Method for constructing and optimizing ectoine producing engineering strain

A technology of ectoine and engineering bacteria, applied in the field of bioengineering, can solve problems such as difficult extraction, high cost, and long fermentation cycle, and achieve the effects of simple cultivation conditions, high production efficiency, and low equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

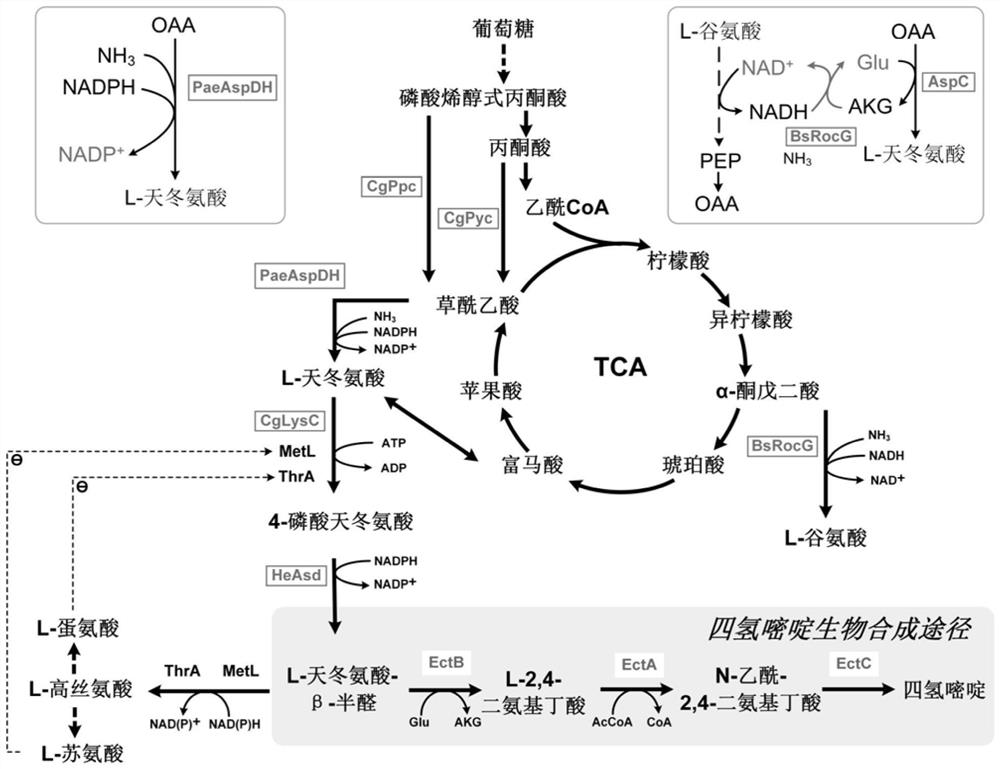

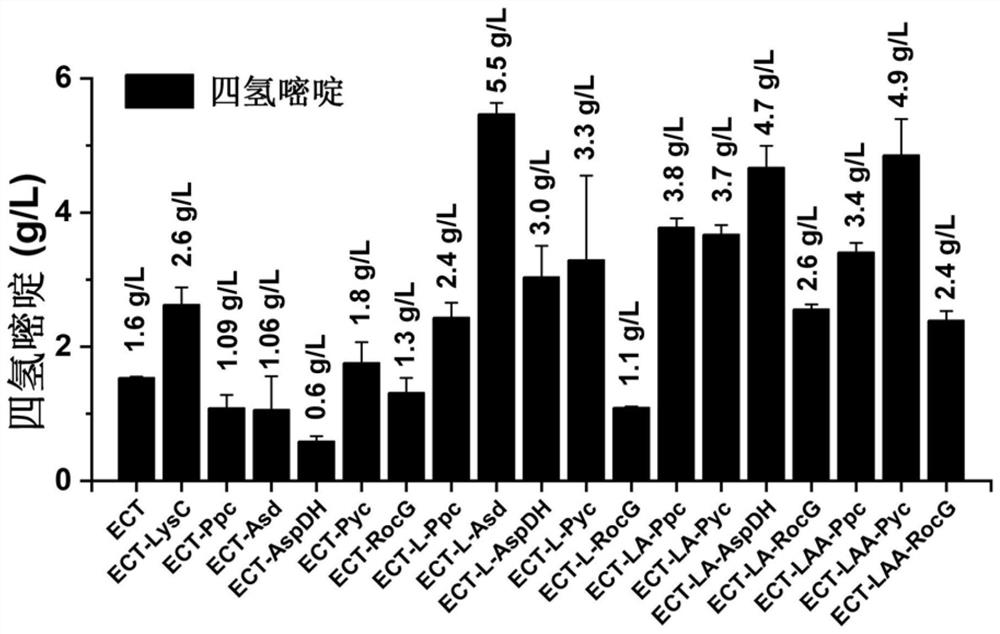

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: Construction of recombinant plasmid pRSF-Ect

[0071] (1) The ectopyrimidine synthesis gene cluster ectABC shown in SEQ ID NO.1 was synthesized by Jinweizhi Company.

[0072] (2) Extract plasmid pARSFDuet-1, design primers Ect-F1 / Ect-R1, and use plasmid pRSFDuet-1 as a template for PCR amplification to obtain a linearized vector.

[0073] Ect-F1: acgaccagaagccgctgtaacctcgagtctggtaaagaaaccg;

[0074] Ect-R1: ggctctgtggttgcgttcattatgtatatctccttcttatacttaactaatatactaagatgggg;

[0075](3) Ligate the fragments obtained in steps (1) and (2) with one-step cloning enzyme, mix the obtained recombinant vector with E.coli JM109 competent cells, and place in ice for 30 minutes.

[0076] (4) Rapidly heat-shock (42°C, 90s) the mixed system after the above-mentioned ice bath, then quickly place it on ice, let it stand for 2 minutes, then add 900 μL LB liquid medium without antibiotics in the sterile room, and restore the culture (40 -60min, 37°C, 220rpm).

[0077] (5...

Embodiment 2

[0078] Embodiment 2: recombinant bacterial strain ECT construction and batch fermentation

[0079] (1) Transform the recombinant plasmid pRSF-Ect obtained in Example 1 into E. coli BL21(DE3) competent cells to obtain the recombinant strain ECT.

[0080] (2) The ECT of the bacteria to be activated is taken from a glycerol tube stored at -80°C, streaked onto a kanamycin-resistant LB solid medium with a sterile inoculation loop, sealed and inverted, and cultured at a constant temperature of 37°C for 12-16 hours to a long time single colony.

[0081] (3) Pick a single colony from the activated LB plate and inoculate it into a 50 mL centrifuge tube containing LB medium (the volume of liquid is 5 mL), and culture at 37°C and 220 r / min for 8 hours to obtain the seed liquid.

[0082] The cultivated seed solution was transferred to a 250mL Erlenmeyer flask with a sample volume of 30mL in the batch fermentation medium at an inoculum size of 2% (v / v). The cultivation temperature was 30°...

Embodiment 3

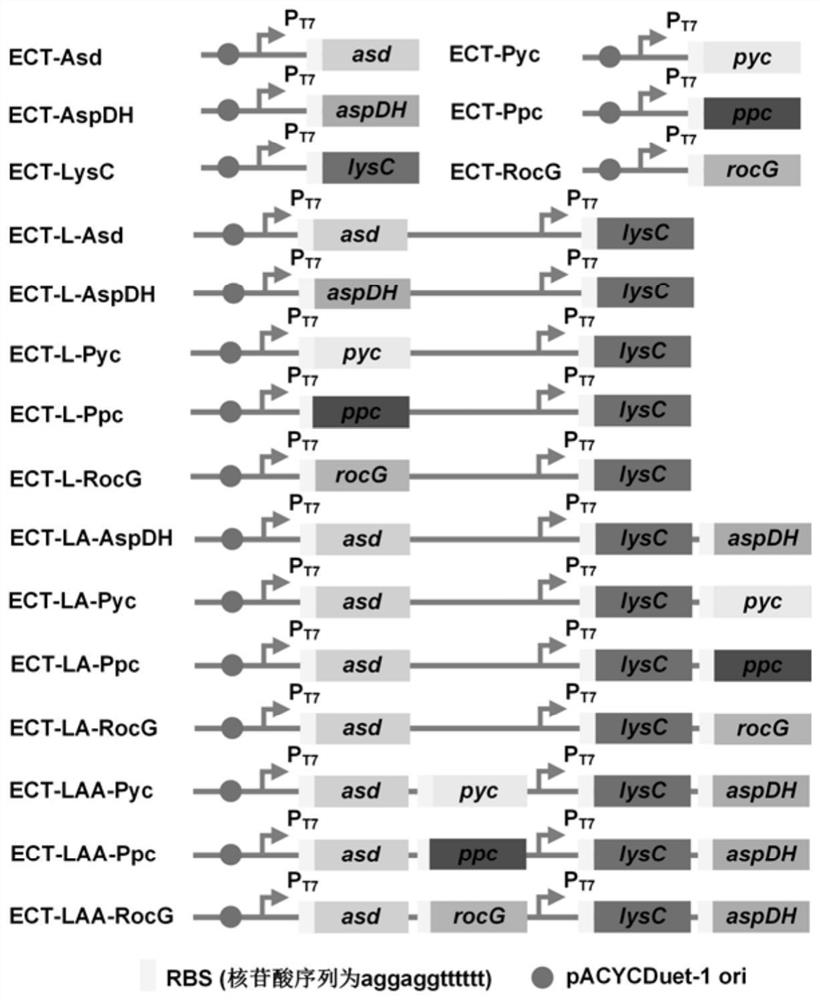

[0083] Example 3: Construction and verification of recombinant plasmid pACYC-LysC

[0084] (1) Genes ppc, pyc, aspDH, lysC shown in SEQ ID NO.2-7 C932T , asd, and rocG were synthesized by Jinweizhi Company.

[0085] (2) Extract plasmid pACYCDuet-1, design primers Ppc-F1 / Ppc-R1; Pyc-F1 / Pyc-R1; AspDH-F1 / AspDH-R1; LysC-F1 / LysC-R1; Asd-F1 / Asd-R1 ; RocG-F1 / RocG-R1, using the plasmid pRSFDuet-1 as a template, carried out PCR amplification to obtain a vector that achieves linearization at the expression frame of the second T7 promoter.

[0086] Ppc-F1: cgctgcgcaactccggctaggctgccaccgctgagcaataa;

[0087] Ppc-R1: tcgcgtaaaaaatcagtcataaaaaaacctccttatacttaactaatatactaagatggggaattgt;

[0088] Pyc-F1: tgatcgtcgtcgtttcctaagctgccaccgctgagcaataa;

[0089] Pyc-R1: ataacaattcccccatcttagtatattagttaagtataaggaggttttttcgtgtcgactcacacatcttc;

[0090] AspDH-F1: gcccacgcgatttcgatctaggctgccaccgctgagcaataa;

[0091] AspDH-R1: atcatgacgatattcagcataaaaaacctccttatacttaactaatatactaagatggggaattgttatccg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com