Resistance heating evaporation source

A heating evaporation, resistive technology, applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve the problems of uneven material, evaporation material deposition, condensation heating, splashing to the substrate, etc., to achieve Avoid the effect of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

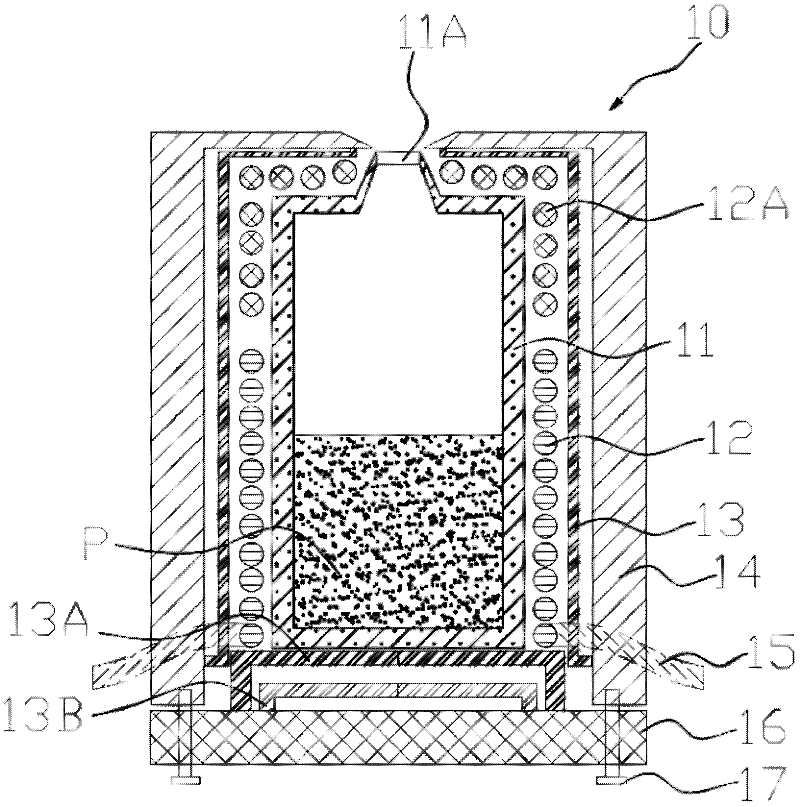

[0035] see image 3 shown. The resistive heating evaporation source includes a crucible 11 containing evaporation material P, an upper heating unit 12A located near the crucible evaporation port 11A, and a lower heating unit 12 located around the main body of the crucible 11 . The crucible 11 is preferably made of transparent quartz, and ceramic materials such as Al2O3, SiO2, PBN are optional; metal materials such as molybdenum and tantalum are optional; two independent heating units 12 and 12A are composed of metal wires or metal sheets, such as molybdenum wire , molybdenum sheets, etc., these two sections of heating units are controlled by two independent temperature measurement units and independent PID temperature control power supply. The evaporation source also includes the outer wall 14 of the evaporation source located outside the entire evaporation source, which is for The entire evaporation source is insulated from heat to prevent the loss of heat inside the evapora...

Embodiment 2

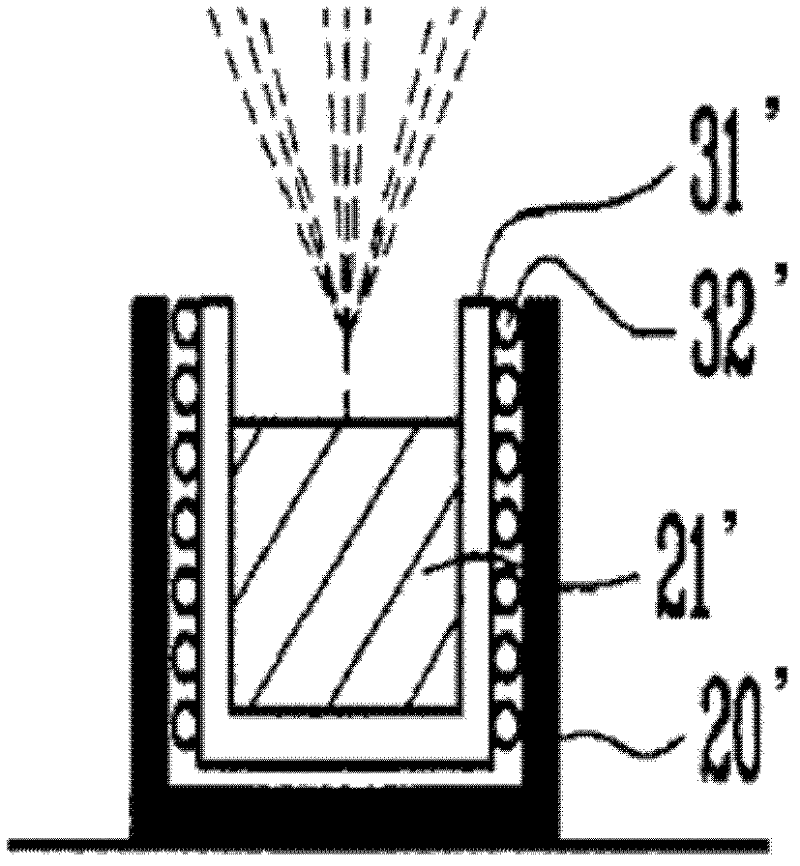

[0040] see Image 6 As shown, the resistive heating evaporation source includes a crucible 21 for containing evaporation materials, and also includes an outer wall 24 of the evaporation source located outside the entire evaporation source, which is to insulate the entire evaporation source and prevent heat loss inside the evaporation source. The source's supporting skeleton. At the same time, a heat shielding layer 23 , a first bottom heat shielding layer 23A and a second bottom heat shielding layer 23B are provided between the heating unit and the outer wall 24 of the evaporation source. Wherein 23A has the function of supporting the crucible 21 . The heating power line 25 is introduced from the side wall, and is generally made of copper wire, and the ceramic insulating sleeve is installed on the surface. The bottom 26 not only supports the crucible but also has good thermal insulation performance, and the material of the bottom is similar to that of the outer wall 24 . Th...

Embodiment 3

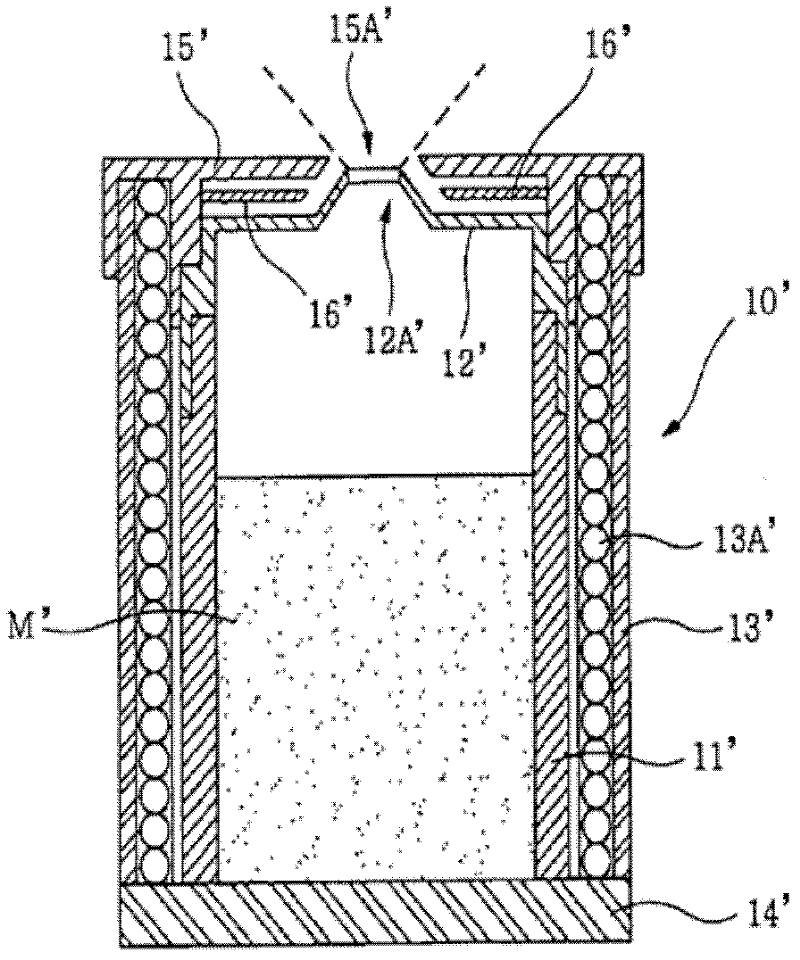

[0043] see Figure 7a As shown, the resistive heating evaporation source includes a crucible 31 for containing evaporation materials, and also includes an outer wall 34 of the evaporation source located outside the entire evaporation source, which is to insulate the entire evaporation source and prevent heat loss inside the evaporation source. It is also an evaporation source. At the same time, a heat shielding layer 33, a first bottom heat shielding layer 33A and a second bottom heat shielding layer 33B are also provided between the heating unit and the outer wall 34 of the evaporation source, generally made of a metal material with high reflection to infrared rays Made, including SUS (stainless steel), Ti, Mn; or add a layer of coating on the metal surface, such as Au, Ag, Al. Wherein 33A has the function of supporting the crucible 31 . The heating power line 35 is introduced from the side wall, and is generally made of copper wire, and the ceramic insulating sleeve is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com