Single crystal synthetic diamond material via chemical vapour deposition

A diamond and single crystal technology, applied in the field of synthesis of single crystal CVD synthetic diamond material layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As described in the Summary of the Invention section of this specification, the key to the realization of the present invention is the provision of methods which achieve a single crystal CVD diamond product material with high nitrogen content and low strain and birefringence.

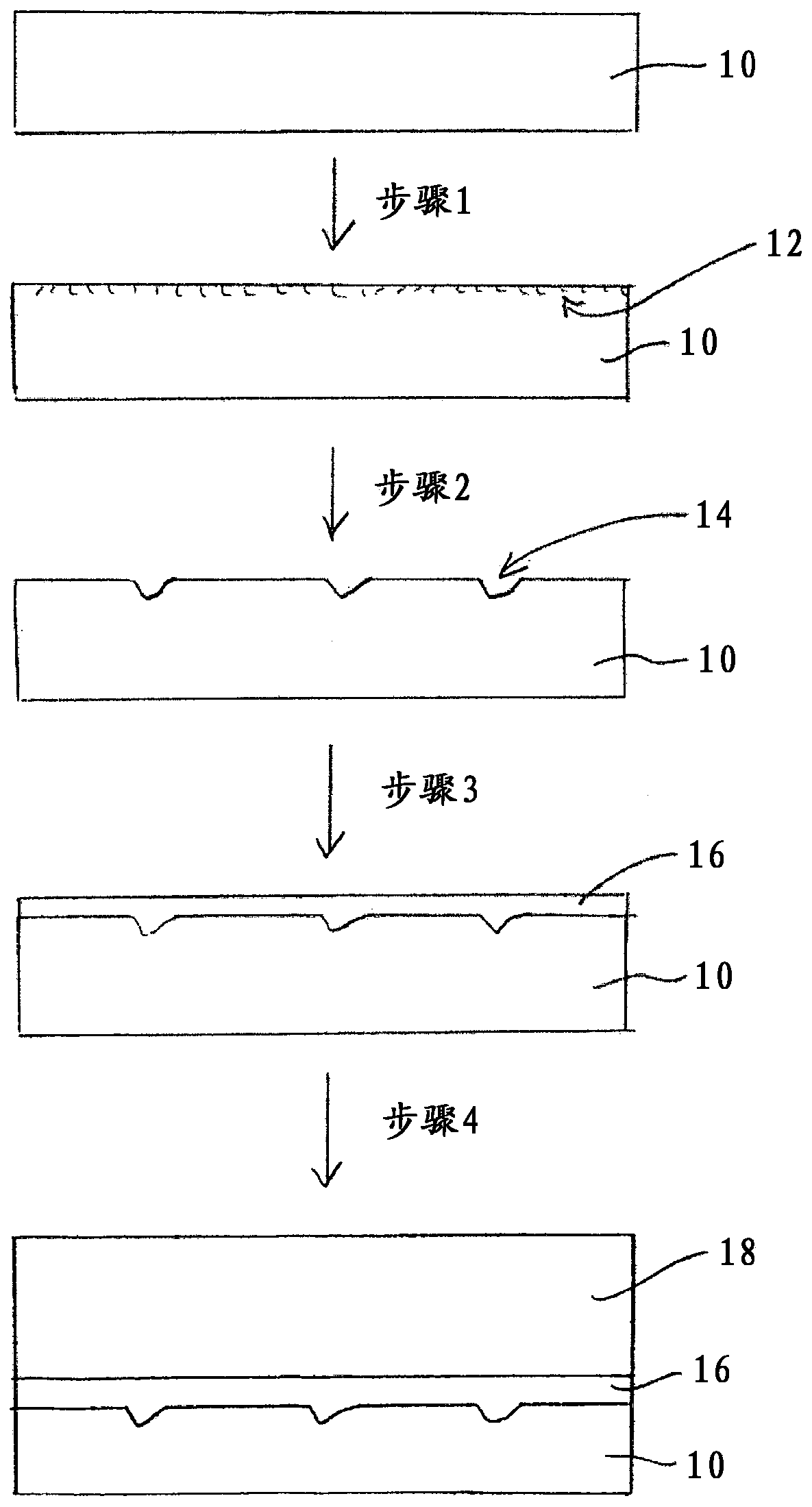

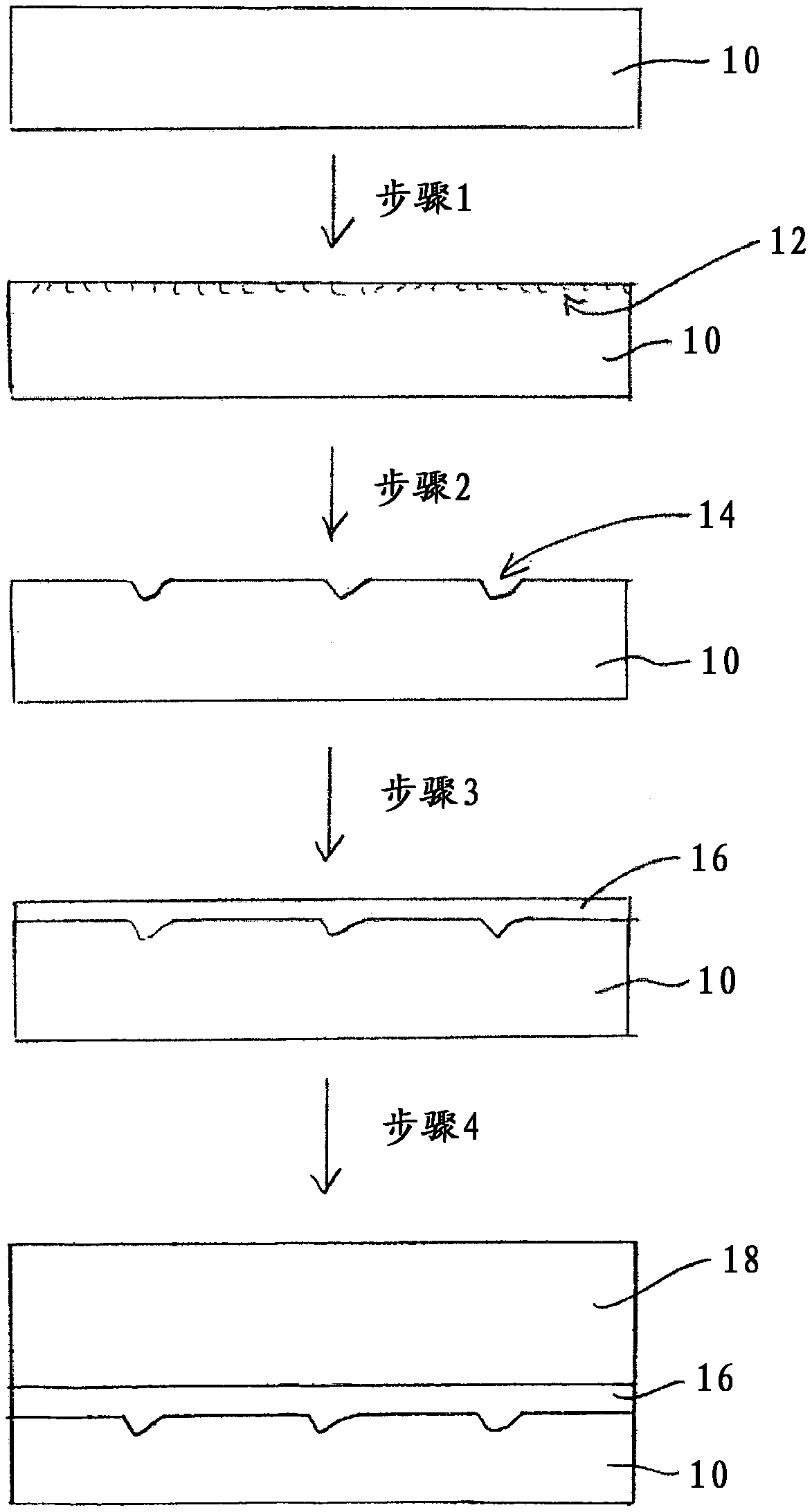

[0029] exist figure 1 The basic method is described in . In step 1, the substrate 10 is machined to a desired geometry and surface finish. Machining includes grinding to the desired thickness and then polishing to the desired surface roughness and flatness. Such machining produces surface and subsurface damage 12 to the growth surface of substrate 10 . Such surface and subsurface damage 12 can nucleate dislocations and generate strain in single crystal CVD diamond material grown on such surfaces. Therefore, in step 2 an etching method is applied to the growth surface 10 of the substrate to remove this damage. While this etching method removes surface and subsurface damage, it also causes pits...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com