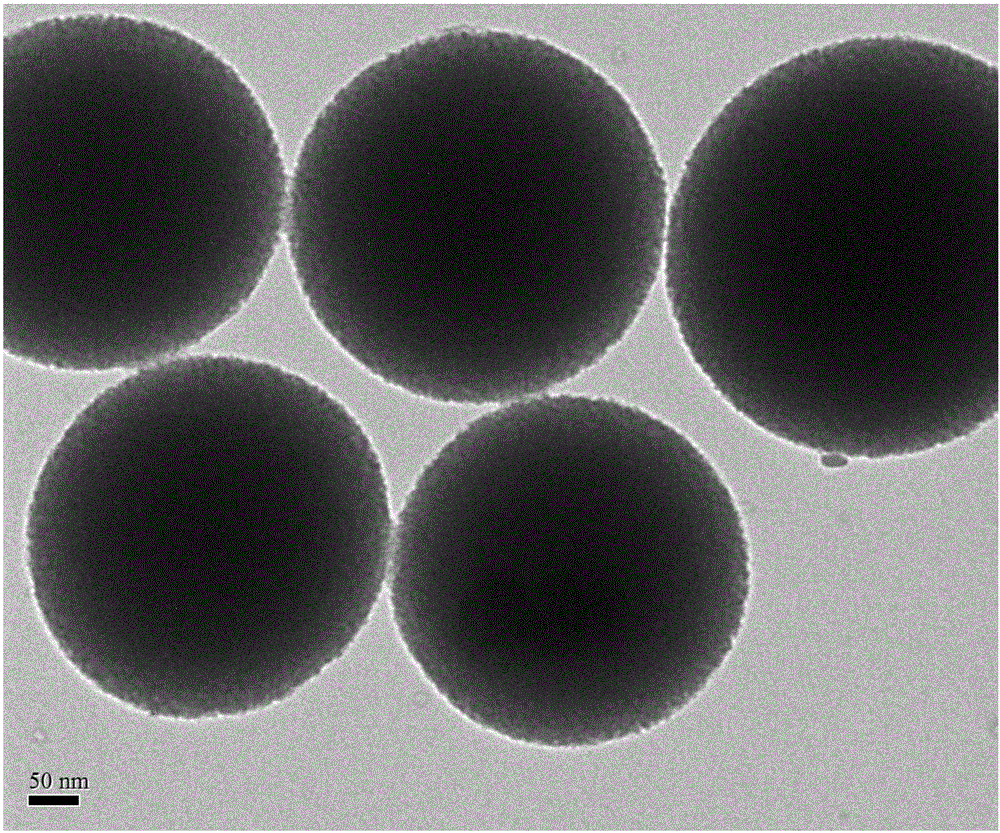

High-yield mesoporous silica nano-particle and folic acid targeting modification method thereof

A mesoporous silica and nanoparticle technology, applied in the field of medicine, can solve the problems of uneven particle size and low silica yield, and achieve the effect of simple synthesis process and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of synthetic method that utilizes sol-gel method to prepare high-yield silica nanoparticles, the concrete steps are as follows:

[0029] 1) Take a clean single-neck bottle, and prepare a solution of cetyltrimethylammonium bromide (CTAB) with a final concentration of 0.5% in it. 5 ml of absolute ethanol and 50 μl of ethylene glycol amine were added, heated at 80° C., and the reaction was stirred for 10 minutes under a magnetic force of 100 rpm. Measure 0.1 ml of ethyl orthosilicate in the single-necked bottle and heat at 80°C, under 100 rev / min magnetic conditions, stir and react for 10 minutes, then turn off the heating and then under 100 rev / min magnetic conditions, stir and react for 120 minutes. Immediately after the reaction was completed, centrifuge at 9,000 rpm for 5 minutes, and washed and precipitated with absolute ethanol once to obtain high-yield silica nanoparticles, which were stored after being vacuum-dried.

[0030] 2) Method for Mesoporous Silica ...

Embodiment 2

[0032] A kind of synthetic method that utilizes sol-gel method to prepare high-yield silica nanoparticles, the concrete steps are as follows:

[0033] 1) Take a clean single-neck bottle, and prepare a solution of cetyltrimethylammonium bromide (CTAB) with a final concentration of 0.6% in it. 6 ml of absolute ethanol and 60 microliters of ethylene glycol amine were added, heated at 75°C, and the reaction was stirred for 12 minutes under a magnetic force of 150 rpm. Measure 0.15 milliliters of ethyl orthosilicate in the single-necked bottle and heat at 75°C, under 150 rev / min magnetic conditions, stir and react for 12 minutes, then turn off the heating and then under 150 rev / min magnetic conditions, stir and react for 100 minutes. Immediately after the reaction was completed, centrifuge at 7,500 rpm for 4 minutes, and washed and precipitated twice with absolute ethanol to obtain high-yield silica nanoparticles, which were stored after being vacuum-dried.

[0034] 2) Method of M...

Embodiment 3

[0036] A kind of synthetic method that utilizes sol-gel method to prepare high-yield silica nanoparticles, the concrete steps are as follows:

[0037]1) Take a clean one-mouth bottle, and prepare a solution of cetyltrimethylammonium bromide (CTAB) with a final concentration of 0.7% into it. Add 7 ml of absolute ethanol and 70 microliters of ethylene glycol amine, heat at 80° C., and stir for 15 minutes under magnetic conditions of 200 rpm. Measure 0.2 ml of tetraethyl orthosilicate into a one-necked bottle, heat at 80°C, stir and react for 15 minutes under 200 rpm magnetic condition, then turn off the heating and then stir and react for 90 minutes under 200 rpm magnetic condition. Immediately after the reaction, centrifuge at 7,000 rpm for 3 minutes, and wash the precipitate with absolute ethanol 3 times to obtain high-yield silica nanoparticles, which are dried in vacuum and stored.

[0038] 2) Method for mesoporous silica nanoparticles Dissolve the silica nanoparticles in 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com