Peel test roller and its method of rolling tape

A rolling machine and rolling technology, used in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of physical strength, insufficient rolling uniformity, and rolling speed that cannot be well controlled. , to achieve the effect of good repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

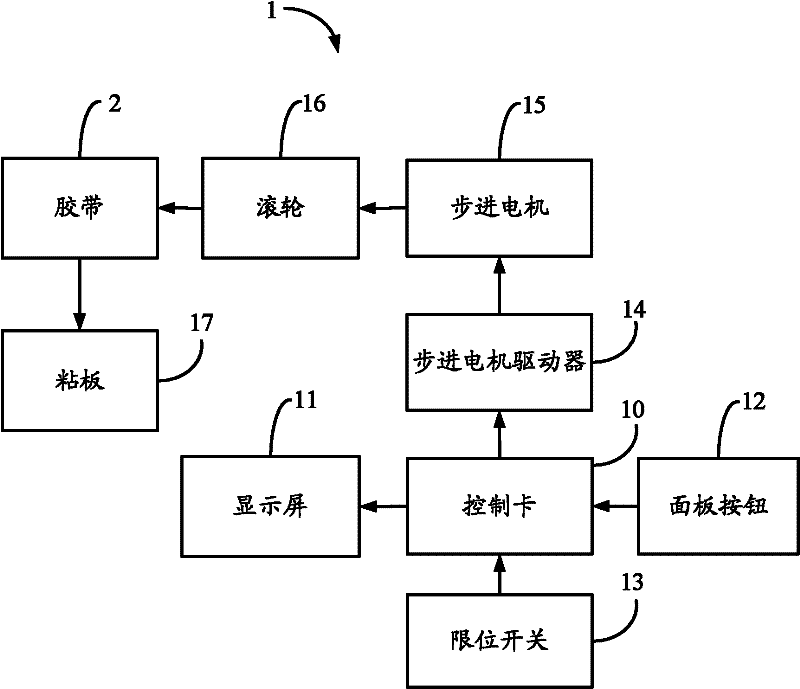

[0013] Such as figure 1 Shown is a structural block diagram of a preferred embodiment of the peeling test rolling machine of the present invention. The peel test rolling machine 1 includes a control card 10 , a display screen 11 , a panel button 12 , a limit switch 13 , a stepper motor driver 14 , a stepper motor 15 , a roller 16 and a sticky plate 17 . The display screen 11 , panel button 12 , limit switch 13 and stepper motor driver 14 are connected to the control card 10 , the stepper motor 15 is connected to the stepper motor driver 14 , and the roller 16 is connected to the stepper motor 15 .

[0014] The panel buttons 12 include a start / stop button, an edit button, and a save / down button. When each button is activated, its color will be different from that of other buttons. For example, when a certain button is activated, it will be lit.

[0015] The display screen 11 provides the user with an operation interface for setting the rolling parameters through the edit butto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com