Trichlorosilane synthesis process and equipment

A technology of trichlorosilane and synthesis equipment, which is applied in the direction of silicon halide compounds, halosilanes, etc., and can solve problems such as waste and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

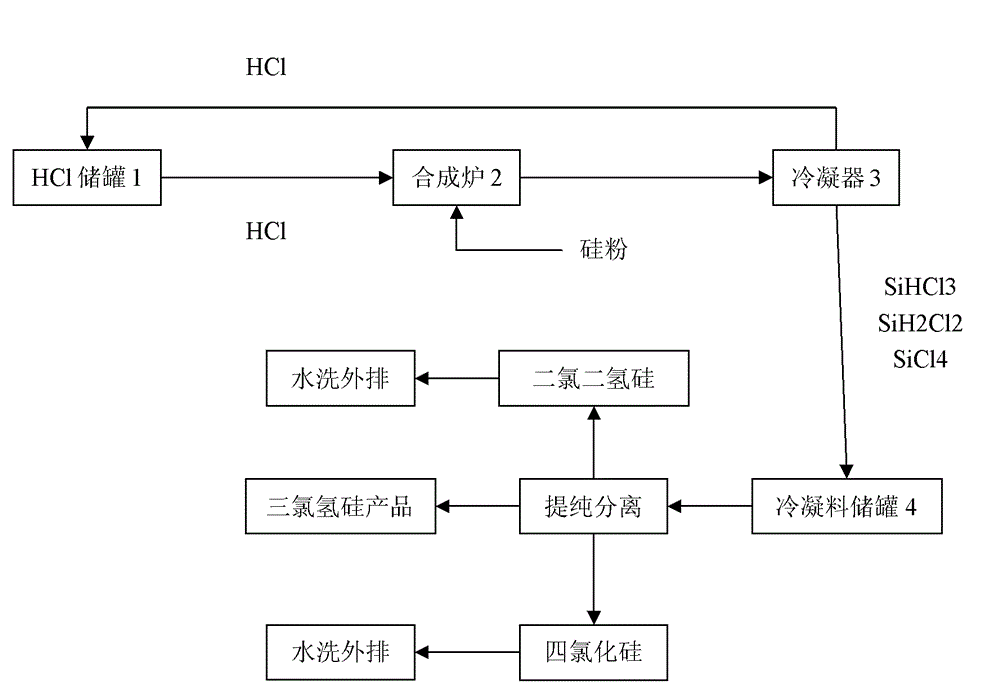

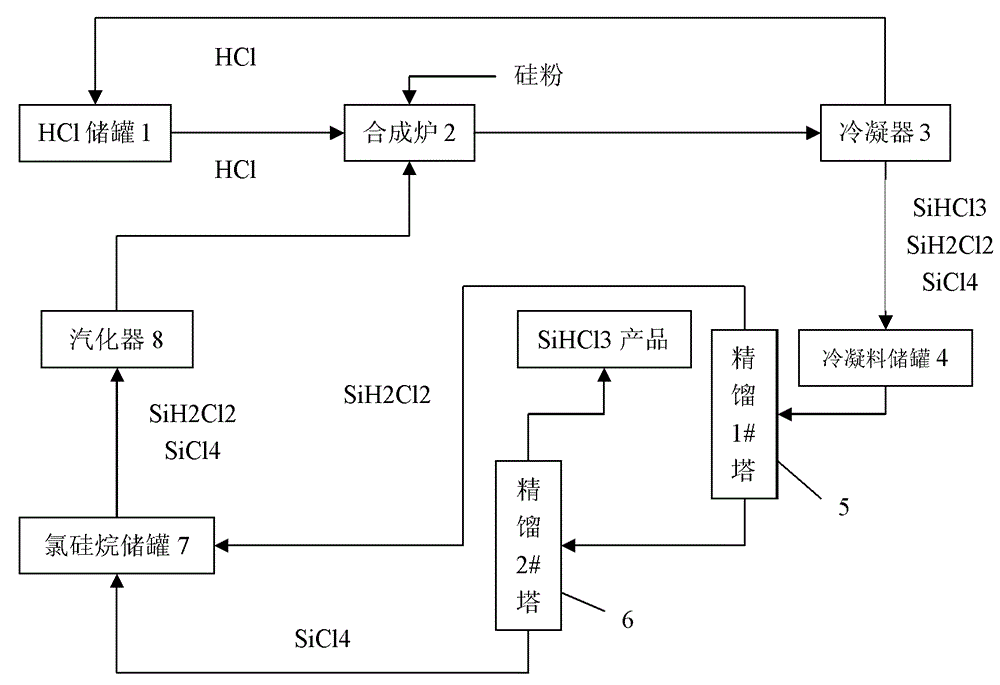

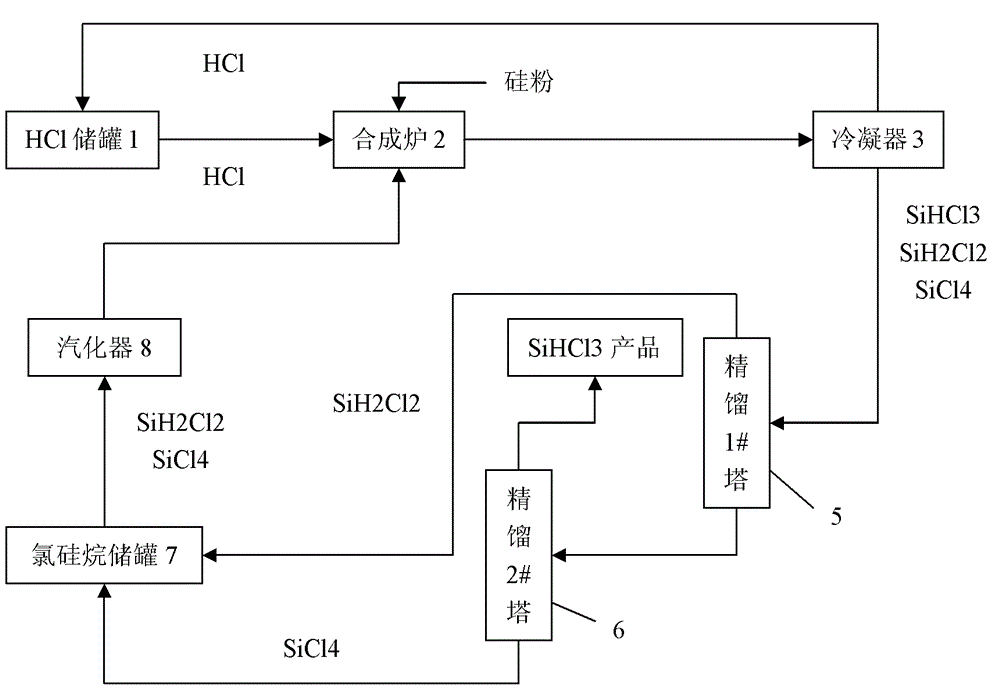

[0030] figure 1 One embodiment of the improved trichlorosilane synthesis apparatus of the present invention is shown. The equipment comprises: an HCl storage tank 1 for storing the HCl gas required for the reaction; a trichlorosilane synthesis furnace 2 connected in fluid communication with the HCl storage tank 1; a condenser 3 connected in fluid communication with the synthesis furnace 2, condensing The liquid phase outlet of the device 3 is connected to the condensate storage tank 4 in fluid communication, and its gas phase outlet is connected to the HCl storage tank 1 in fluid communication; the rectification 1# tower 5, its feed inlet is connected to the condensate storage tank 4 through a pipeline Rectification 2# tower 6, its feed inlet links to each other with the tower bottom of rectification 1# tower 5 through pipeline; Chlorosilane storage tank 7, with the tower top of rectification 1# tower 5 and rectification 2# tower 6 The bottom of the tower is respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com