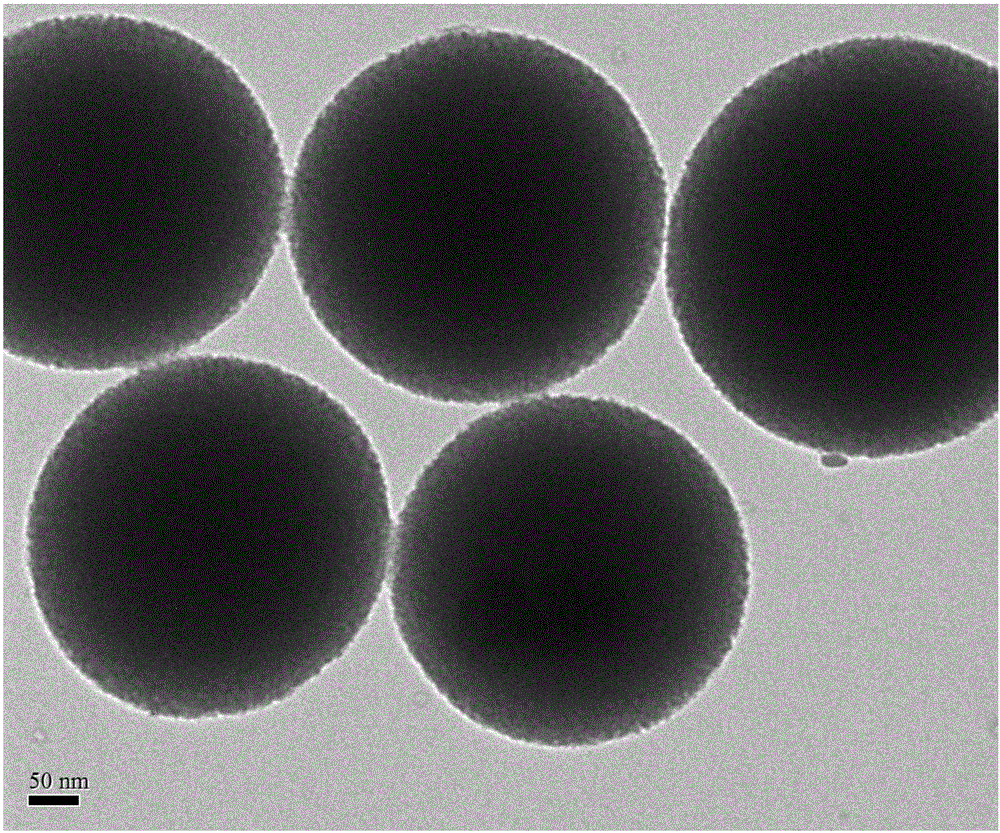

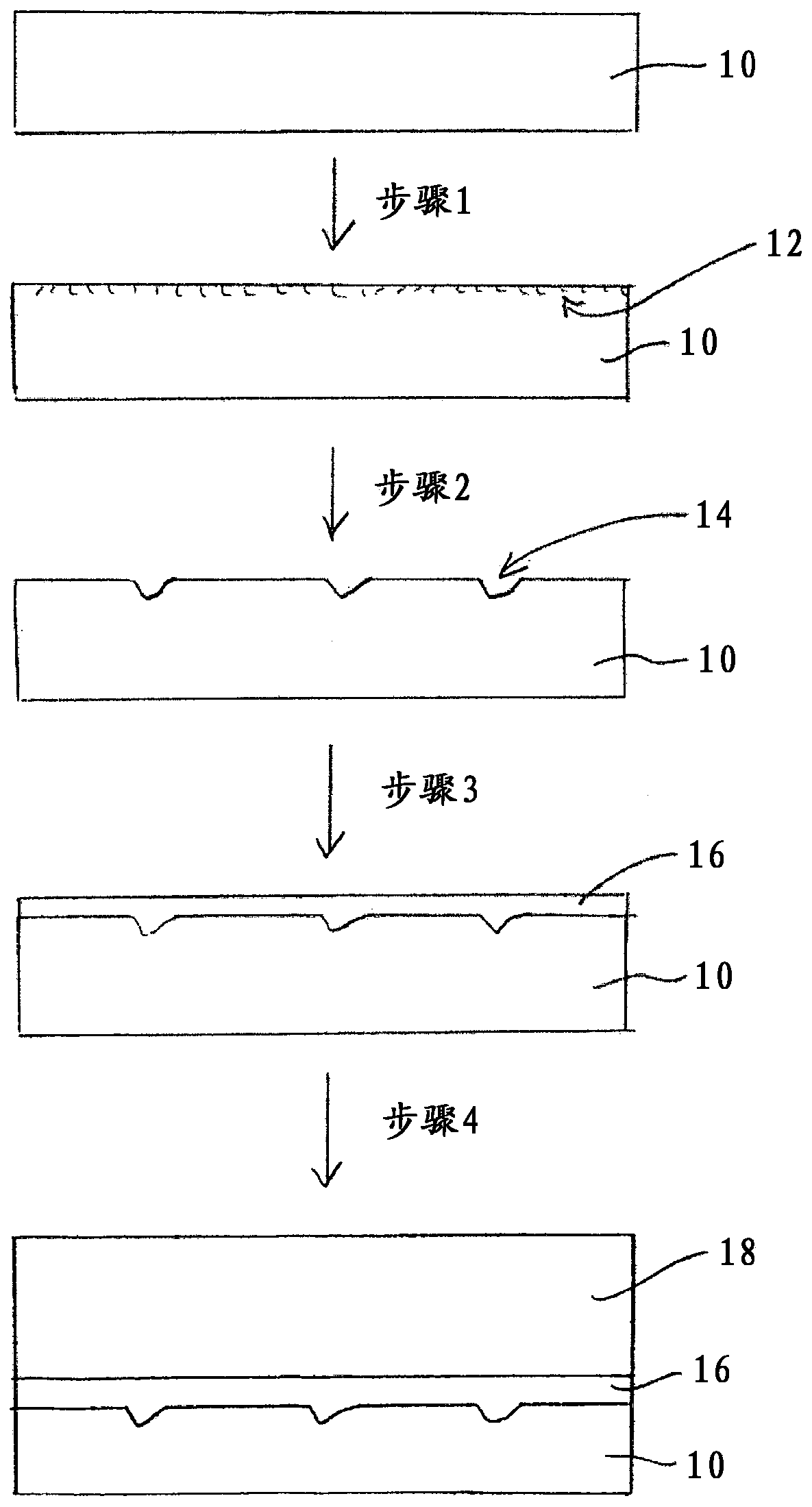

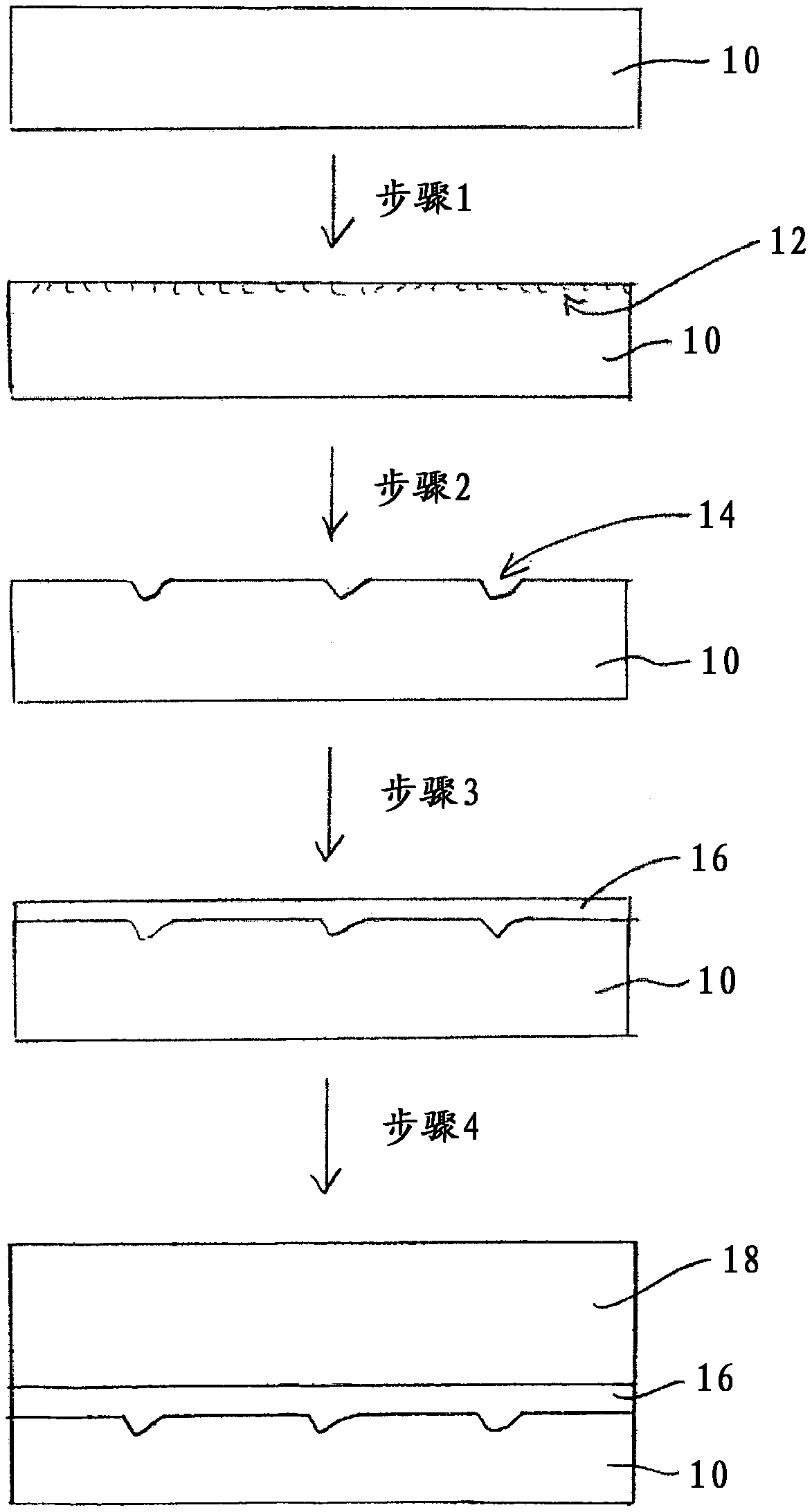

High-yield mesoporous silica nano-particle and folic acid targeting modification method thereof

InactiveCN105905912AThe synthesis process is simpleImprove efficiencyPowder deliverySilicaNanometreFolic acid

The invention relates to a high-yield mesoporous silica nano-particle and a folic acid targeting modification method thereof. A preparation method for the high-yield mesoporous silica nano-particle comprises the following steps: 1) synthesis of a silica nano-particle: preparing the silica nano-particle with a diameter of 300 to 500 nm from ethyl orthosilicate by using a sol-gel method; and 2) preparation of a mesoporous silica nanometer carrier: removing a template of cetyl trimethyl ammonium bromide (CTAB) by using sodium chloride so as to prepare the mesoporous silica nanometer carrier with a pore size of 0.5 to 2 nm. Meanwhile, folic acid targeting modification of the mesoporous silica nano-particle is carried out. The invention has the beneficial effects that synthesis process is simple, nontoxic and fast; the prepared mesoporous silica nano-particle has pore size of 0.5 to 2 nm and synthesis output is as high as 500 to 1000 mg, substantially increased compared with the normal output of 10 to 100 mg in the prior art; and after folic acid targeting modification of the mesoporous silica nano-particle, the carrier has improved efficiency in entering tumor cells.

Owner:TIANJIN UNIV

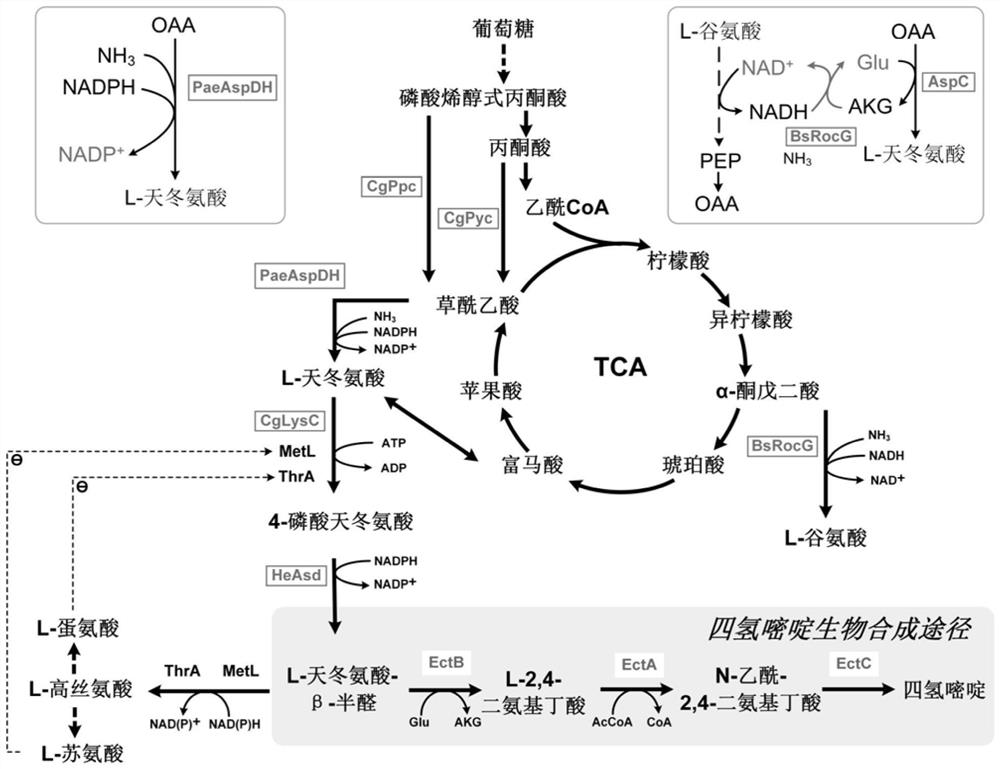

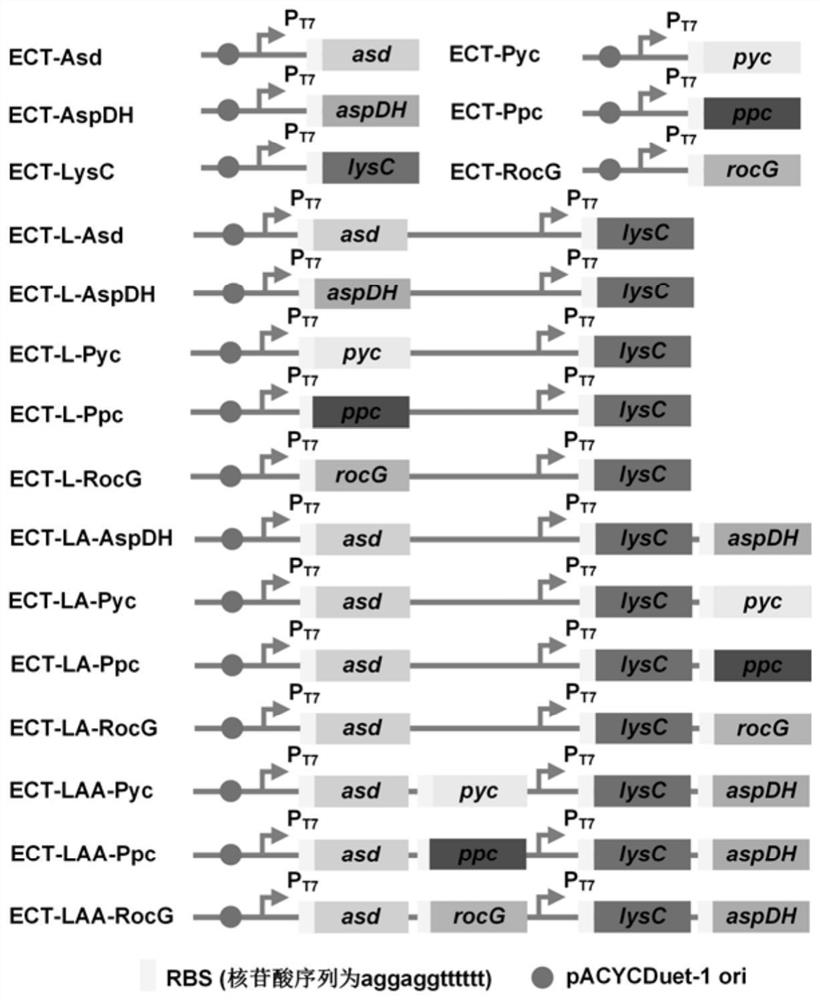

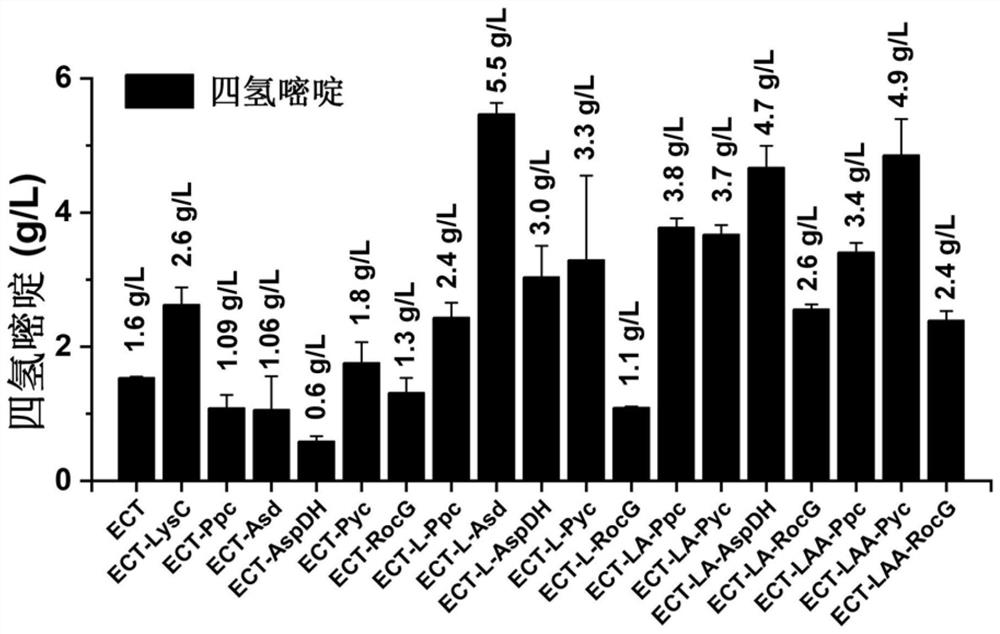

Method for constructing and optimizing ectoine producing engineering strain

PendingCN113186143AEasy to prepareSynthesis Yield IncreasedBacteriaTransferasesBiotechnologyRecombinant escherichia coli

The invention discloses a method for constructing and optimizing an engineering strain for producing ectoine, and belongs to the technical field of biological engineering. The invention provides an Escherichia coli engineering bacterium ECT-LA capable of producing ectoine under a low-salt condition. The bacterium is based on escherichia coli E.coli BL21 (DE3) and comprises an ectoine synthetic gene cluster ectABC controlled by a T7 promoter and exogenous genes lysCC932T and asd; a preparation method of ectoine is optimized futher. The recombinant escherichia coli constructed by the invention takes glucose as a substrate, and the yield of ectoine can reach 60g / L after fed-batch fermentation is performed for 56h.

Owner:JIANGNAN UNIV

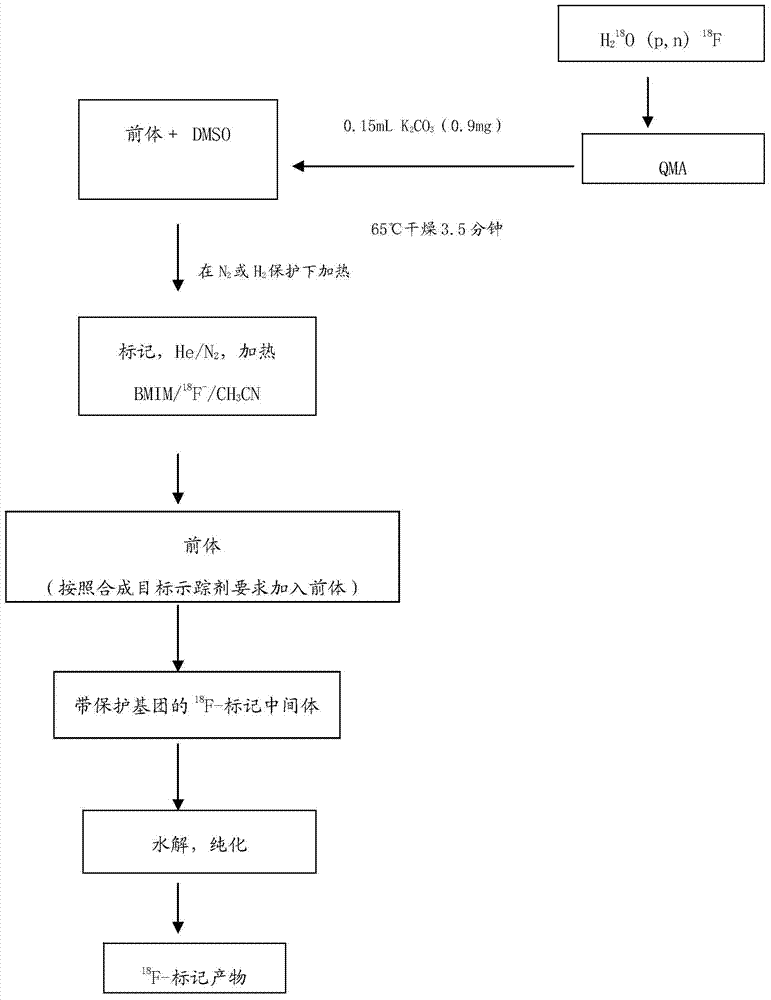

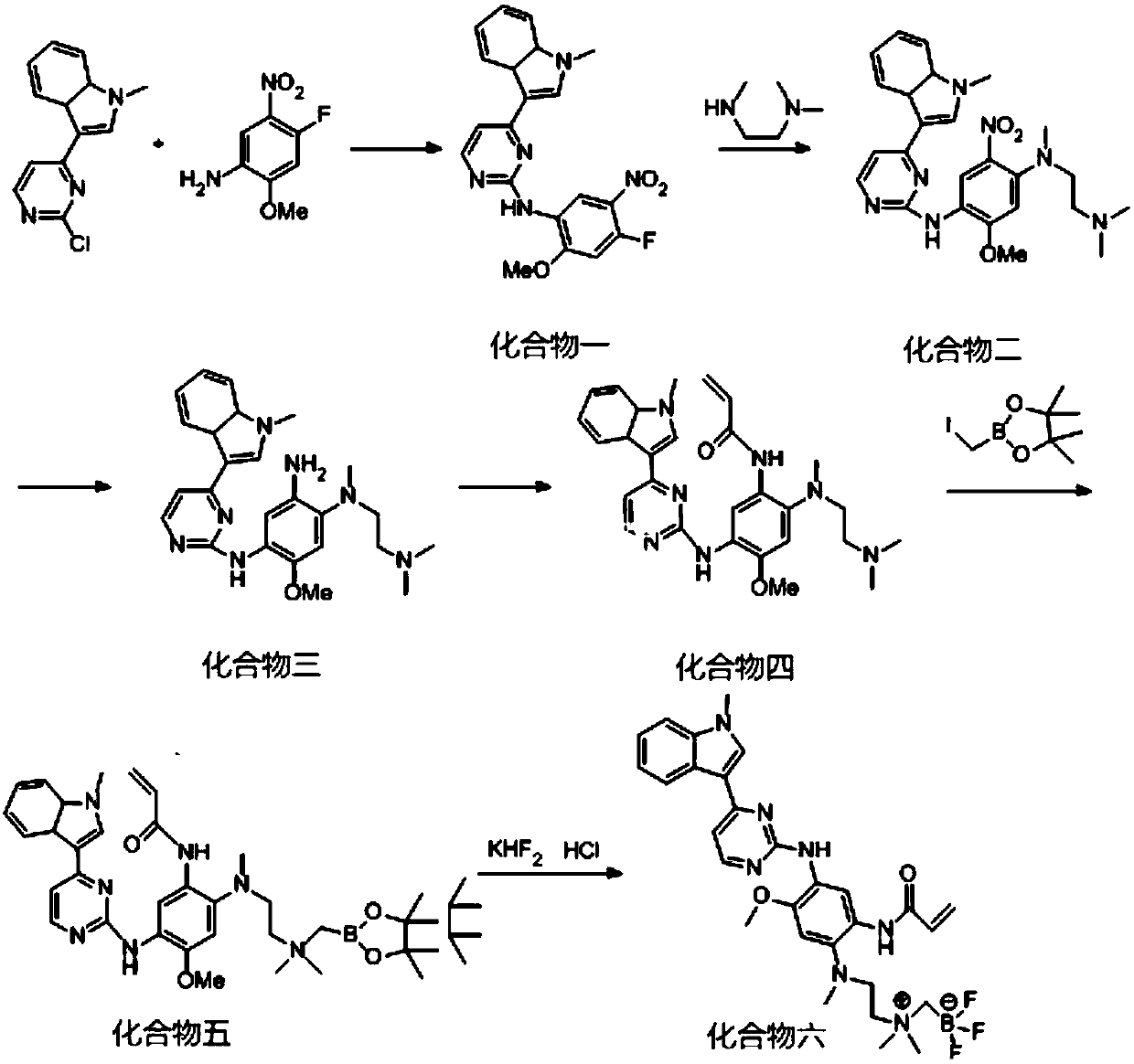

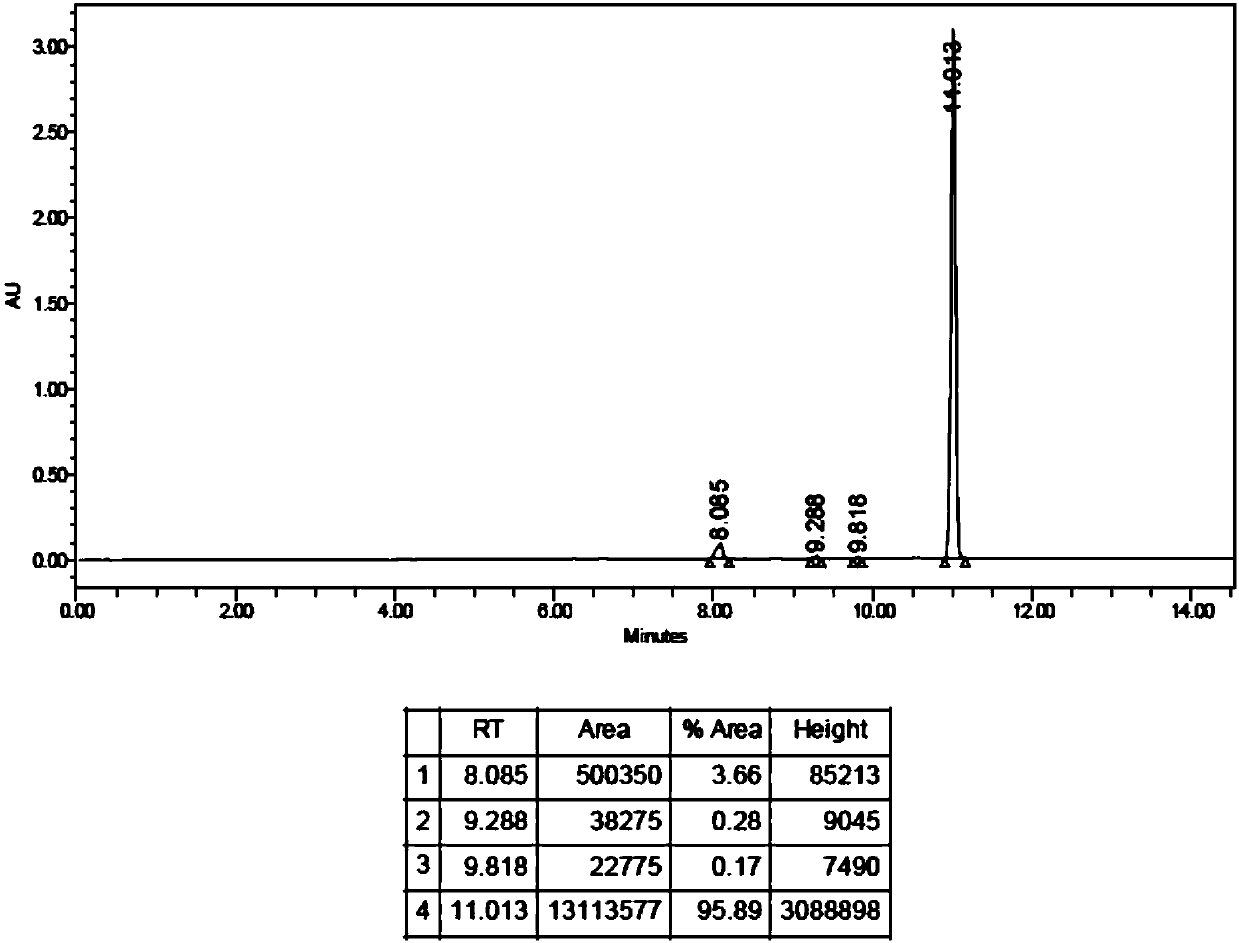

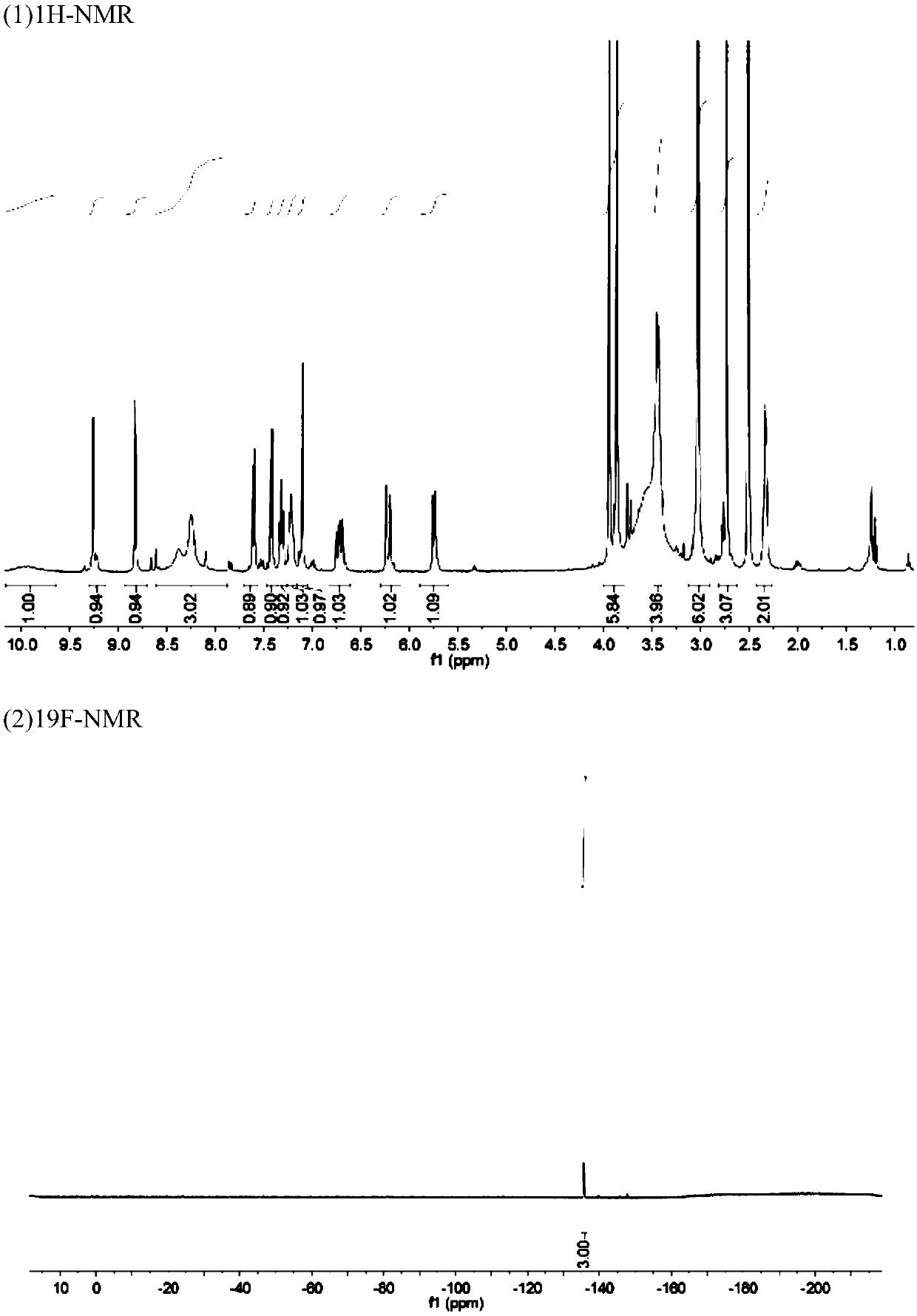

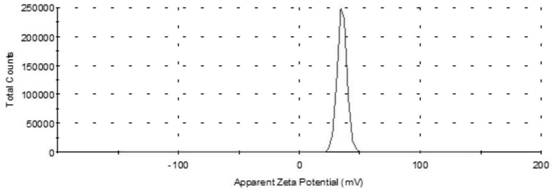

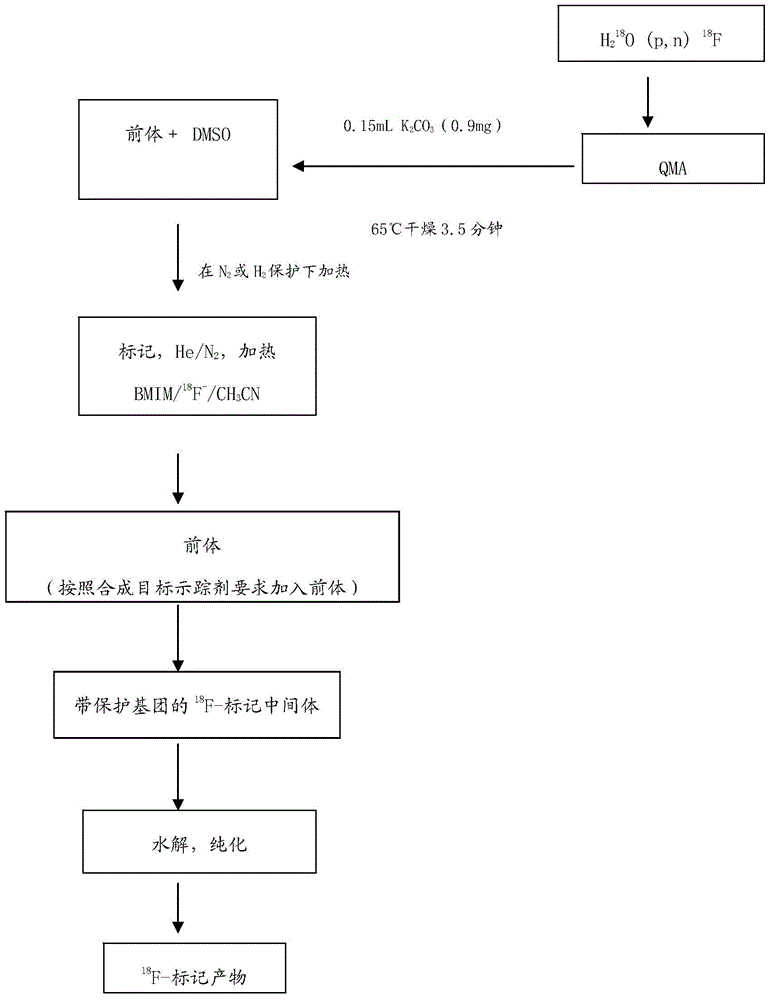

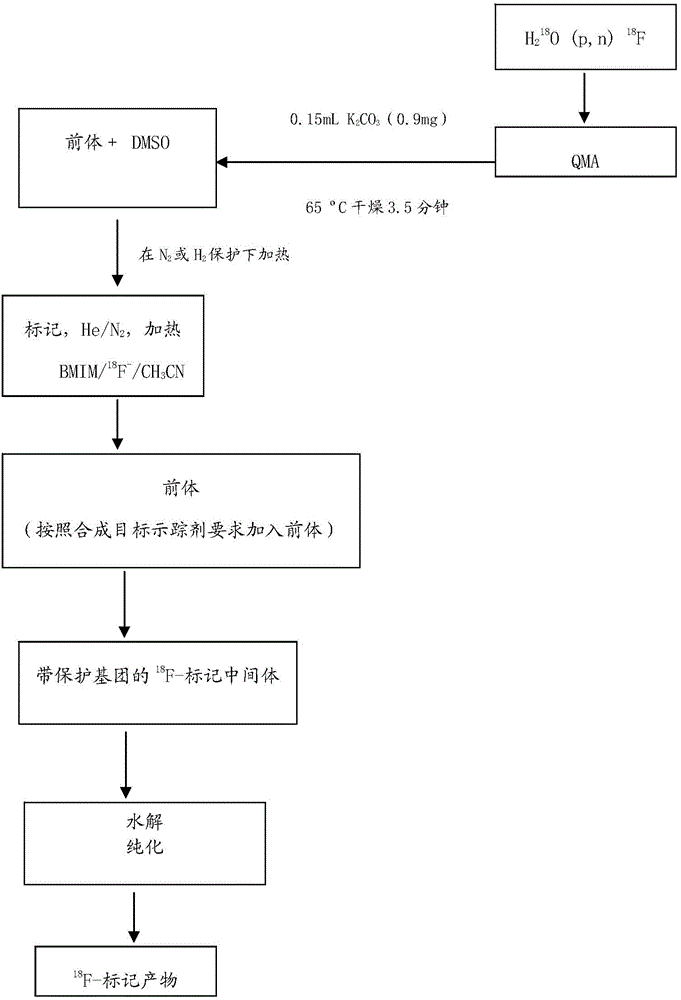

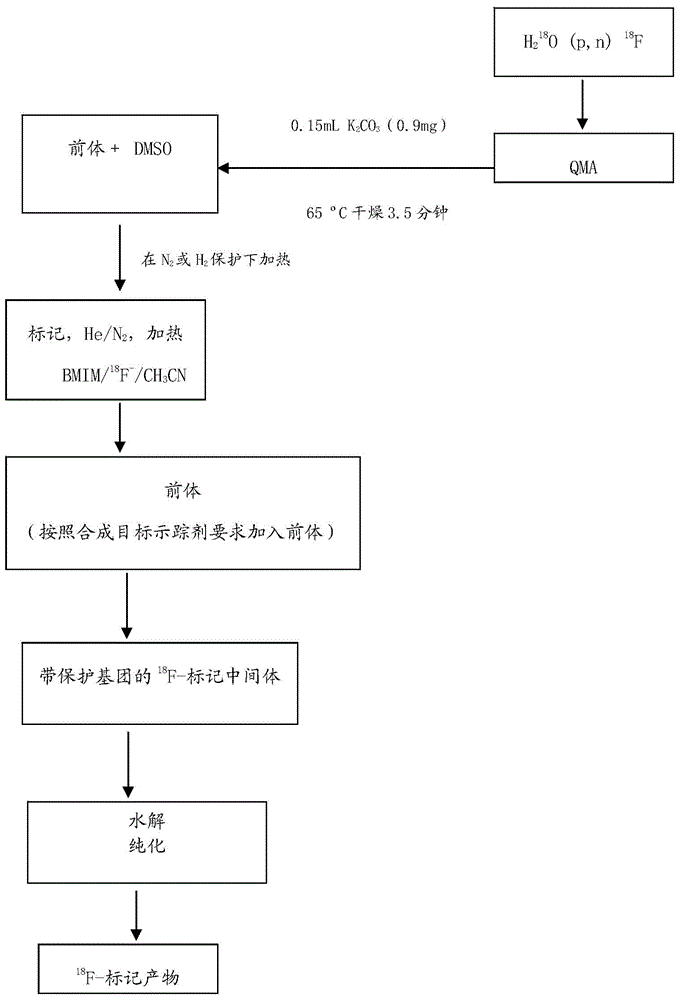

Method for full-automatically synthesizing <18>F-marked pyrimidine acrylamide based EGFR positive-electron tracer agent through one-step method

InactiveCN107596394ATroubleshootHigh yieldOrganic chemistryRadioactive preparation carriersChemical synthesisSolid phase extraction

The invention discloses a method for full-automatically synthesizing a <18>F-marked pyrimidine acrylamide based EGFR positive-electron tracer agent through a one-step method, and belongs to the fieldof chemical synthesis. The method sequentially comprises the following steps that (1) <18>F ions from an accelerator and water are conveyed to a receiving bottle and guided into an anion exchange column; (2) <18>F ions in the anion exchange column are eluted with a mixed solution formed by strong alkali and weak acid salt, acetonitrile and ionic liquid, and then are conveyed to a reaction bottle;(3) precursor is dissolved in a DMSO or acetonitrile or DMF solution, a buffer solution is added into the former solution to enable pH of the former solution to be 2, and the obtained solution is added into the reaction bottle and heated under protection of inert gas; (4) the temperature is lowered, and coarse products in the reaction bottle are purified through a solid-phase extraction C18 pillaret; and (5) target products of a solution obtained in the step (4) are separated and collected, so that the positive-electron tracer agent is obtained. The method has the characteristics of multi-purpose, large yield, high efficiency, short synthesis time, low cost and the like, and can meet the requirement for large-scale production.

Owner:HARBIN MEDICAL UNIVERSITY

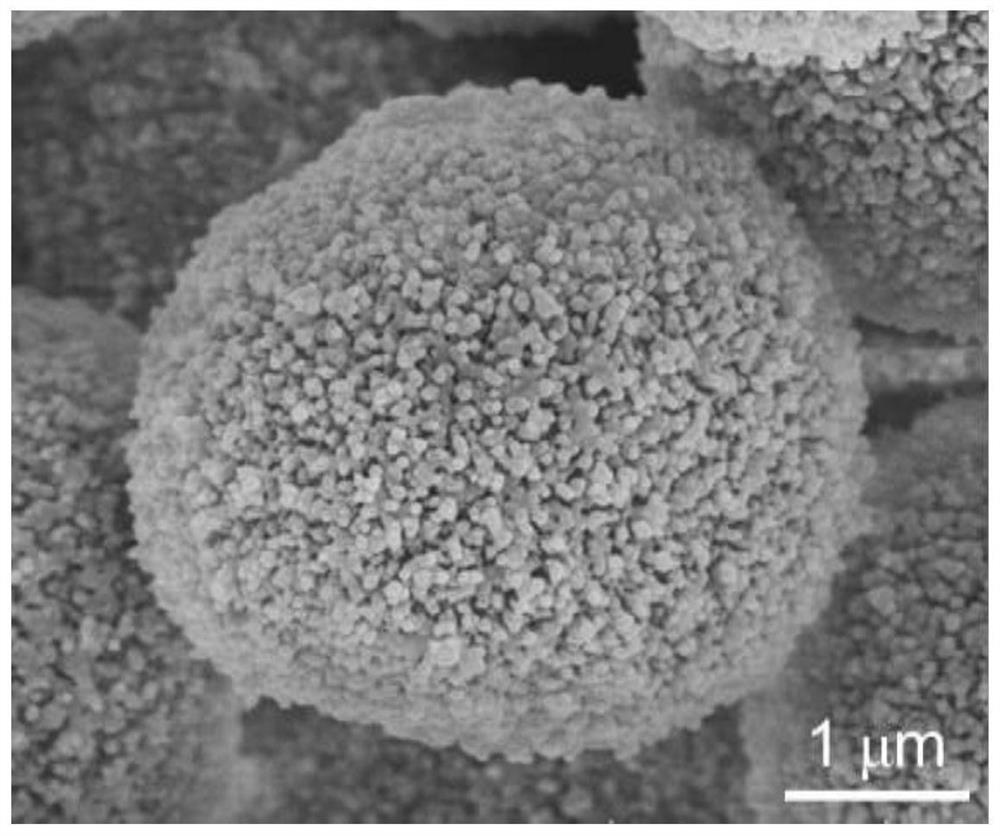

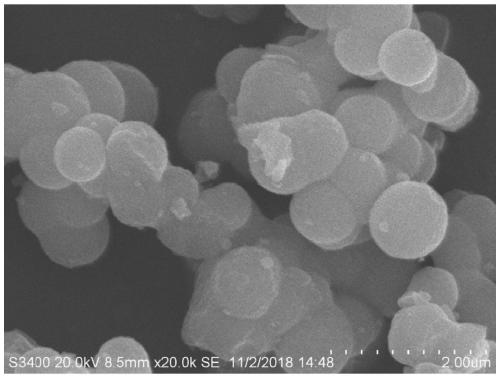

Ion exchange polymer microsphere and synthesis method thereof

PendingCN114805657AThe reaction process is simpleExperimental conditions are simpleMicroballoon preparationMicrocapsule preparationIon exchangeHydrophilic polymers

The invention relates to an ion exchange polymer microsphere and a synthesis method thereof. The microsphere has a micron size, is internally composed of a hydrophobic polymer, and has a solid and compact structure; and the outer part is composed of a charged hydrophilic polymer and has a nano-porous structure. By changing the types of the hydrophobic polymer and the charged hydrophilic polymer, the chemical components and the surface appearance of the microspheres can be regulated and controlled. The microspheres have uniform size and morphology, the preparation method is simple, large-scale production is easy, and the microspheres have wide industrial application value. The ion exchange polymer microsphere with the micro-nano hierarchical heterostructure has great value in adsorption and separation of various molecules, ions and particles, and is expected to be applied to the fields of medicine purification, food detection, environmental governance and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Single crystal synthetic diamond material via chemical vapour deposition

PendingCN110023545AHigh nitrogen contentIncrease strainPolycrystalline material growthAfter-treatment detailsRefractive indexSingle crystal

Owner:ELEMENT SIX TECH LTD

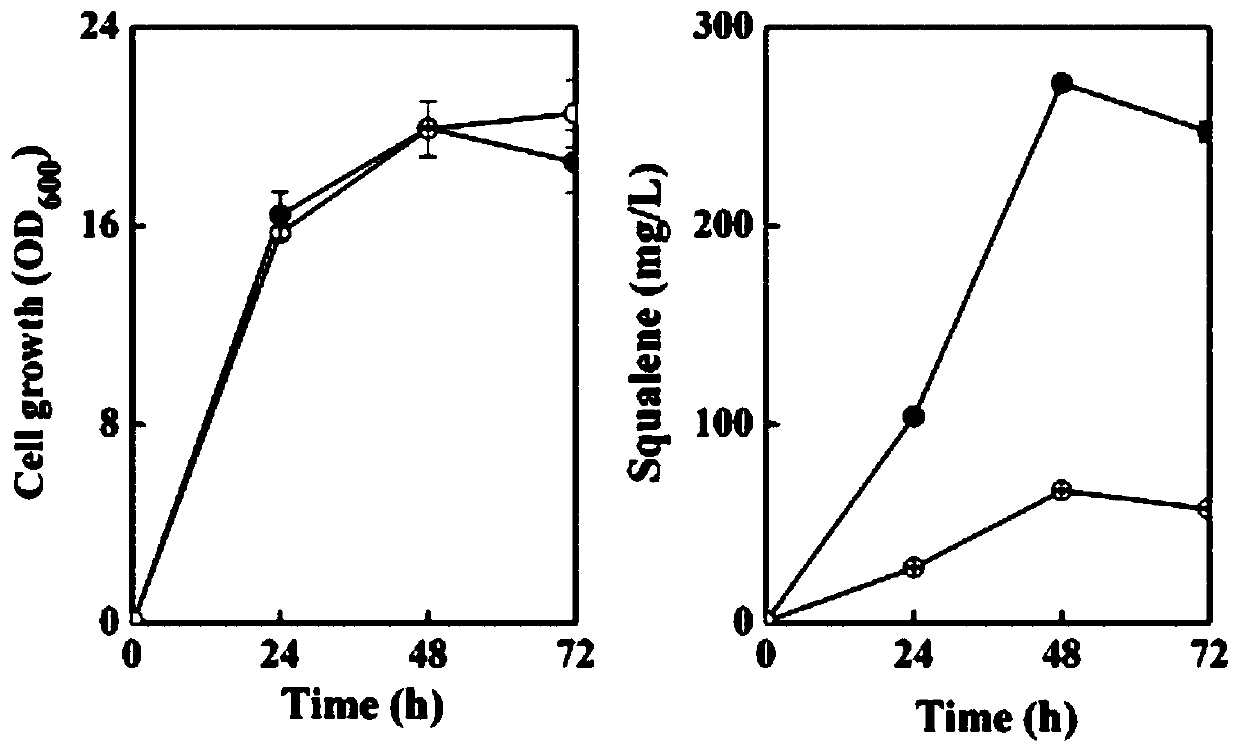

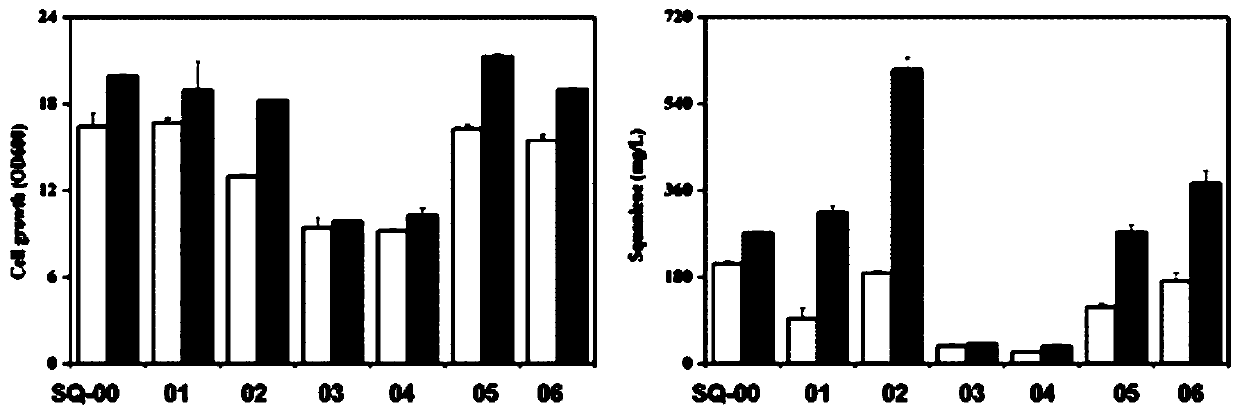

Squalene engineering strain, squalene synthetic plasmid, cell membrane space expansion plasmid and preparation methods

ActiveCN111518739AReduce dependenceReduce overexploitationBacteriaMicroorganism based processesEscherichia coliCell factory

The invention relates to a squalene engineering strain, a squalene synthetic plasmid, a cell membrane space expansion plasmid and preparation methods. By constructing an engineering strain of a squalene synthetic pathway, developing a microbial cell factory and constructing a squalene synthetic unit of a gene related to membrane area expansion, the biosynthesis and industrial production process ofsqualene is promoted. According to the squalene engineering strain, the squalene synthetic plasmid and the preparation methods thereof, a green synthetic method for synthesizing the squalene in escherichia coli can reduce dependence on natural resources and overdevelopment. Moreover, the method is relatively low in cost, can realize large-scale squalene production, and has huge economic benefits.

Owner:SUZHOU UNIV

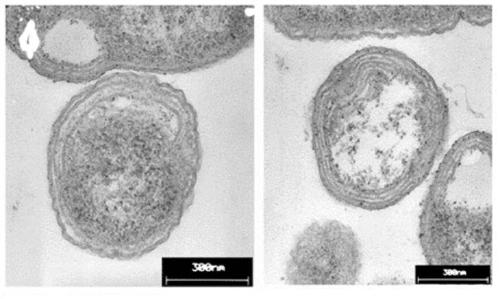

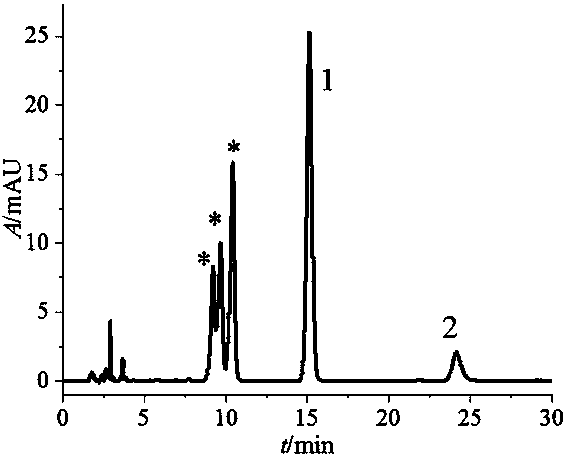

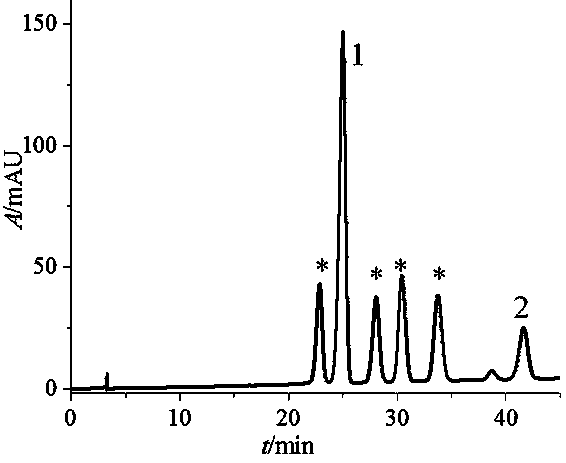

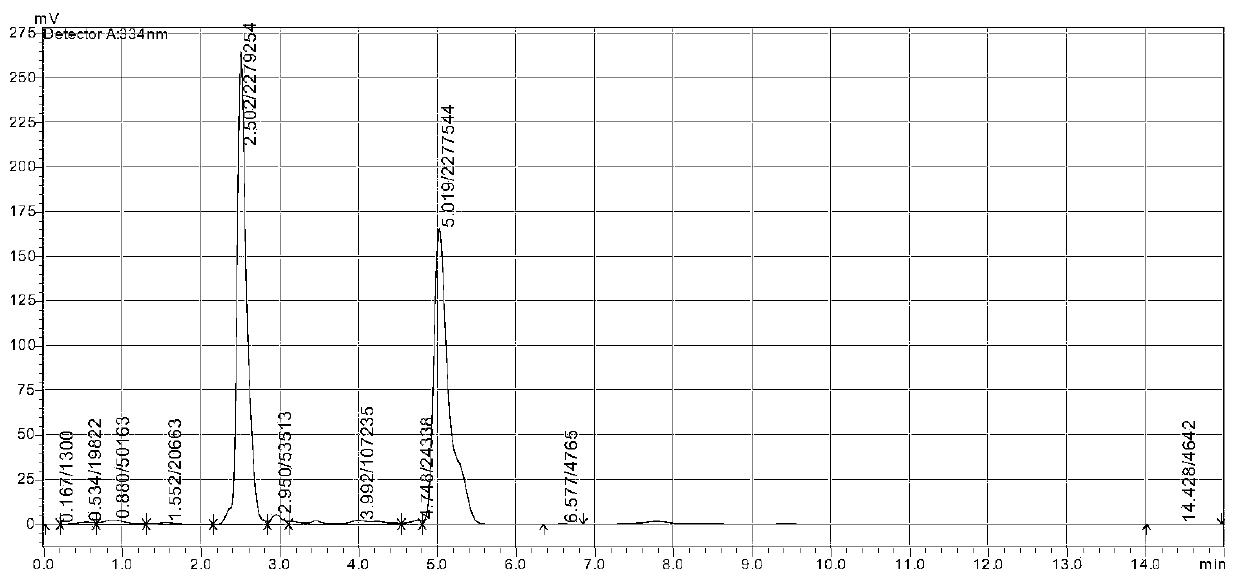

Method for preparation and purification of four stereoisomers of benzopyrene-DNA adduct

ActiveCN111116695ASynthesis Yield IncreasedEasy to separateSugar derivativesOrganic chemistry methodsChromatographic separationCombinatorial chemistry

The invention discloses a method for preparation and purification of four stereoisomers of a benzopyrene-DNA adduct. An in-vitro synthesis mode is adopted to synthesize the four stereoisomers of the benzopyrene-DNA adduct which is benzopyrene-7,8-dihydrodiol-9,10-epoxide-deoxyguanosine adduct (anti-BPDE-N<2>-dG), and through optimization of the in-vitro reaction conditions, the yield of the synthesized four stereoisomers of anti-BPDE-N<2>-dG is improved by more than 2 times when the method is compared with an existing synthesis method. A pi-hole effect is applied to chromatographic separationand purification of the stereoisomers for the first time, and the four stereoisomers can be separated completely in a short time through optimization of the chromatographic conditions, so that the chromatographic purification time is shortened greatly, and the purification efficiency is improved.

Owner:SHANXI MEDICAL UNIV

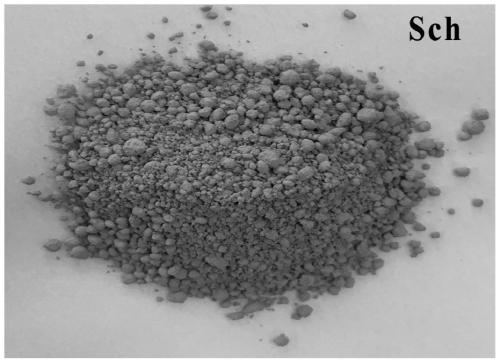

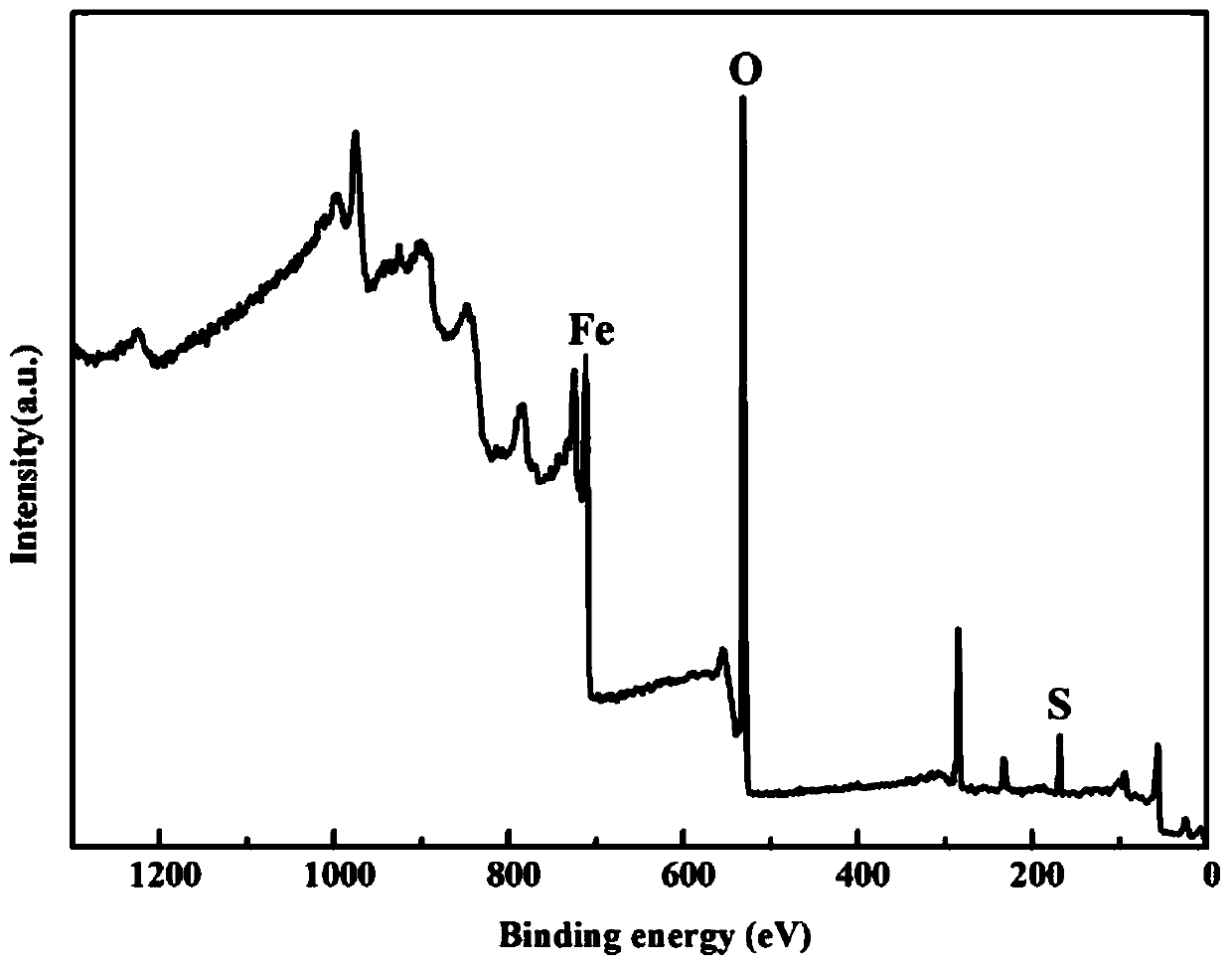

A kind of synthetic method and application of Schwittmannite

ActiveCN110152689BSynthesis Yield IncreasedReduce outputPhysical/chemical process catalystsOther chemical processesPtru catalystFreeze-drying

The invention discloses a synthesis method and application of Schwieterman stone, and belongs to the technical field of water treatment. The synthesis method of the Schwieterman stone comprises the following steps: (1) adding FeSO4.7H2O to an aqueous solution with a pH value of 2-7, performing even stirring, then adding H2O2, and then performing vibration treatment so as to form a precipitate; and(2) performing filtration and collection on the precipitate, performing washing with an acidic solution, and then conducting washing with deionized water, and performing vacuum freeze drying so as toobtain the solid catalyst Schwieterman stone. The yield of the Schwieterman stone prepared by using the method is high. When the prepared Schwieterman stone is used as a heterogeneous Fenton reactioniron-based material for Fenton-like oxidation reaction treatment on tetracycline, tetracycline in water can be removed effectively and efficiently, no secondary pollution to the environment is caused, the operation is simple, and the cost is low; and therefore a good application prospect is achieved in degradation of tetracycline pollutants in water.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for synthesizing valtrate by utilizing ceratobasidium sp.AG-A

InactiveCN106566848APromote biosynthesisIncrease profitMicroorganism based processesFermentationCulture fluidFermentation

The invention discloses a method for synthesizing valtrate by utilizing ceratobasidium sp.AG-A. The method comprises the following steps of (1) inoculating a solid culture medium with ceratobasidium sp.AG-A mycelia for inverse culture, and after mycelium germination, selecting contamination free fresh mycelia in the periphery and inoculating a fresh solid culture medium with the fresh mycelia for continuous inverse culture to obtain mature mycelia, wherein the used ceratobasidium sp.AG-A is a collected strain in the China general microbiological culture collection center (CGMCC) and has a collection number of CGMCC No.9817; (2) inoculating a seed culture medium with the mature mycelia obtained in the step (1), and performing shaking culture to obtain a seed solution; and (3) inoculating a fermentation culture medium with the seed solution obtained in the step (2) for performing fermentation culture, adding citronellal to the fermentation culture medium in batches in the fermentation culture process, and then continuing to perform shaking fermentation culture to obtain a valtrate-containing culture solution. According to the method, the yield of synthesizing the valtrate by the ceratobasidium sp.AG-A can be effectively increased.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

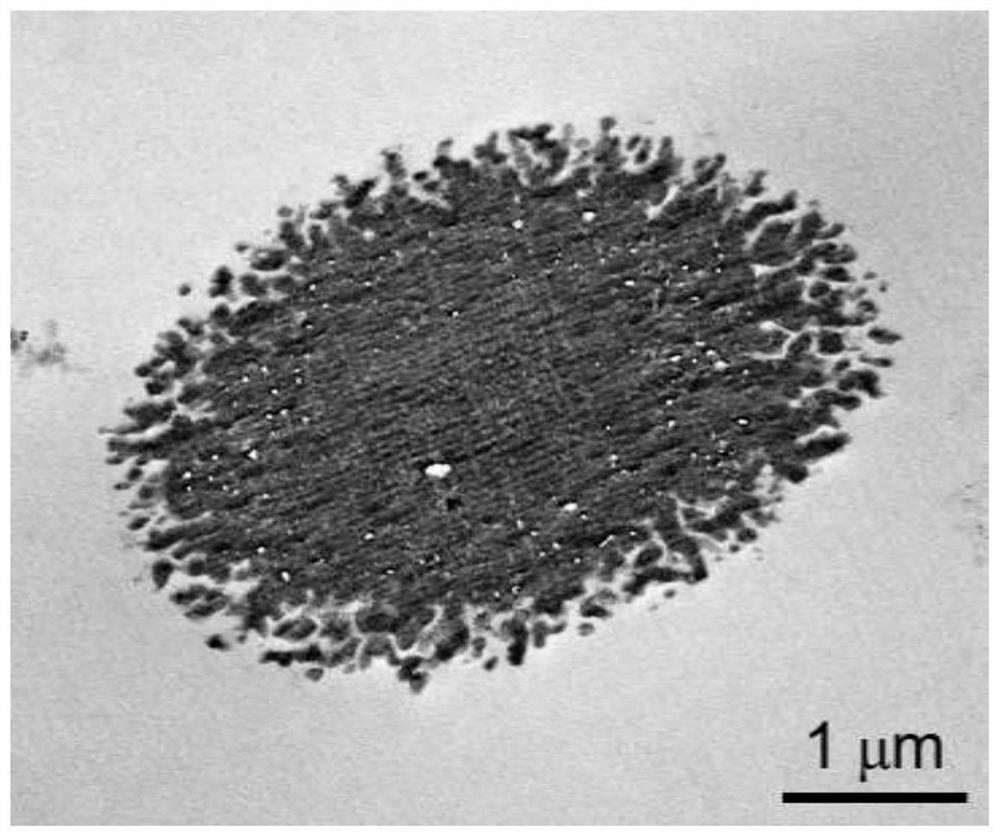

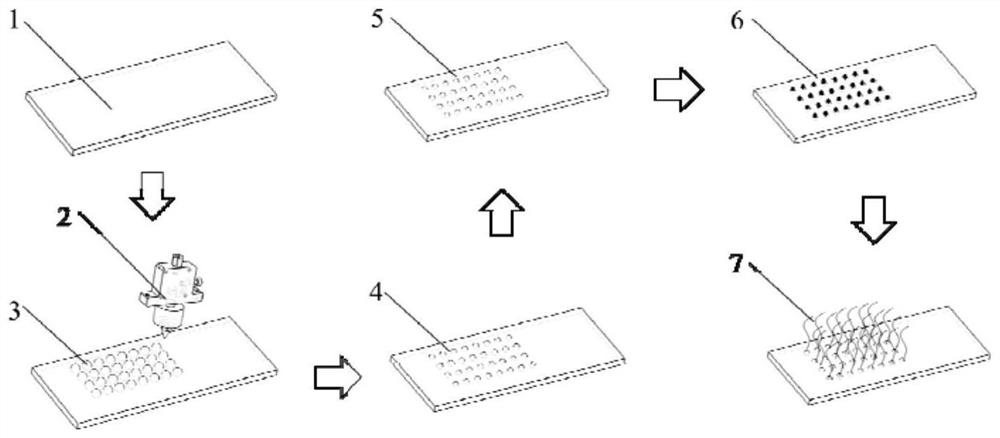

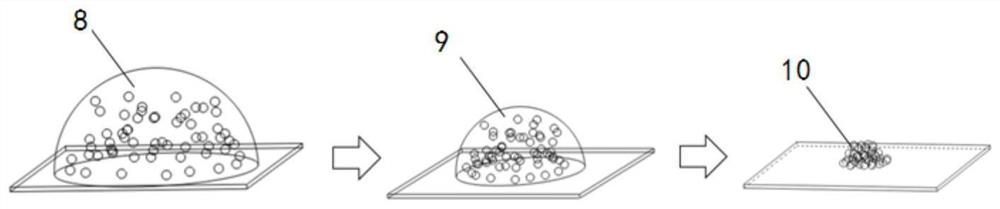

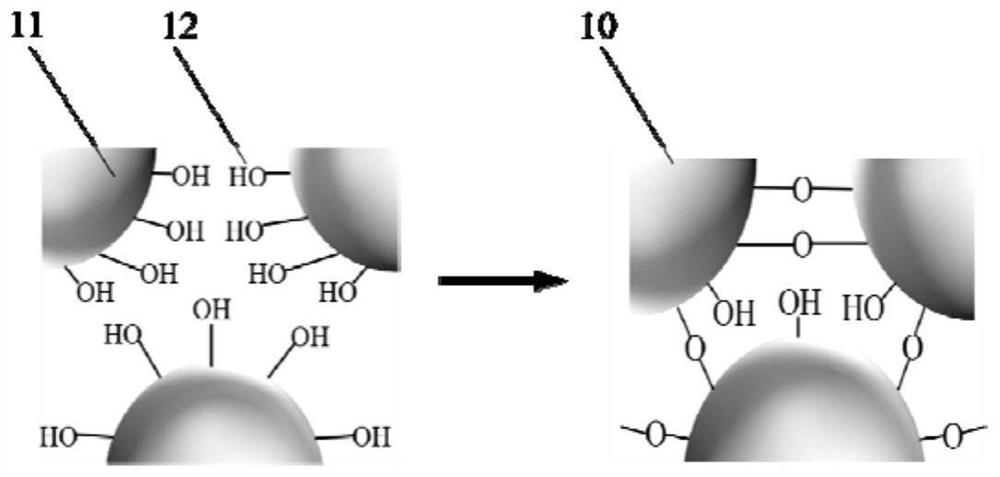

Microreactor array chip for nucleic acid synthesis and preparation method thereof

PendingCN114471397ASynthesis Yield IncreasedStrong physical bondBioreactor/fermenter combinationsBiological substance pretreatmentsMicroreactorOrganic synthesis

The invention provides a nucleic acid synthesis-oriented micro-reactor array chip and a preparation method thereof, the micro-reactor array chip with a high surface area is constructed by ink-jet printing of a nanoparticle droplet array on the surface of a synthetic chip and combination of a three-phase contact line regulation and control method and a high-temperature sintering technology at the same time, and the nucleic acid synthesis-oriented micro-reactor array chip is prepared. High-flux and high-load synthesis is realized, the overall synthesis yield of the synthetic chip is improved, and the method can be applied to the field of organic synthesis.

Owner:TIANJIN UNIV

18F-labelled quinazolines irreversible EGFR (epidermal growth factor receptor) positive electron tracer agent, as well as preparation method and application thereof

ActiveCN103656694BHigh yieldTroubleshoot Compositing DifficultiesOrganic chemistryMicrobiological testing/measurementChemical structureChemical synthesis

The invention discloses an 18F-labelled quinazolines irreversible EGFR (epidermal growth factor receptor) positive electron tracer agent, as well as a preparation method and application thereof. The 18F-labelled quinazolines irreversible EGFR positive electron tracer agent has a chemical structure represented by the formula II. The synthesized 18F-labelled small-molecular irreversible EGFR positive electron tracer agent has a clinical value for diagnosing and monitoring a treating effect and particularly plays an important role in pushing individual-based treatment. Furthermore, the invention further provides a one-step method for synthesizing the 18F-labelled small-molecular irreversible EGFR positive electron tracer agent. The method has the characteristics of multiple purposes, high yield, high efficiency, short synthesis time, low cost and the like and can meet a requirement on large-scale production.

Owner:HARBIN MEDICAL UNIVERSITY

Method for synthesizing 5-hydroxy beta-indolyl alanine by taking beta-indolyl alanine as substrate and application of 5-hydroxy beta-indolyl alanine

ActiveCN114875087ASynthesis Yield IncreasedIncrease productionBacteriaHydrolasesCombinatorial chemistryEnzyme

The invention provides a method for synthesizing 5-hydroxy beta-indolyl alanine by taking beta-indolyl alanine as a substrate and application of the 5-hydroxy beta-indolyl alanine. The 5-hydroxyl beta-indolyl alanine high-producing strain provided by the invention is used for a method for synthesizing 5-hydroxyl beta-indolyl alanine by a biological method by taking beta-indolyl alanine as a substrate, and the synthesis yield of the 5-hydroxyl beta-indolyl alanine is high. Through construction of a BH4 regeneration system and excavation of a new BH4 regeneration enzyme, the regeneration capacity of an engineering strain BH4 is enhanced, and especially the yield of biosynthesized 5-hydroxyl beta-indolyl alanine is remarkably increased under the simultaneous action of a double BH4 regeneration system.

Owner:河北维达康生物科技有限公司

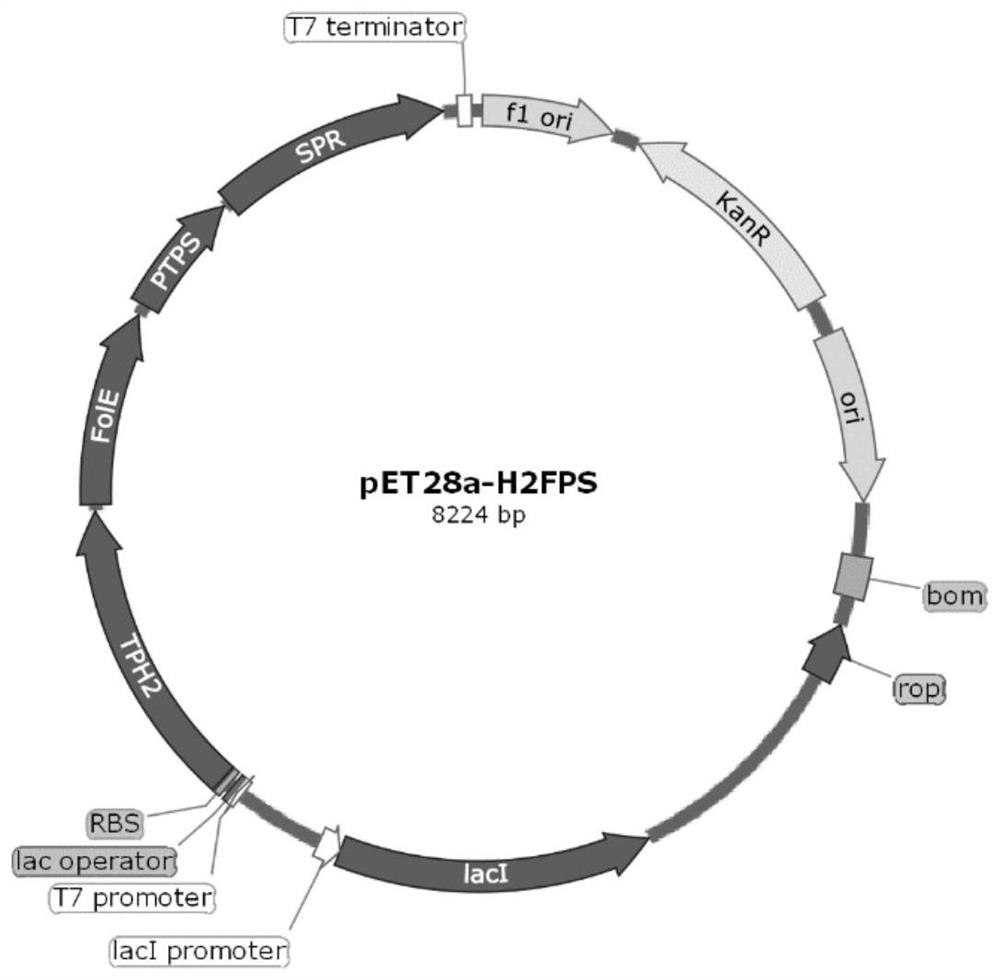

Method for increasing exogenous synthesis yield of water-soluble algal cyanine

ActiveCN110791534AIncreased yield of exogenous synthesisSynthesis Yield IncreasedBacteriaMicroorganism based processesBiotechnologyEscherichia coli

The invention discloses a method for increasing an exogenous synthesis yield of water-soluble phycocyanin, which belongs to the technical field of biological genetic engineering and microbial fermentation. According to the method, a TB culture medium is used as a contrast; an expression vector system is induced according to escherichia coli; the phycocyanin is synthesized by using the phycocyaninsynthase; the specific culture medium components and the culture temperature are selected, so that the synthesis yield of the water-soluble algae is greatly increased, the water-soluble algae producedby the method has the characteristic that the yield is 2.2 times higher than that of the water-soluble algae produced by control culture, and more efficient culture conditions are provided for the production of the water-soluble algae.

Owner:ANHUI NORMAL UNIV

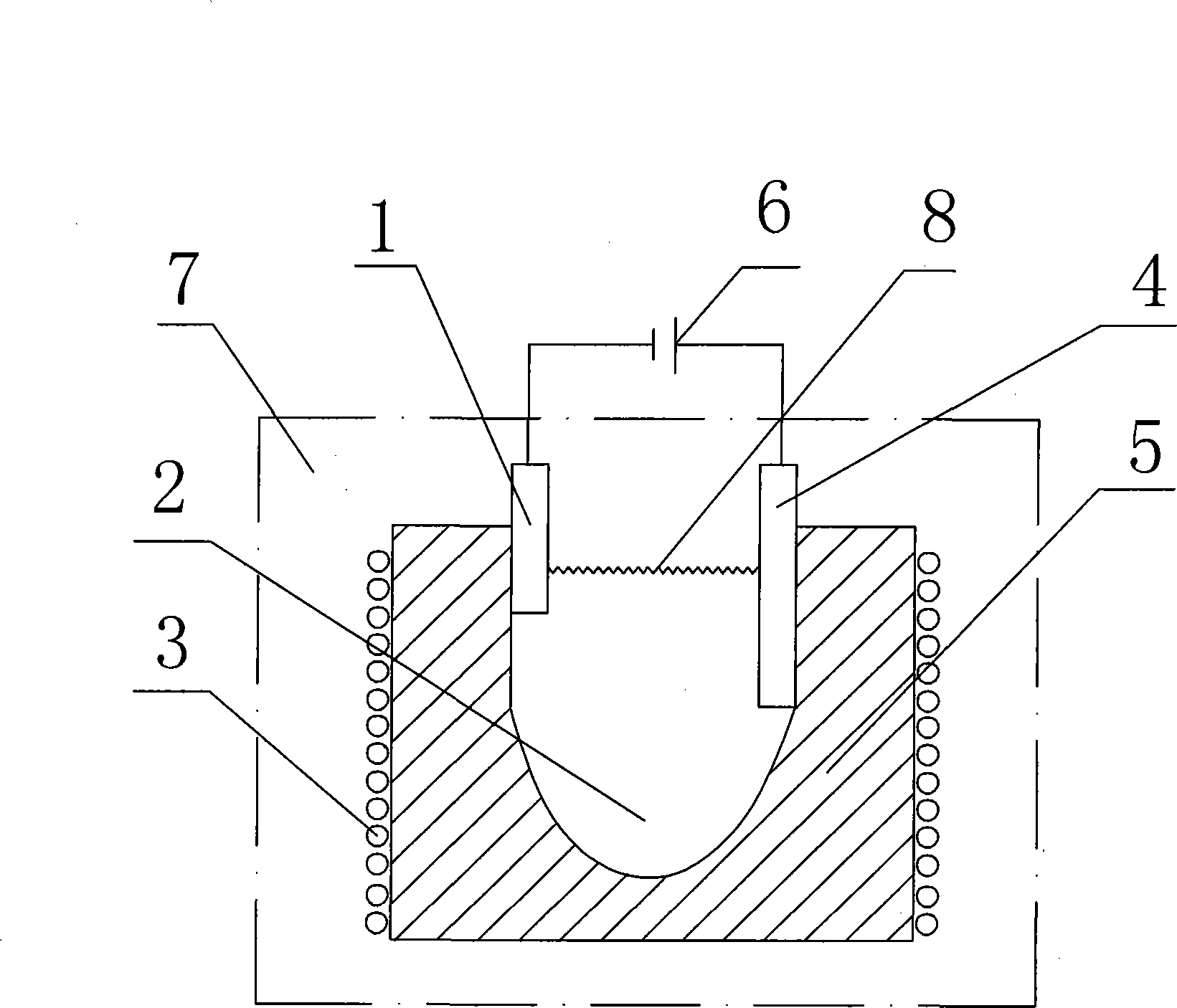

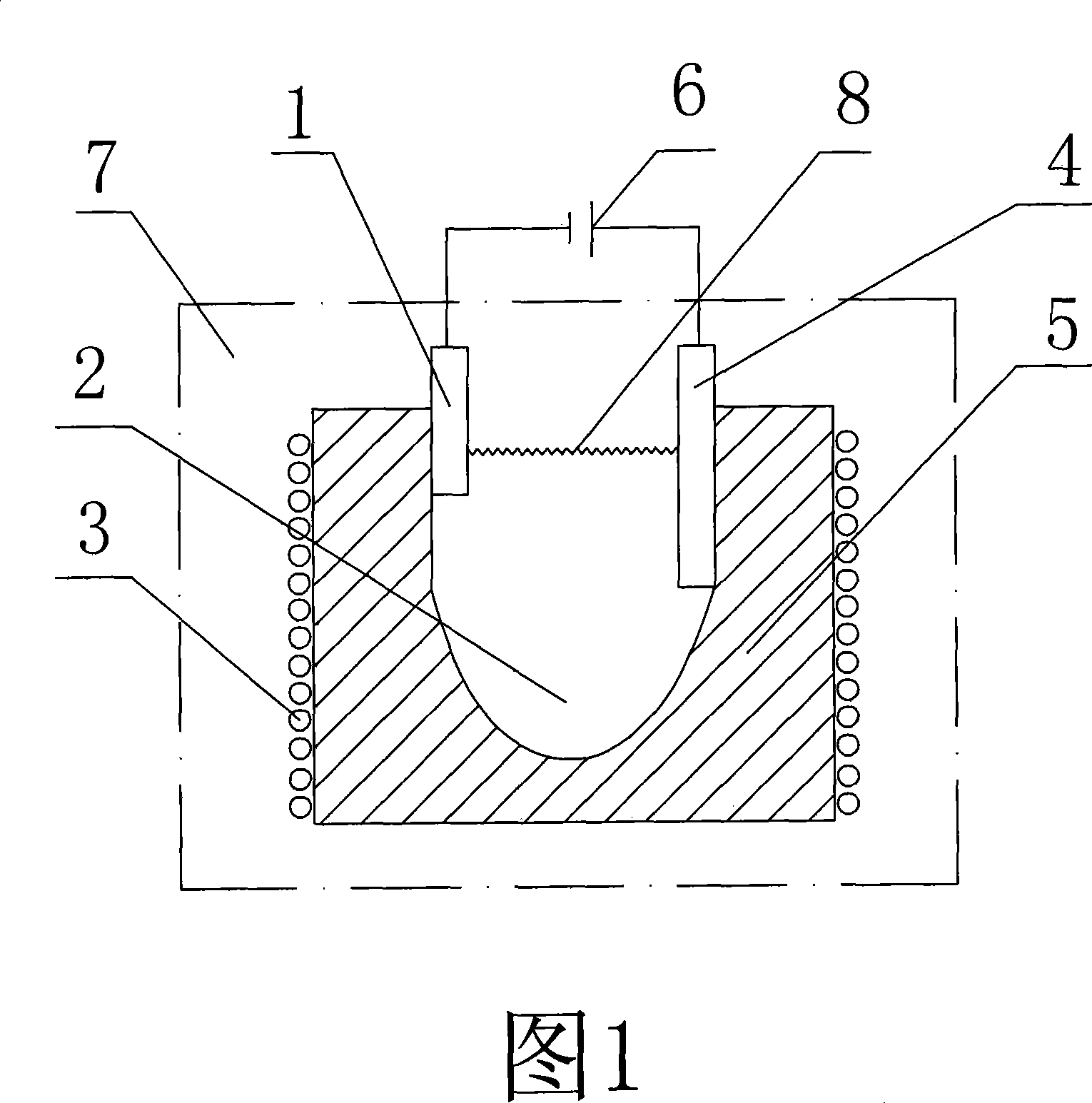

Electric plating synthesis method for diamond under atmospheric pressure

InactiveCN101307486BSynthesis Yield IncreasedQuality improvementPolycrystalline material growthSingle crystal growth detailsElectrolysisGas phase

The invention relates to a method for synthesizing diamonds, in particular to a method for synthesizing diamonds by electroplating at normal pressure. In the method, transition group metals and transition group metal alloys are added with carbons and put in a pot for melting, and under the normal pressure, the temperature of between 1000 and 1600 DEG C, the voltage of between 2 and 36V and the electric current of between 300A and 1800A, the mixture in the pot undergoes the electroplating for 1 to 800 minutes, and after powering-off, the cathode is taken out and undergoes electrolytic partially or acid alkali treatment to remove impurities, and finally diamonds are obtained. The method of the invention can accurate control such technical parameters of synthesis as temperature, voltage and current, etc. with low equipment investment, little energy consumption and simple process, greatly improve the quality of diamonds and resolve the problems of expensive equipment, unstable quality, low conversion rate, hard collection and high synthesis cost existing in the synthesis of diamonds made by prior static pressure methods, explosion methods, gas phase deposition synthesis methods, etc. In the invention, surface of electroplating liquid are covered by graphite powders or the pot is protected by vacuum or inert gases, so the diamonds with higher grade or jewel grade can be obtained.

Owner:郭朝林

18F-labeled quinazoline type EGFR (epidermal growth factor receptor) positron tracer, as well as preparation method and application thereof

ActiveCN103690972BHigh synthesis efficiencyIncrease concentrationOrganic chemistryMicrobiological testing/measurementChemical structureChemical synthesis

The invention discloses an 18F-labeled quinazoline type EGFR (epidermal growth factor receptor) positron tracer, as well as a preparation method and an application thereof and belongs to the field of chemical synthesis. The 18F-labeled quinazoline type EGFR positron tracer disclosed by the invention has a chemical structure as shown in a formula II. The synthesized 18F-labeled small molecular EGFR type positron tracer has clinical value of diagnosis and monitoring of treatment curative effect and particularly plays an important role in promoting personalized treatment. In addition, the invention further provides the method for full-automatic synthesis of the 18F-labeled quinazoline type EGFR positron tracer by one step, the method has the characteristics of multiple purposes, large yield, high efficiency, short synthesis time, low cost and the like, and the requirements of large-scale production can be further met.

Owner:HARBIN MEDICAL UNIVERSITY

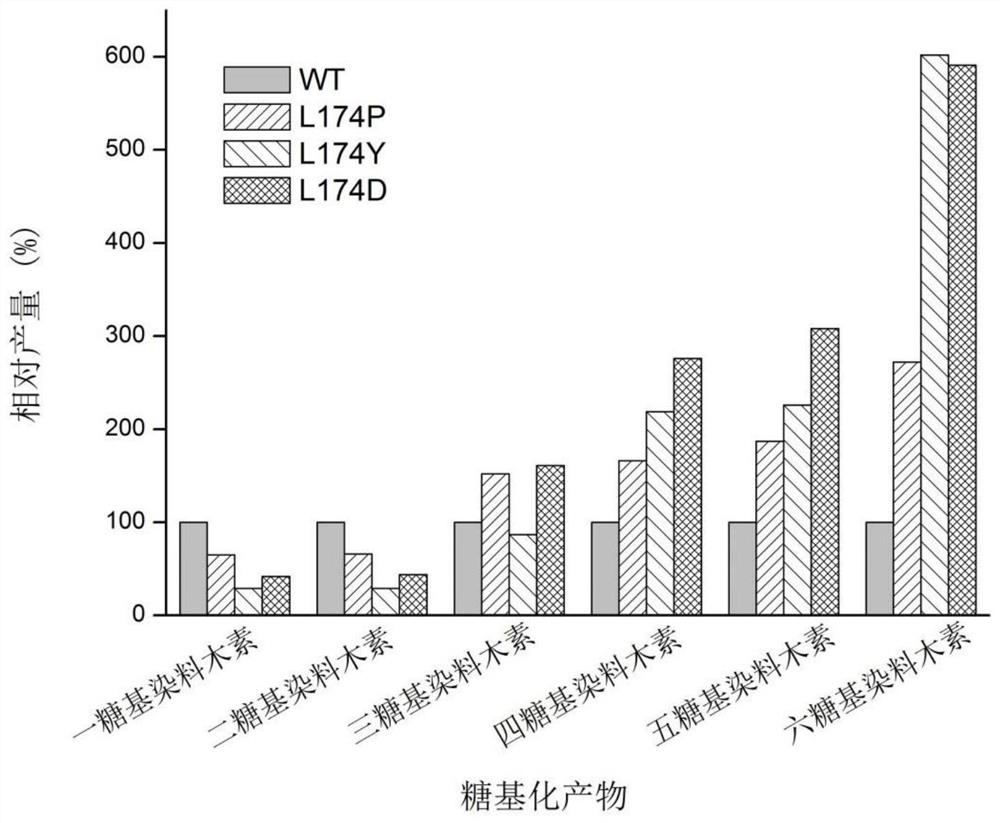

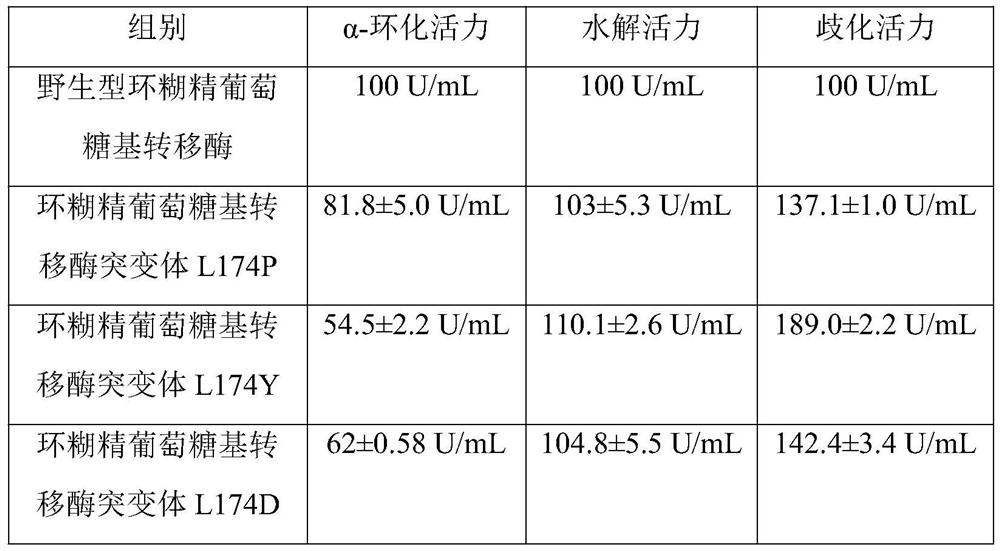

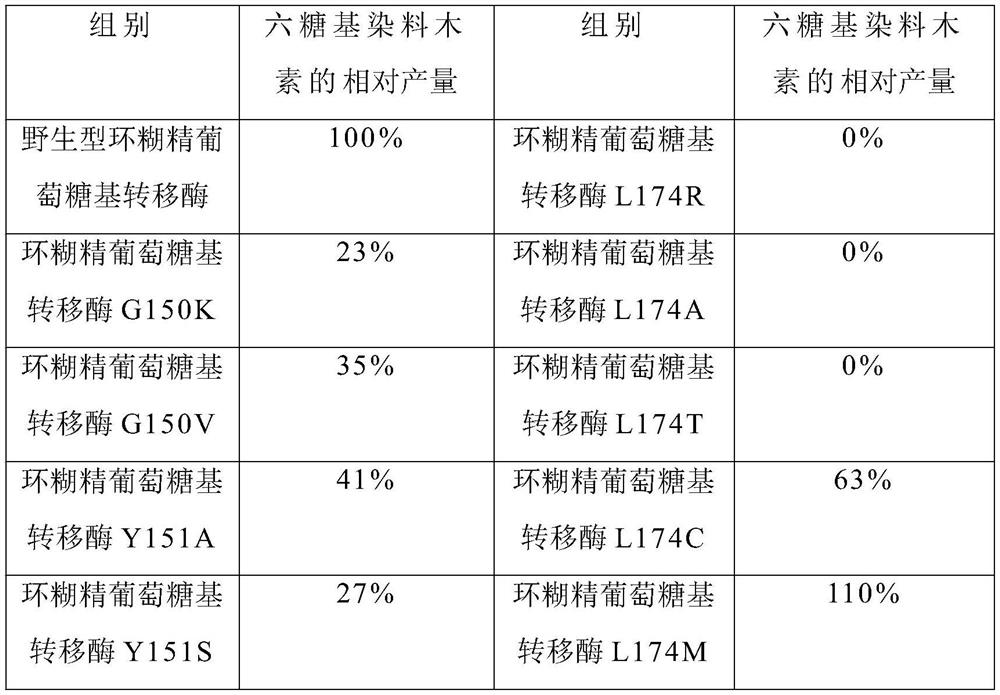

A cyclodextrin glucosyltransferase with improved product specificity and preparation method thereof

ActiveCN111394328BSynthesis Yield IncreasedEase of industrial productionBacteriaMicroorganism based processesCyclodextrinGenistein

The invention relates to a cyclodextrin glucosyltransferase with improved product specificity and a preparation method, belonging to the fields of genetic engineering and enzyme engineering. The present invention provides three cyclodextrin glucosyltransferase mutants L174P, L174Y and L174D with high genistein glycosylation efficiency. Compared with wild type cyclodextrin glucosyltransferase, they use maltodextrin as sugar When using the base donor to produce glycosylated genistein, the synthesis yield of long-chain glycosylated genistein increased by 0.7, 1.2 and 1.8 times, respectively, which is more conducive to the industrial production of glycosylated genistein.

Owner:JIANGNAN UNIV

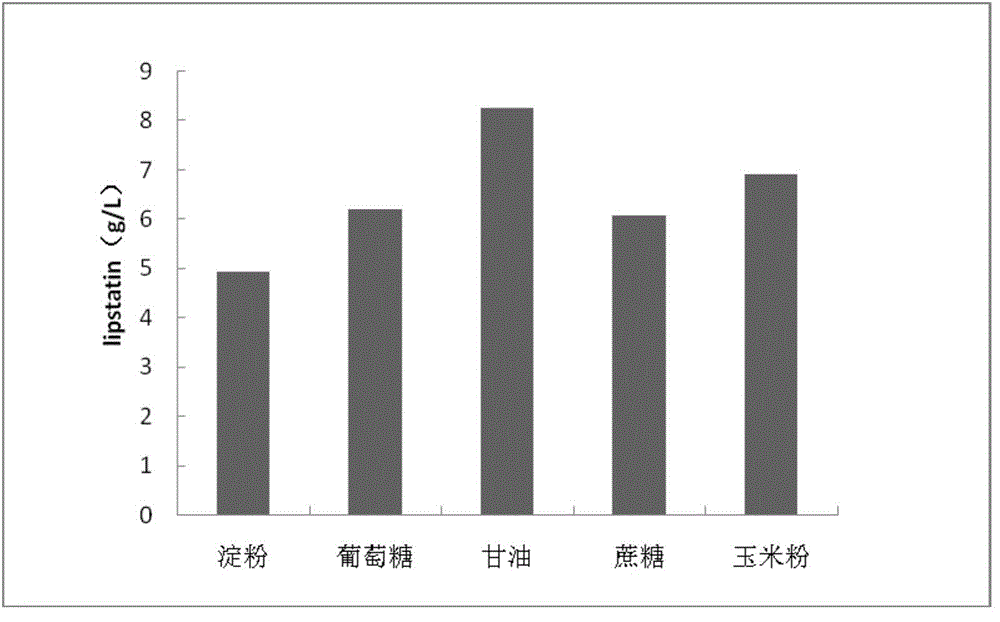

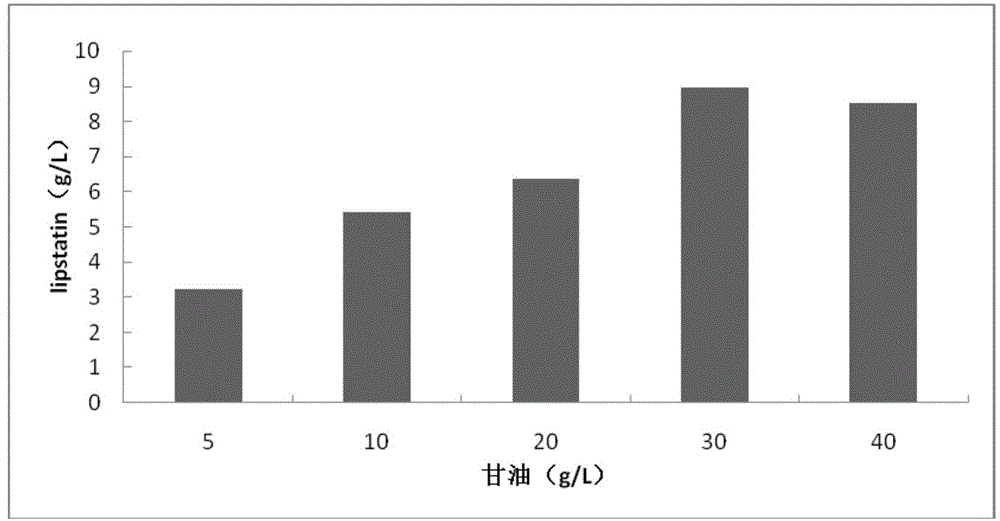

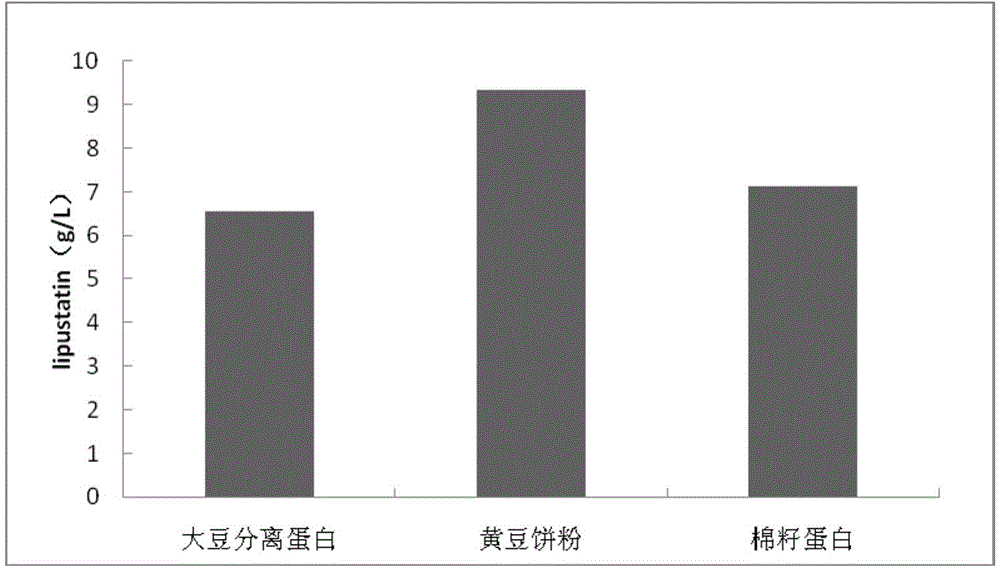

Streptomyces toxytricini for high yield of lipstatin and fermentation medium thereof

InactiveCN103555610BSynthesis Yield IncreasedEase of industrial productionBacteriaMicroorganism based processesStreptomyces toxytriciniMicrobiology

The invention provides streptomyces toxytricini for high yield of lipstatin, wherein the streptomyces toxytricini can high-efficiency utilize grease, and has a performance of high yield of lipstatin. On the other hand, the invention further provides an optimized streptomyces toxytricini fermentation medium.

Owner:BIOTOOL LLC

Ammonia-containing air purification method

InactiveCN108854451AAmmonia concentration is not requiredIncrease ammonia contentGas treatmentDispersed particle separationLiquid wasteCarbonization

The invention relates to an ammonia-containing air purification method, which comprises the following steps that (1) the flow of ammonia-containing air is guided to a tower bottom inlet of a sprayingabsorption tower through a draft fan; (2) the ammonia-containing air rises through the tower bottom inlet; at the moment, the tower top sprays soft water, so that the ammonia-containing air and soft water generate reverse flow contact; (3) in the reverse flow contact process, ammonia gas in the ammonia-containing air is completely dissolved into water and descends to the tower bottom along with the liquid; obtained purified air continuously rises to the tower top to be emitted into the air; (4) soft water after the ammonia gas absorption at the tower bottom is conveyed to the tower top again through a circulation pump; (5) the ammonia-containing air to be purified is supplemented again for contact absorption; the absorption process is repeated. Inorganized ammonia gas in the ammonia-containing air is collected to form dilute ammonia water waste liquid; the ammonia-containing air is purified; in addition, the dilute ammonia water waste liquid is used as supplementing water of a carbonization system; the resources are reasonably utilized.

Owner:绍兴凤登环保有限公司

Synthetic process of alkene monomer

InactiveCN102452875ASynthesis Yield IncreasedReduce manufacturing costOrganic chemistry methodsSolventDistillation

The invention discloses a synthetic process of alkene monomers. The synthetic process of alkene monomers comprises the following steps: dissolving raw materials in a solvent, well mixing, reacting to obtain a reaction product mixture, performing reduced-pressure distillation and washing, performing separation and drying to obtain the product. The invention smoothly synthesizes the product, has a high synthetic yield, and reduced production cost; the synthesized alkene monomers can be used to synthesize new polymer scale inhibitors with excellent anti-scaling performance for barium and strontium scale by way of homopolymerization or copolymerization.

Owner:袁俊海

18F labeled quinazoline class EGFR (Epidermal Growth Factor Receptor) positron tracer agent and preparation method and application thereof

ActiveCN103656693BHigh specific activityLow costOrganic chemistryIn-vivo radioactive preparationsChemical synthesisChemical structure

The invention discloses an 18F labeled quinazoline class EGFR (Epidermal Growth Factor Receptor) positron tracer agent and a preparation method and application thereof and belongs to the field of chemical synthesis. The 18F labeled quinazoline class EGFR positron tracer agent has a chemical structure as shown in a formula II. The synthesized 18F labeled micro-molecular EGFR class positron tracer agent has the clinic values of diagnosis and therapeutic effect monitoring and particularly plays an important role in promoting personalized treatment. Besides, the invention further provides a one-step method, namely a method for fully-automatically synthesizing the 18F labeled quinazoline class EGFR positron tracer agent. The method has the characteristics of multiple purposes, high yield, high efficiency, short synthesis time, low cost and the like and can meet the requirements of large-scale production. The formula II is shown below.

Owner:HARBIN MEDICAL UNIVERSITY

Trichlorosilane synthesis process and equipment

ActiveCN102390836BSynthesis Yield IncreasedReduce consumptionHalogenated silanesHydrogenSynthesis methods

The invention relates to a trichlorosilane synthesis process and equipment. The invention aims at disclosing an improved trichlorosilane synthesis method and equipment, which have the advantages of high yield and low cost and providing the method and equipment for continuously recycling byproducts, such as chlorosilane and silicon tetrachloride produced in the trichlorosilane synthesis process. The method comprises the following steps of: respectively separating chlorosilane and silicon tetrachloride from synthetic product materials by using a rectified separation method, gasifying the chlorosilane and the silicon tetrachloride and then introducing into a synthesis reactor, and enabling the chlorosilane content and the silicon tetrachloride content to reach a dynamic balance in the operation process. Therefore, according to the invention, the synthesis output of the trichlorosilane is improved, consumption of raw materials, hydrogen, chlorine gas and the like is reduced, and thus the production cost is reduced.

Owner:巴彦淖尔聚光硅业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com