Preparation method of in-situ self-generated titanium carbide particle reinforced nickel-based gradient coating

An in-situ self-generated, particle-enhanced technology, applied in coating, metal material coating process, etc., can solve the problem of difficult to obtain gradient coating, and achieve the effect of simple and effective process method, uniform distribution and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments.

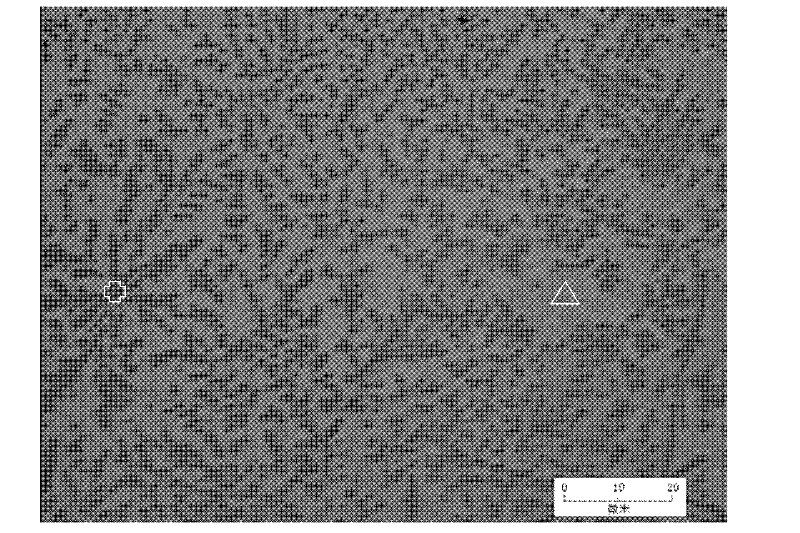

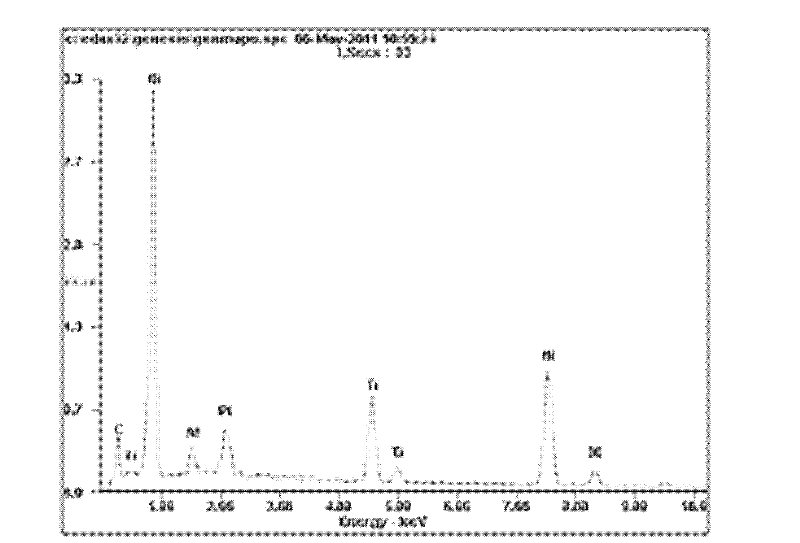

[0025] In this embodiment, nickel powder and carbon powder are used as the main raw materials of the cladding strengthening layer and supplemented with a small amount of other elements. Ti-4Al-6V is used as the matrix material and as the donor of titanium element. According to 85%wt of nickel powder, carbon powder 13%wt, other element powder: elemental aluminum powder 1%wt + yttrium oxide 1%wt for batching, the particle size of nickel powder is 200 mesh, the particle size of carbon powder is 2000 mesh, and the particle size of other element powder is 100 mesh;

[0026] Mix the above-mentioned powders and mill them mechanically for 24 hours to obtain a uniformly mixed powder;

[0027] On the base material Ti-4Al-6V, the mixed powder with a thickness of about 1.2mm is preset by cold pressing; the above mixed powder is reacted with the base material by laser cladding to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com