Electric plating synthesis method for diamond under atmospheric pressure

A technology for synthesizing diamond and normal pressure, applied in the field of synthetic diamond, can solve the problems of inability to directly and stably control the synthesis temperature and pressure, unstable diamond output, quality, and inability to meet requirements, etc., achieving easy operation, reducing oxidation inclusions, and equipment investment. reduced effect

Inactive Publication Date: 2010-08-18

郭朝林

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these methods have certain shortcomings: the use of static pressure method to synthesize diamond requires high-voltage equipment and high-current electrical equipment to spontaneously heat. The general heating temperature is 1200°C-1600°C and the pressure is 4Gpa-100Gpa. Most of them use catalysts. Some use carbon nanomaterials to convert graphite into diamond; the diamond synthesized by this method is the main body of diamond used in industry. The disadvantage is that the equipment is expensive, and the actual pressure is difficult to draw from the high-pressure chamber, and the temperature is also the same, so it cannot be directly stabilized. Control the technical parameters such as synthesis temperature and pressure, and the output and quality of synthetic diamonds are unstable

The explosion method uses the instantaneous high temperature and high pressure generated by the explosion to directly convert graphite into diamond; the size of this type of diamond is mostly nano-scale, but the disadvantages are low conversion rate, difficult collection, and high synthesis cost

The disadvantage is that the use area is narrow and cannot meet the requirements of many industrial fields

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

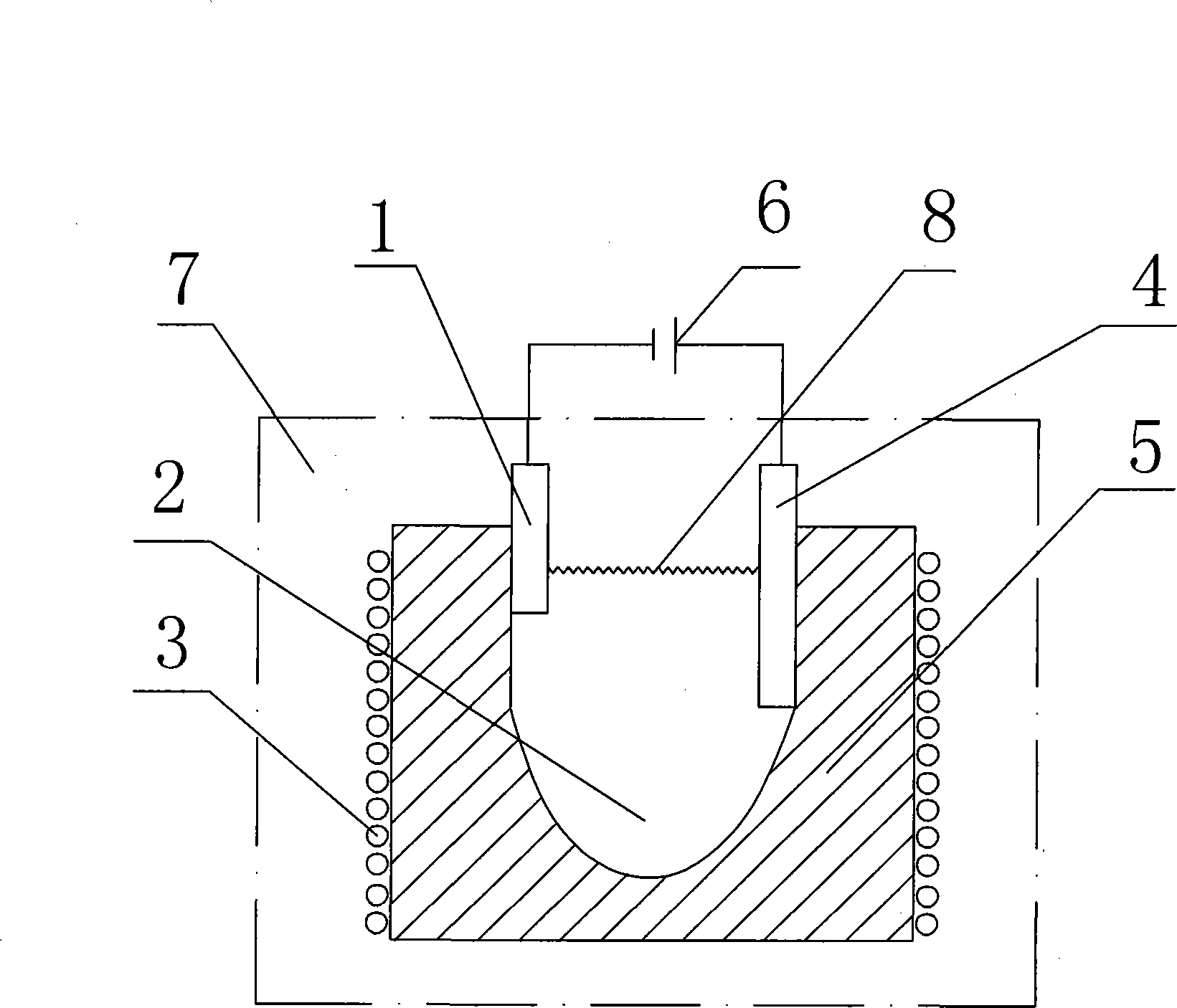

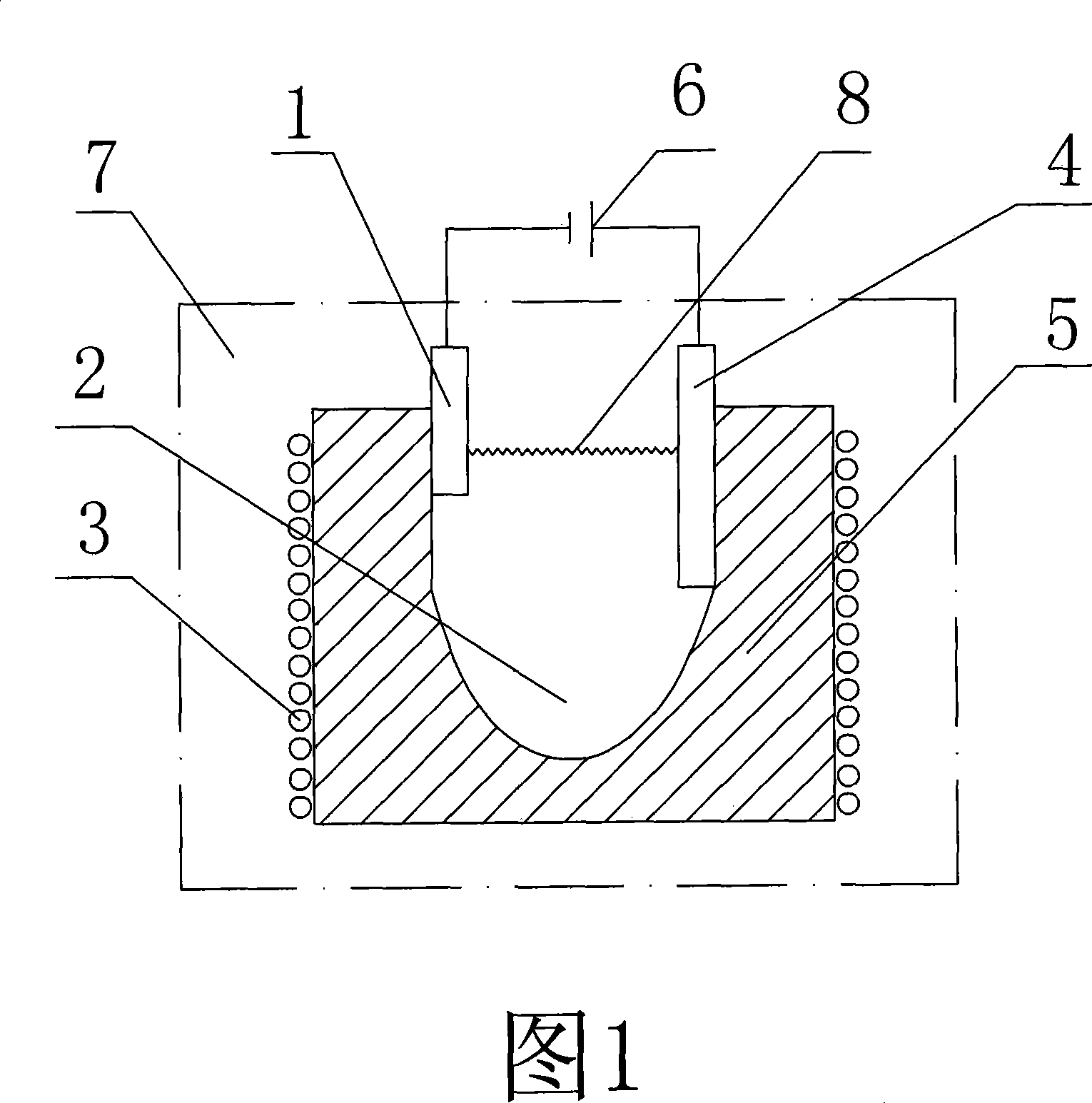

The invention relates to a method for synthesizing diamonds, in particular to a method for synthesizing diamonds by electroplating at normal pressure. In the method, transition group metals and transition group metal alloys are added with carbons and put in a pot for melting, and under the normal pressure, the temperature of between 1000 and 1600 DEG C, the voltage of between 2 and 36V and the electric current of between 300A and 1800A, the mixture in the pot undergoes the electroplating for 1 to 800 minutes, and after powering-off, the cathode is taken out and undergoes electrolytic partially or acid alkali treatment to remove impurities, and finally diamonds are obtained. The method of the invention can accurate control such technical parameters of synthesis as temperature, voltage and current, etc. with low equipment investment, little energy consumption and simple process, greatly improve the quality of diamonds and resolve the problems of expensive equipment, unstable quality, low conversion rate, hard collection and high synthesis cost existing in the synthesis of diamonds made by prior static pressure methods, explosion methods, gas phase deposition synthesis methods, etc. In the invention, surface of electroplating liquid are covered by graphite powders or the pot is protected by vacuum or inert gases, so the diamonds with higher grade or jewel grade can be obtained.

Description

Technical field: The invention relates to a method for synthesizing diamond, in particular to a method for electroplating and synthesizing diamond under normal pressure. Background technique: The hardest substance found in the world is diamond. Diamond has many special properties and uses, and has gradually become the material of choice for cutting, drilling, grinding, and special instrument components. At the same time, it is also widely used in industries such as mechanical processing, electronic appliances, optical glass, gemstone processing, and construction and building materials. Before the 1950s, only natural diamonds existed. In 1955, for the first time in human history, graphite ultra-high pressure synthetic diamonds were realized. After that, methods of synthetic diamonds such as static pressure method, explosion method, and vapor deposition synthesis method gradually appeared. . However, these methods have certain shortcomings: the use of static pressure method ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C30B29/04C30B30/02

Inventor 郭朝林郭雪

Owner 郭朝林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com