A method for synthesizing two different grades of A-type zeolites by utilizing coal ashes

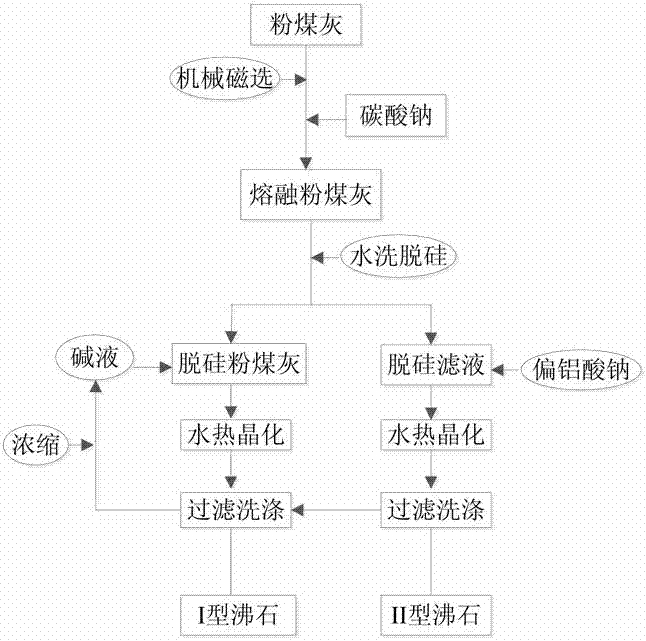

A technology for fly ash and zeolite, applied in the field of zeolite, can solve the problems of bottlenecks in purity, less than 50% utilization rate, environmental pollution, etc., and achieves the effects of large synthetic yield, overcoming low utilization rate and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

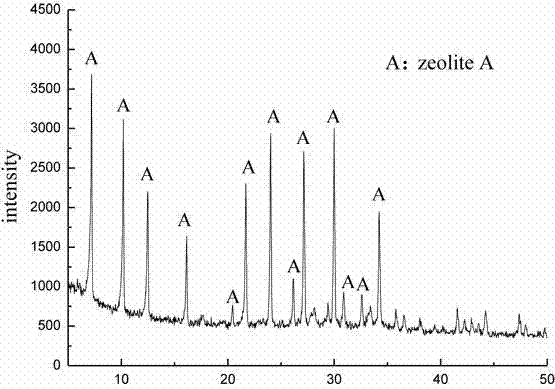

Embodiment 1

[0029] Accurately weigh 20 grams of raw coal fly ash, sieve the fly ash and go through magnetic separation for three times with a magnetic field strength of 700kA / m. Mix the fly ash after magnetic separation with solid sodium carbonate in proportion (1:1), roast at 800°C for 2 hours, and grind the molten product after cooling. The molten fly ash and water were mixed at a ratio of 1:30, placed in a glass container with constant temperature magnetic stirring for 1 h (rotating speed 200r / min, temperature 80°C), filtered and dried to obtain desiliconized fly ash. Mix the desiliconized fly ash with a certain concentration (2mol / L) of sodium hydroxide solution, stir vigorously for 1 hour, transfer the suspension into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and crystallize it at a temperature of 100°C 12 hours. After the reaction kettle is cooled to room temperature, the solid-liquid separation is carried out by suction filtration, washed with water until the p...

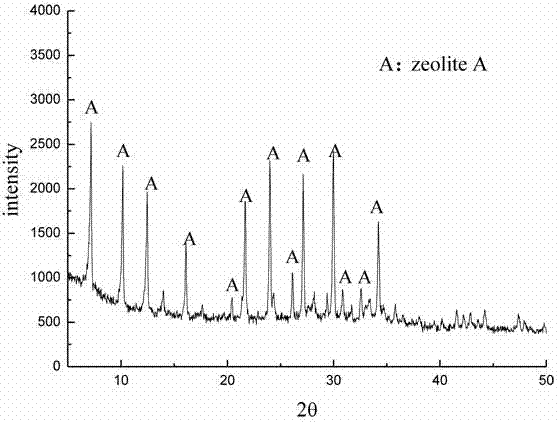

Embodiment 2

[0031] Accurately weigh 20 grams of raw coal fly ash, sieve the fly ash and go through magnetic separation for three times with a magnetic field strength of 700kA / m. Mix the fly ash after magnetic separation with solid sodium carbonate in proportion (1.2:1), roast at 750°C for 3 hours, and grind the molten product after cooling. The molten fly ash and water were mixed in a ratio of 1:20, placed in a glass container with constant temperature magnetic stirring for 1 h (rotating speed 200r / min, temperature 80°C), filtered and dried to obtain desiliconized fly ash. Mix the desiliconized fly ash with a certain concentration (3mol / L) of sodium hydroxide solution, stir vigorously for 1 hour, transfer the suspension into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and crystallize it at a temperature of 90°C 8 hours. After the reaction kettle is cooled to room temperature, the solid-liquid separation is carried out by suction filtration, washed with water until the p...

Embodiment 3

[0033]Accurately weigh 20 grams of raw coal fly ash, sieve the fly ash and go through magnetic separation for three times with a magnetic field strength of 700kA / m. Mix the fly ash after magnetic separation with solid sodium carbonate in proportion (1.5:1), roast at 700°C for 4 hours, and grind the molten product after cooling. The molten fly ash and water were mixed at a ratio of 1:10, placed in a glass container with constant temperature magnetic stirring for 1 h (rotating speed 200r / min, temperature 80°C), filtered and dried to obtain desiliconized fly ash. Mix desiliconized fly ash with a certain concentration (4mol / L) of sodium hydroxide solution, stir vigorously for 1 hour, transfer the suspension into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and crystallize it at a temperature of 80°C 4 hours. After the reaction kettle is cooled to room temperature, the solid-liquid separation is carried out by suction filtration, washed with water until the pH is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com