Preparation method of carbon-titanium dioxide chromatography stationary phase with shell-core structure and application

A chromatographic stationary phase and core-shell structure technology, applied in the field of stationary phase preparation, can solve the problems of high column efficiency, high density of metal oxide microspheres, etc., and achieve strong repeatability, good synthesis effect, and good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

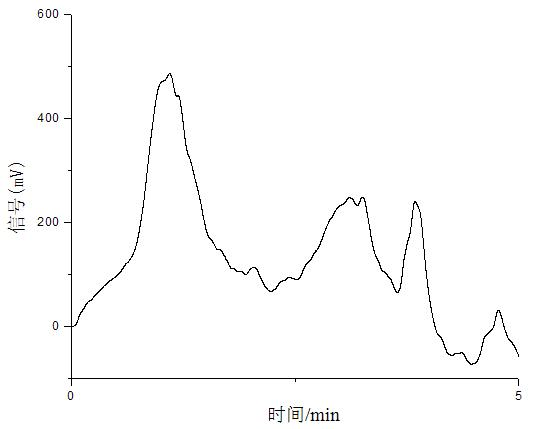

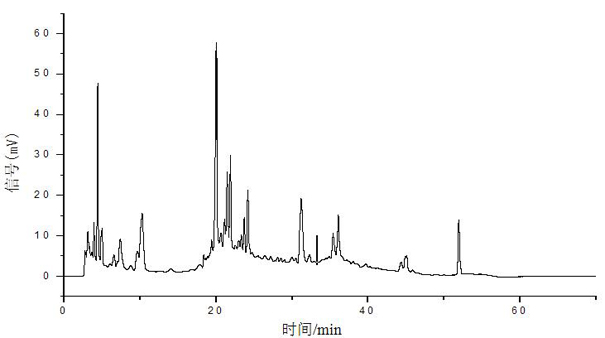

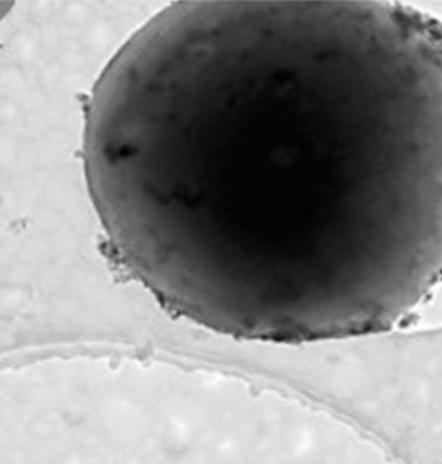

[0013] Specific embodiment one: the preparation method of the carbon-titanium dioxide chromatographic stationary phase of core-shell structure in the present embodiment is as follows: one, soluble ferrous salt and carbohydrate carbohydrate are dissolved in water, the soluble ferrous salt and carbohydrate carbohydrate The mass ratio is 1:2, seal with a plastic film, and then ultrasonic for 20-40 minutes, until the solution is completely clear and transparent, put it into a hydrothermal kettle, react with water at 155-165°C for 7-9 hours, and then follow the centrifugation and ultrasonic washing , centrifugation, ultrasonic alcohol washing and centrifugation for 2 to 4 times until the supernatant is clear, and dry at room temperature to obtain carbon spheres; 2. Add carbon spheres to TiO 2 In the sol, ultrasonic 20 ~ 40min, let stand for 10min, centrifuge; 3. Put the carbon spheres treated in step 2 in a tube furnace in N 2 Under protected conditions, the temperature is raised t...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that the soluble ferrous salt described in step 1 is ferrous gluconate, ammonium ferrous sulfate or lithium ferrous phosphate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the sugar carbohydrates described in step 1 are glucose, fructose, starch or oligosaccharides. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com