Efficient self-contained spring chuck key tool holder wrench

A tool holder wrench, spring-type technology, applied in the direction of wrench, screwdriver, tool holder accessories, etc., to achieve the effect of improving work efficiency, reducing labor intensity and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

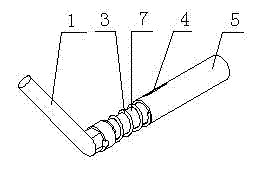

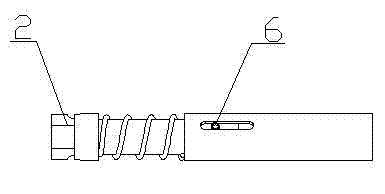

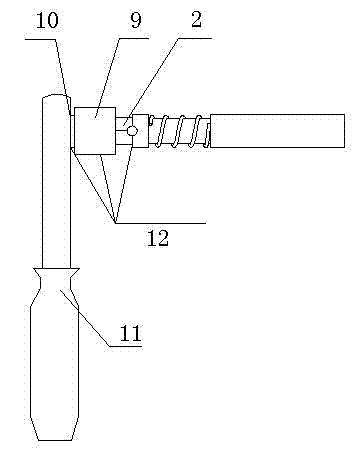

[0018] Such as figure 1 , figure 2 , image 3 As shown, a high-efficiency self-contained spring type chuck key tool holder wrench mainly includes: tool holder wrench 1, chuck key 7, and rotating device 12. It is characterized in that: tool holder wrench 1 and chuck key 7 Rotatably connected, the front end of the tool post wrench 1 is provided with a control button 8, a spring 3 protection device is provided between the rotating device 12 and the tool post wrench set 5, and the rotating device 12 is composed of a ratchet 10, a ratchet sleeve 9, an embedded nut 2 The upper end of the ratchet sleeve 9 is connected with the ratchet 10, and the lower end of the ratchet sleeve 9 is connected with the embedded nut 2. There is an elongated hole slot 4 on the side of the tool rest wrench set 5, and the bottom end is an inner square hole. When the wrench rotates, a force is given to make the ratchet 10 rotate, and the ratchet 10 drives the sleeve and the nut to rotate together. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap