An all-in-one drying and ironing machine

An all-in-one machine and cover technology, which is applied to hand irons, household dryers, washing devices, etc., can solve the problems of low machine operation efficiency, reduced work efficiency, and increased labor intensity of operators, so as to reduce the occupied space. , The structure of the device is stable, and the effect of improving the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

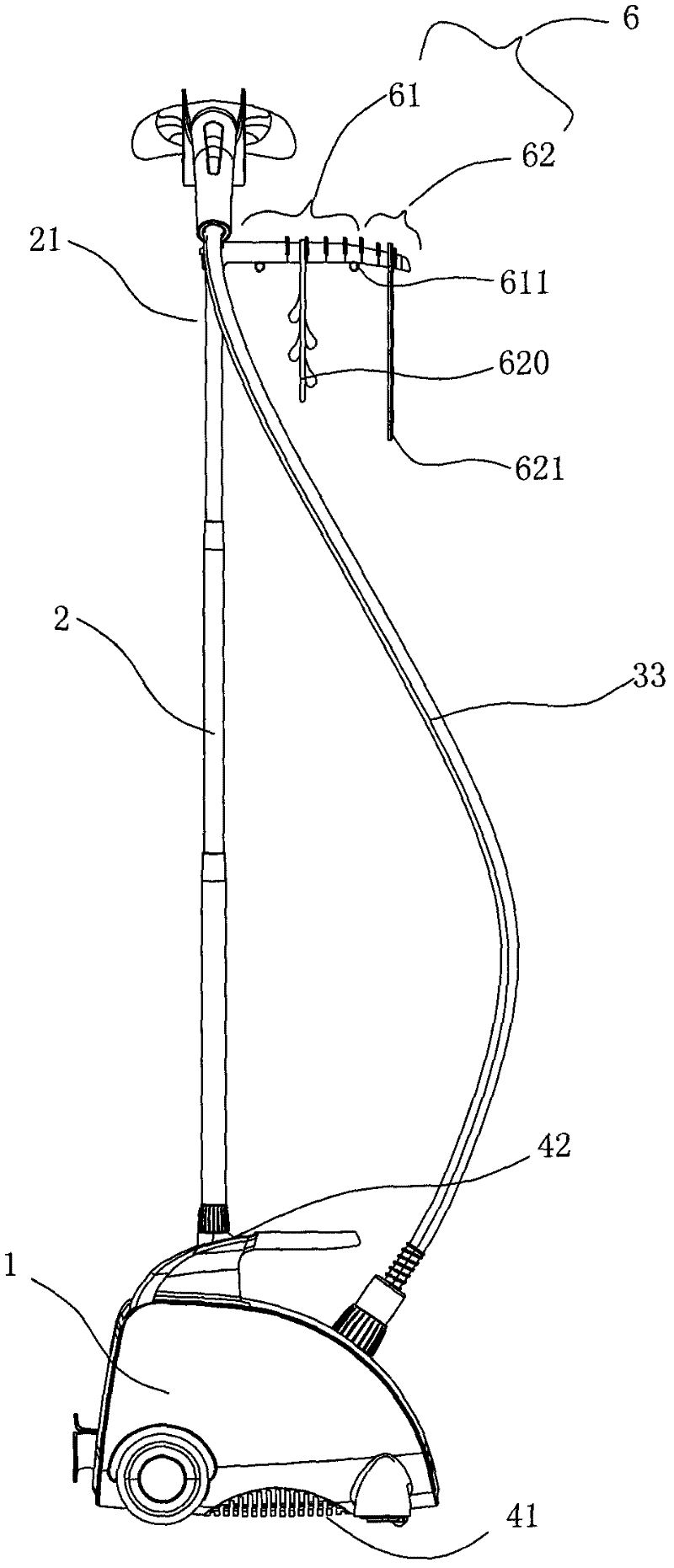

[0075] Such as Figures 1A-1H As shown, this integrated drying and ironing machine includes a support body 1 , a column 2 whose lower end is fixed on the support body 1 , a cover body 3 , and a bracket component 6 . Such as Figure 1A , 1F As shown, the bracket part 6 is located on the right side of the column 2 and is fixed on the upper end 21 of the column. The bracket part 6 includes a first branch arm 61 extending to the space direction on the right side of the column 2 for hanging and supporting the cover body 3 to hang down naturally, and The second branch arm 62 extending forward from the front end of the first branch arm 61, the front end of the second branch arm 64 extending to the external space in front of the front 32 of the cover body constitutes an ironing box for hanging and ironing clothes. Iron the hanging part 6A. The lower part of the first branch arm 61 is provided with a hanging ring 611 supporting the upper end of the cover body 3, so that drying clothe...

no. 2 example

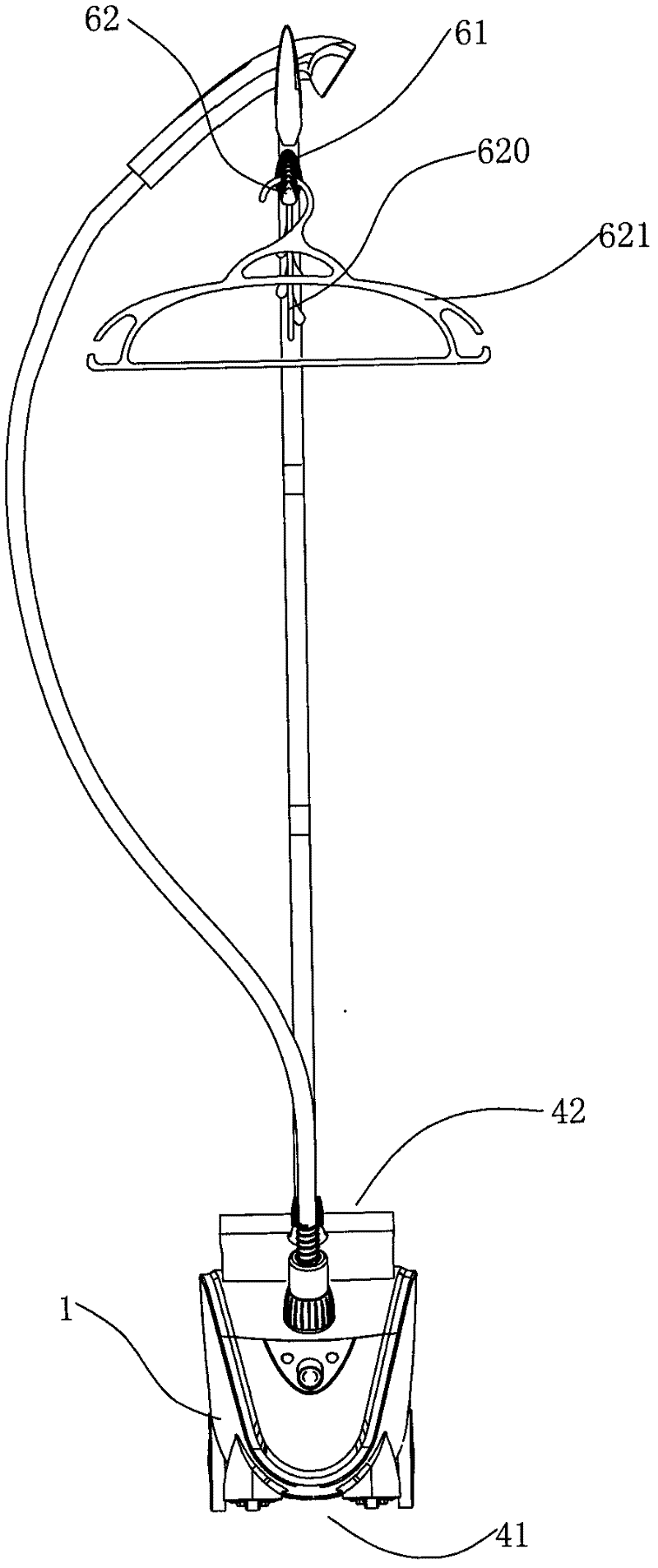

[0085] Such as Figures 2A-2C As shown, the difference from the first embodiment is that the bracket component 6 in this embodiment includes a first branch arm 61 extending toward the space on the right side of the column 2, and one end is fixed on the column at a distance above the first branch arm 61. , the second branch arm 62 whose other end extends in the same direction as the first branch arm 61 . The cover body 3 is suspended on the first branch arm 61 and keeps its back side 31 close to the side of the column 2, the cover body 3 hangs down naturally under the first branch arm 61, and the front end of the second branch arm 62 extends to the outside world in front of the cover body front 32 The space constitutes an ironing hanging portion 6A for hanging clothes to be ironed. Of course, in the above structure, the first branch arm 61 and the second branch arm 62 can be integrally fixed on the upper end 21 of the column.

[0086] Especially when the distance between the ...

no. 3 example

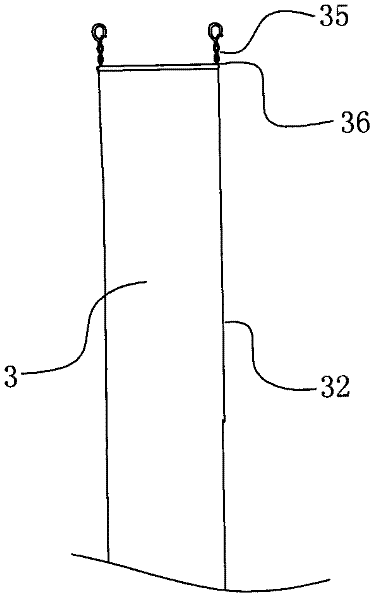

[0089] Such as Figure 3A-3D As shown, different from the above embodiment, the support ring 36 on the upper part of the cover body 3 is provided with a cross bar 37 along the short axis direction of the support ring 36, and the upper end of the hanger support device 620 is not fixed on the first branch arm. 61 but is fixed on the middle part 39 of the cross bar 37, and the dried clothes are directly hung on the hanger support device 620. The air outlet at the top of the cover body 3 can be some small air outlet structures; the opening of the cover body 3 can also be covered with a layer of mesh cloth, so that the flow of hot air flow discharged from the inside of the cover body 3 to the outside is controlled to keep the cover body There is a higher thermal temperature in the body 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com